Steel Division

In order to meet the climate targets of the Paris Agreement, an extensive decarbonization of industrial processes and industrial sectors is required to reduce global CO2 emissions by 2050. Moreover, billions of additional tons of CO2 from the so-called "hard to abate" sectors must be captured over the next few decades. However, this means that the current capacity of carbon capture and storage (CCS) projects will have to be multiplied from 2024 to 2050.

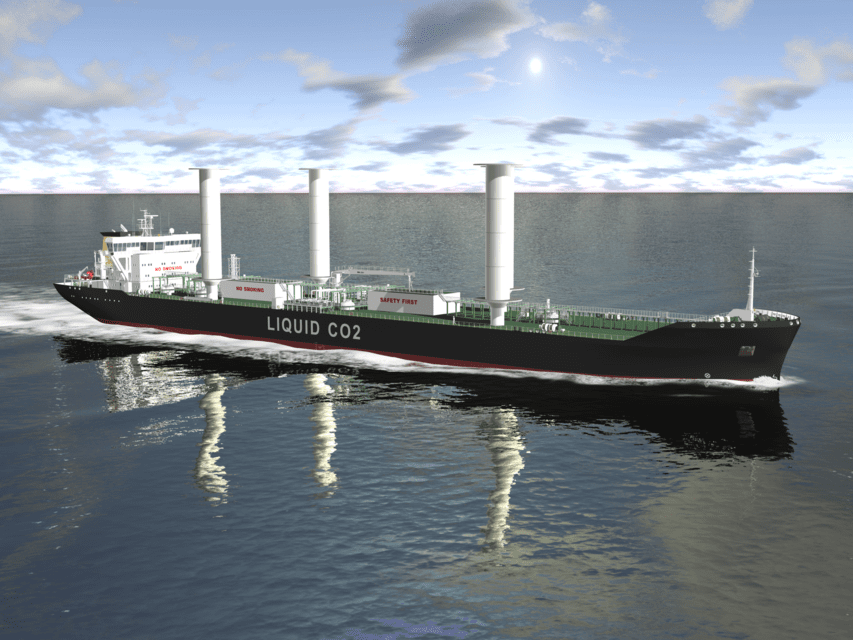

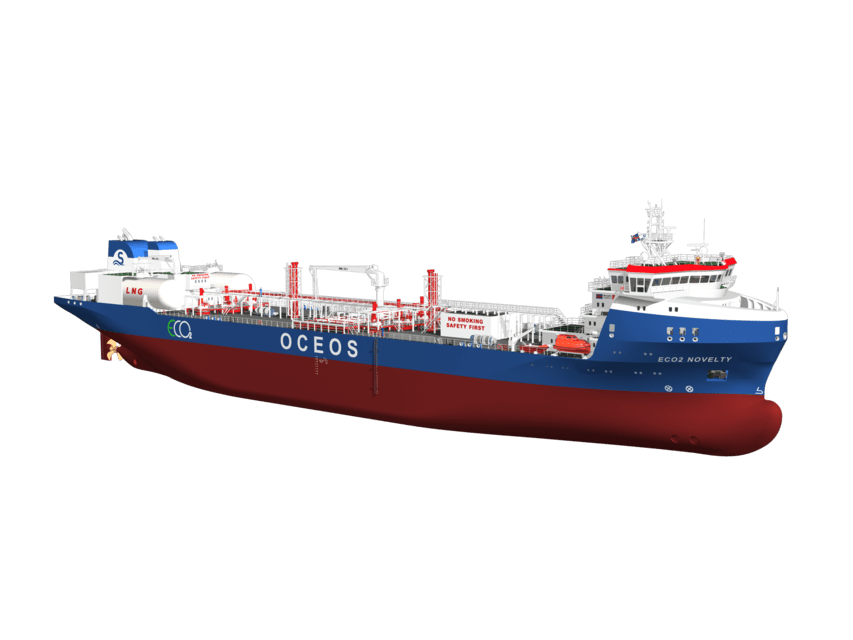

In addition, it is imperative to build a working infrastructure for CO2 transportation and storage.

We are ready for the coming changes in the value chain and offer a wide range of efficient specialty products for the areas of CO2 capture, transportation on the high seas, rail or road, as well as safe transportation via pipeline.

