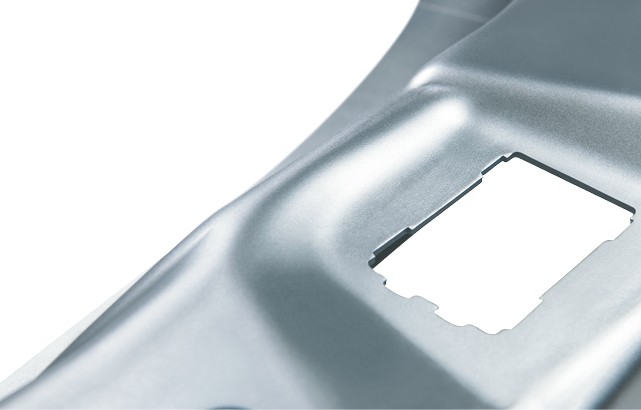

Steels for lightweight automotive design with convincing properties

voestalpine is a pioneer in the field of high-strength cold-forming steels, especially advanced high-strength steels (= ahss), and is pushing the limits of what can be done efficiently with innovative steel solutions in lightweight automotive design. The old rule that tough materials are hard to form no longer applies in our view. Our material, manufacturing and processing expertise under a single roof forms the basis for the development of steels that set standards in their properties, formability and efficiency in component production.

Comprehensive portfolio for structural and body components as well as exposed panels

Whether safety and crash-relevant components, structural or body parts or exposed panels – we have the optimum steel for the required properties in terms of yield strength, tensile strength, total elongation, resistance to edge cracking, bendability and suitability for deep drawing. Our technical specialists will be happy to provide professional consultation.

Wide range of total elongation and tensile strength

Comparison of ahss classic and ahss high-ductility property profiles

Comparison of material and performance facts

Which steel for which requirement? The downloads will provide us with answers.

Material facts: ahss dual-phase steels and ahss complex-phase steels in comparison: What are the differences in yield strength, total elongation, resistance to edge cracking, and how suitable are these steels for deep drawing and bending operations?

Performance facts How do ahss classic steels differ from ahss high-ductility steels in terms of forming properties, welding suitability and crash behavior?