Our steels in good part for your success

Whether for structural components, crash-relevant safety parts or exposed panels with the highest surface quality, we always offer only one solution for every requirement in automotive lightweight design: the best one. This guarantees a comprehensive portfolio of high-quality steels for cold and hot forming.

The best solution with the most professional consultation

Whether cold forming with ahss-steels or hot forming with phs technology (press hardening steels), the technical specialists at voestalpine will assist you with their expertise in high-strength steel grades, production engineering and product and process development. Because different components have different requirements. The following graphics show which ultralight material is the ideal light-weight solution for exposed panels and interior components.

Applications

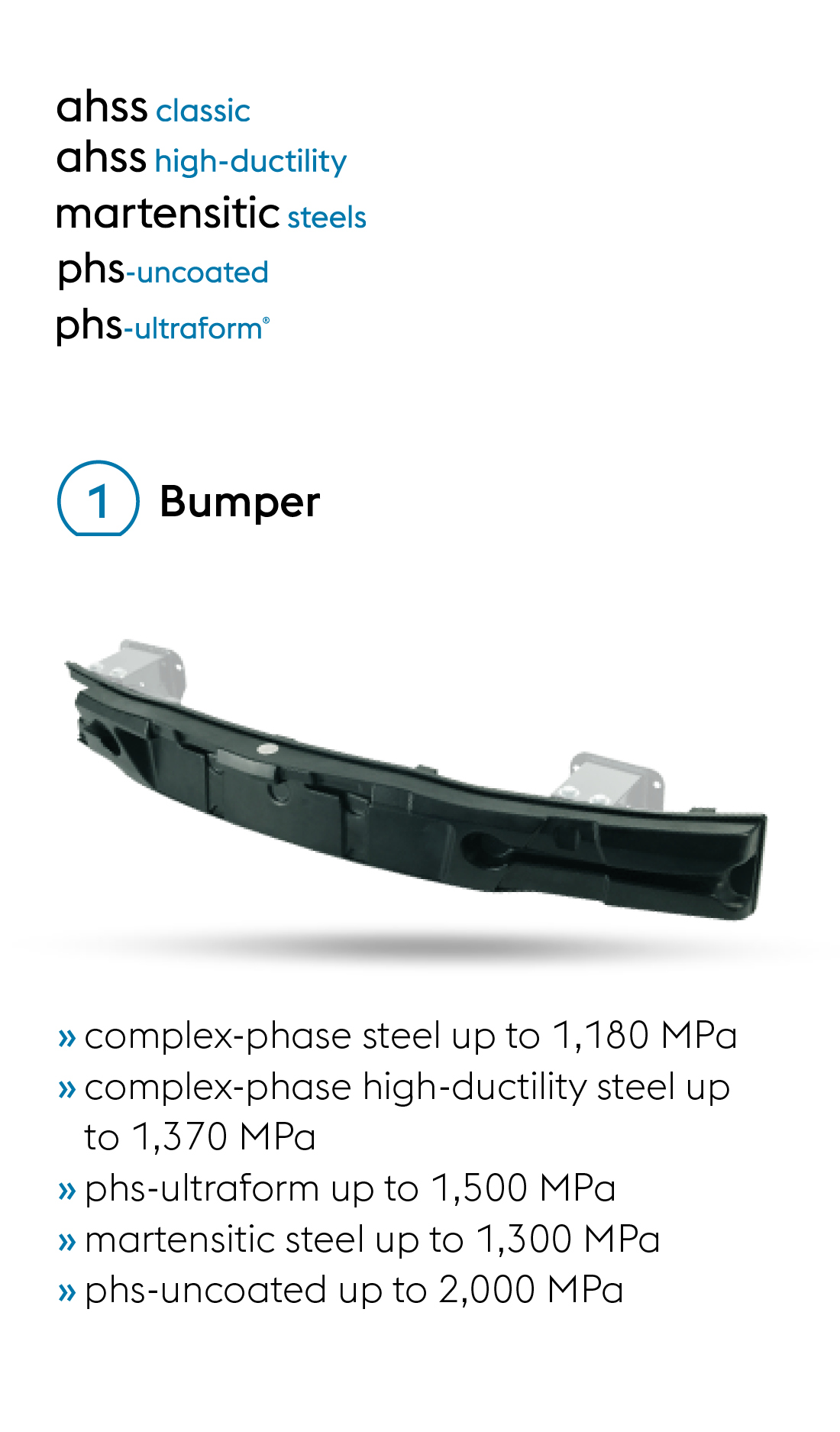

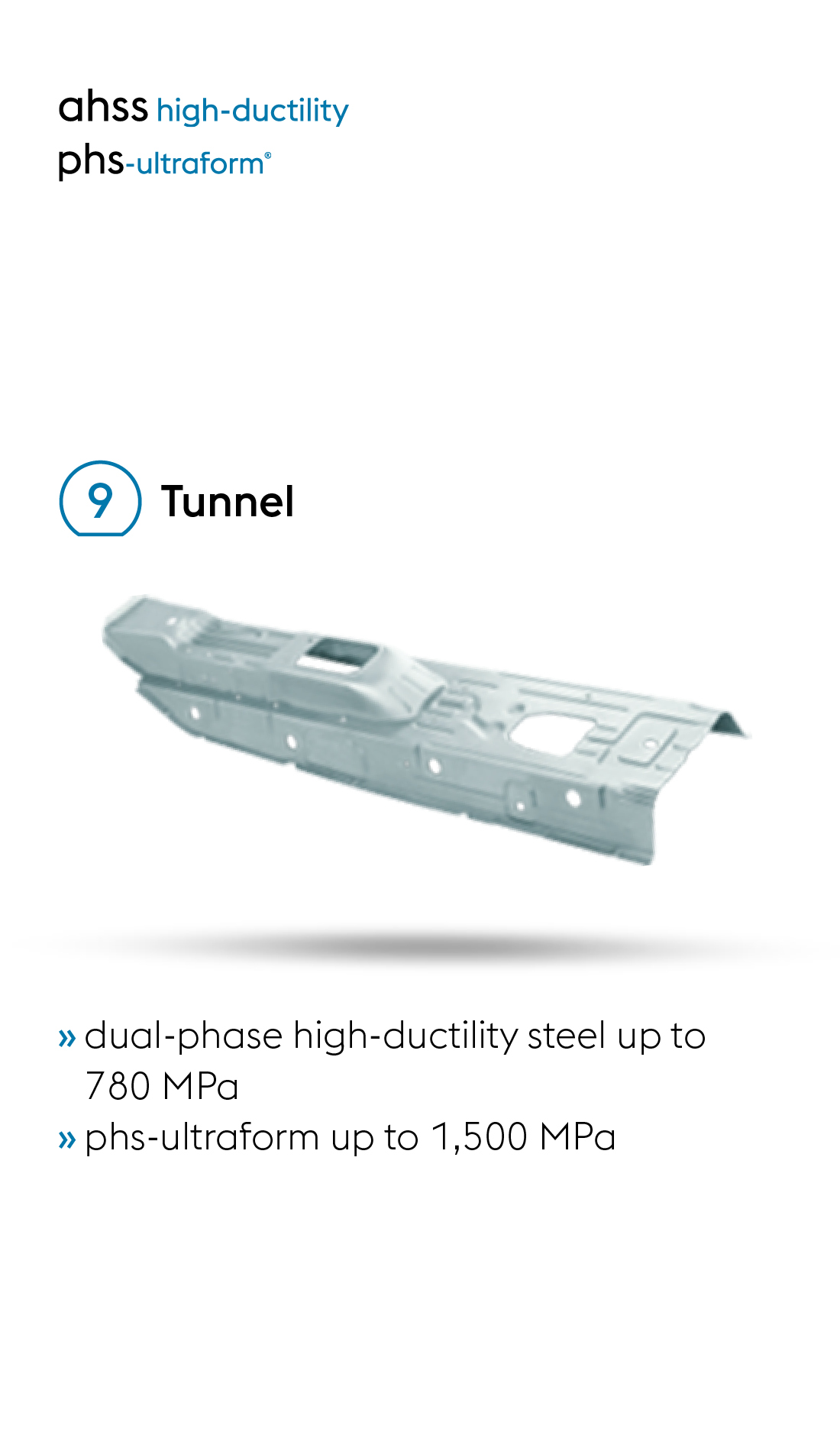

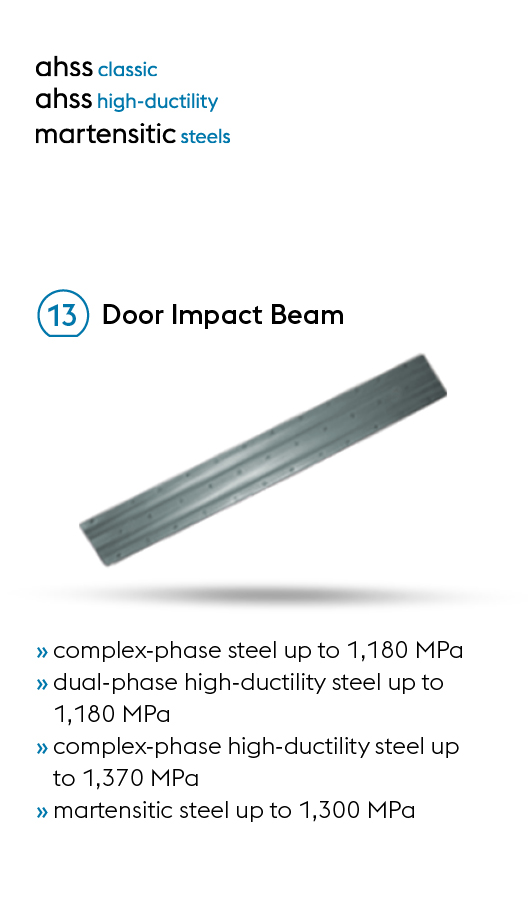

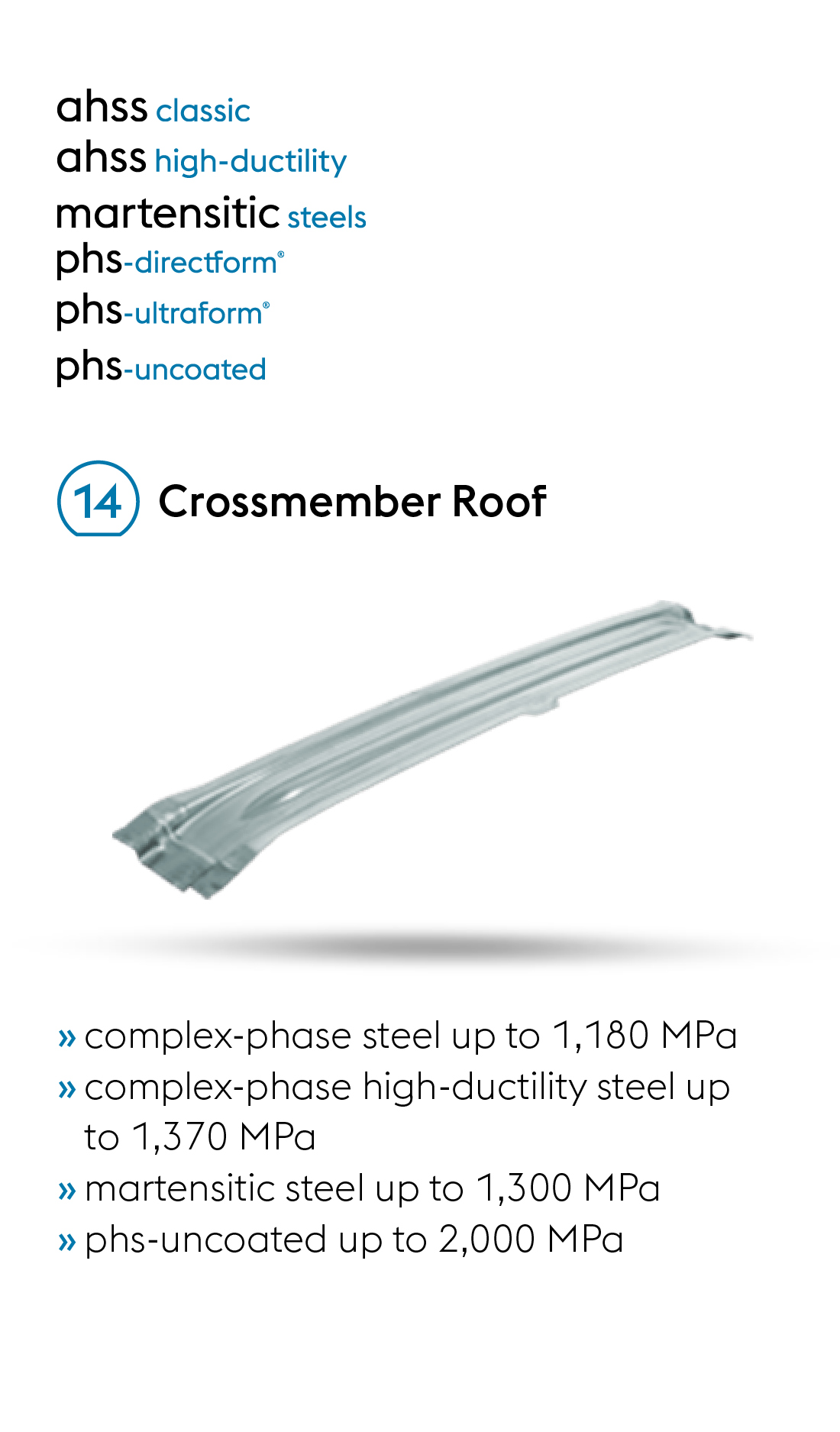

- Interior components Side member front, middle, rear, crash box, bumper, A, B and C pillar, seat structure, cross member, tunnel, roof frame, roof bows, rocker panels, door impact beams etc.

- Exposed panel components Mudguards, hoods, door panels etc.

Exemplary applications for internal parts

Exemplary applications for exposed panels

Your success is our goal

Whether for high-strength solutions in lightweight automotive design or for questions about cold and hot forming – our experts are at your side with expertise and experience. Together we will find the best solution for your requirements. Talk to us!