Building on the success of its high-performance F550 TMCP toughcore for medium-pressure LCO2 transport, voestalpine Grobblech GmbH is proud to introduce the F460 TMCP toughcore carbon steel that was specially designed for low-pressure LCO2 transports. This latest development highlights the commitment of voestalpine to delivering the safest and most efficient steel grades for the globally growing LCO2 value chain

The F460 TMCP toughcore material sets a new standard by offering up to a 40% increase in tank capacity compared to standard materials and thus maximizing cargo-to-weight ratio without requiring major modifications to the hull. This makes it possible for ships to transport larger quantities of LCO2 more economically over long distances—a significant advantage as low-pressure LCO2 transport projects expand worldwide.

Thanks to its exceptional strength and fracture mechanics properties, the F460 TMCP toughcore material yields excellent CTOD values, even at temperatures down to –55°C. This material is optimized to sustain the structural stress encountered during oversea transport.

By using F460 TMCP toughcore, operators achieve significant cost savings throughout the service life of the vessel and benefit from lower energy consumption per unit of transported volume.

This efficient approach aligns with the economy of scale, where larger vessel designs become more financially and environmentally sustainable.

Delivering the most comprehensive range of materials for high-, medium- and low-pressure LCO2 marine tanks, voestalpine Grobblech meets the evolving needs of the global carbon capture and storage industry.

Whatever one pays for a ship with yield type 355 tanks, it is 20 to 40% too much compared to a ship with high-strength tanks when calculated over the ship's lifetime

Regina Leidunger, Head of Sales Downstream

Especially for industrial processes that cannot be decarbonized, the neutralization of emissions through technologies such as amine scrubbers, TSA (Temperature Swing Adsorption), PSA (Pressure Swing Adsorption), ... is essential.

These processes place extreme demands on the corrosion resistance of the tanks and pipe material.

voestalpine Grobblech is the world market leader for roll-bonded clad plates with the best corrosion resistance and offers an intelligent and cost-effective alternative to solid stainless steel.

The clad plates are particularly suitable for the construction of absorbers and strippers of amine scrubbers.

A clad plate consists of a high-strength or ultra-high-strength carbon steel base material for static requirements and a cladding material made of stainless steel, which is characterized by the required corrosion properties.

By combining these advantages, remarkable cost savings can be realized in both material selection and processing. The first projects in the carbon capture sector are already being realized with clad plates from voestalpine Grobblech.

Trust in our quality and be a part of CO2 neutrality with us!

Among the various transportation options between capture sites and storage facilities, the role of liquid CO2 ship transportation will play a crucial role in the value chain.

Shipping offers a safe and flexible solution for transportation over long distances.

When transporting liquid CO2 (LCO2), it is important to consider the phase diagram of pure CO2 in order to make the right choice of material. According to the phase diagram, CO2 exists as a liquid between the triple point (minus 56.6 degrees Celsius, at a minimum pressure of 5.18 bar) and the critical point (31.1 degrees Celsius, at a pressure of at least 73.8 bar). This ratio has a significant impact on the design temperature of the tank and therefore also on the required properties of the heavy plates and welding consumables used.

voestalpine Grobblech's next generation carbon-manganese steel F550 TMCP toughcore replaces conventional nickel steel for LCO2 cargo tanks with significant project savings and the recently granted class approvals for F550 TMCP toughcore enable a highly efficient tank design for the transportation of liquid CO2 under medium pressure. The material impresses with a notched impact energy of 280 joules down to a temperature of -80°C, offering a new safety standard in the industry.

The lean chemical composition and extremely low nickel content of maximum 0.5% not only increases the commercial appeal of the material by reducing the impact of raw material price fluctuations, but also underlines our strong commitment to resource conservation and is an example of responsible material design for a sustainable future.

For effective CO2 management, a reliable and safe transportation from where it is produced to where it is used or stored is a must.

This requires the development of a multimodal CO2 transportation infrastructure and the transportation by onshore or offshore pipelines is particularly suitable for large quantities of CO2 and long distances from the point of origin to the destination.

In future, an extensive CO2 pipeline network will connect the large inland industrial clusters or industrial plants with the CO2 export terminals on the coast. These large quantities of carbon dioxide will either be transported to a final storage site (CCS), or by LCO2 transport ships or via offshore export pipelines, to be put to further use (CCU).

With its highly innovative heavy plates and state-of-the-art production facilities, voestalpine Grobblech forms the cornerstone for the rapidly growing infrastructure. The outstanding mechanical properties of our pipeline grades even meet the most stringent CO2 project requirements in terms of maximum toughness at the lowest temperatures or HIC resistance.