Onze missie: 0% CO2-emissies tegen 2035

De klimaatverandering is de grootste uitdaging van onze tijd. We nemen de handschoen op en stellen ons het doel om de Metal Forming Division CO2-neutraal te maken tegen 2035. Want pas als iedereen in de waardeketen zijn taak vervult, kunnen we samen ons gemeenschappelijke doel bereiken.

Vandaag al lopen op onze vestigingen wereldwijd talloze projecten om energie te besparen, processen te optimaliseren, over te schakelen op groene stroom of zelfs op zelf opgewekte hernieuwbare energie, en onze leveranciers te motiveren om eigen klimaatprogramma’s door te voeren.

Onze visie: de Green Factory

In de toekomst zal het niet alleen doorslaggevend zijn wat je als bedrijf produceert, maar ook hoe CO2-arm je het produceert. De Metal Forming Division heeft daarom als doel gesteld om tegen 2035 CO2-neutraal te produceren. Een allesomvattende aanpak en het samenspel van alle maatregelen op belangrijke gebieden leidt tot het meest duurzame resultaat en maakt van de Green Factory een realiteit. De Green Factory is het streefdoel voor elk van onze vier businessunits. Aangezien de units niet alleen verschillen op het vlak van hun productportfolio maar ook qua processen, werkstappen en productiemethoden, heeft de Green Factory verschillende gedetailleerde kenmerken voor elke unit. Klik door de businessunits van de Metal Forming Division en ontdek waar en hoe CO2-uitstoot wordt vermeden:

Green Pre-material—greentec steel

Wind Energy

Recycling Material

Hydro Power

Green Logistics

Process Optimization:

e. g. LED Lighting

Job Bicycle

Photovoltaic Energy

E-vehicle Fleet

Cold Forming

Hot Forming

Laser Welding

Stamping

Painting

Assembly

e. g. LED Lighting

Green Pre-material—greentec steel

Wind Energy

Recycling Material

Hydro Power

Green Logistics

Job Bicycle

Photovoltaic Energy

E-vehicle Fleet

Finishing

Joining technology

Heat Treatment

Forming

Cold Rolling

Biomass energy

Green Pre-material—greentec steel

Photovoltaic Energy

Wind Energy

Recycling Material

Hydro Power

Green Logistics

Process Optimization: e. g. LED Lighting

Job Bicycle

E-vehicle Fleet

Roll Forming

Cold Drawing

Pre-processing

Painting

Slit Strip

Process Optimization: e. g. LED Lighting

Green Pre-material—greentec steel

Photovoltaic Energy

Wind Energy

Recycling Material

Hydro Power

Green Logistics

Job Bicycle

E-vehicle Fleet

Edging, Punching,

Drilling

Roll Forming

Edging, Punching,

Bohren

Engineering & Project Handling

Pre-processing

Slit Strip

Environmentally certified suppliers

Welding

Welding

Galvanizing

Assembly

Stamping

Stamping

Road Safety Systems

Half-finished Material

from Tubes & Sections

Rack Systems

Process improvements and technology changes are the royal class of CO₂ reduction. In most cases, not only CO₂ but also a lot of energy is saved here. Examples are LED lighting instead of conventional lighting, synchro motors instead of hydraulics, solid-state lasers instead of CO₂ lasers, and many more.

Large PV systems can be found on many of the Metal Forming Division's roofs. The electricity generated at the top of the roof is used to form our metals a few meters below. We want to generate up to 20% of our electricity consumption ourselves in the future. We are already well on the way to achieving this goal.

Compared to PV systems, electricity from wind turbines can be produced more efficiently and, above all, independent of the time of the day and the season. Individual plants of the Metal Forming Division have therefore concluded a long-term supply contract with a wind farm near voestalpine sites in 2023.

Hydropower is characterized by high continuity (day-night, winter-summer). One of the largest companies in the Metal Forming Division has been operating its own hydropower plants for years, which are directly connected to the plant.

The bicycle is the environmentally friendly, sporty alternative to the fossil-fueled car and is also used to cover larger distances within the company at larger production sites. In addition to bike racks, we have attractive leasing bike offers for our employees. Those, who also use their bike in their free time, are even doing something good for their health.

We have been using electric forklifts in our intralogistics for many years. With charging stations on the factory premises, both employees and business partners can charge their e-vehicles. The share of e-vehicles in the company fleet is being successively increased.

We hebben de CO2UNTDOWN TO ZERO gestart!

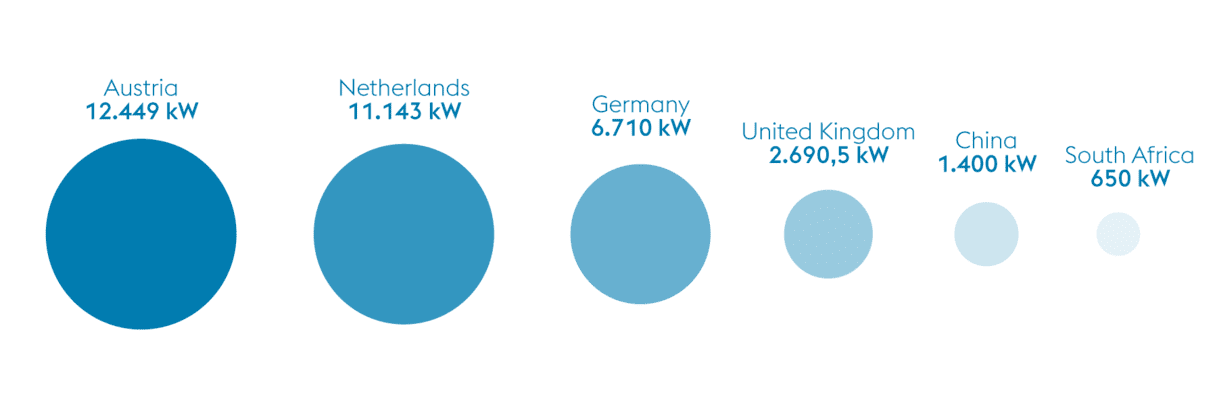

We wekken onze eigen elektriciteit op (in MWh/a):

Installed PV-capacity at our sites

Onze CO2-roadmap

Energie besparen en processen verbeteren

Energie die niet wordt verbruikt, kan ook geen uitstoot veroorzaken. Daarom proberen we energie te besparen waar dat ook maar kan. Dat willen we realiseren door onze productieprocessen en de infrastructuur van onze vestigingen voortdurend te verbeteren.

Bijvoorbeeld door restwarmte van het productieproces te gebruiken om kantoorgebouwen te verwarmen, of door de isolatie te verbeteren.

Overschakelen op hernieuwbare energiebronnen

Het opwekken van elektriciteit veroorzaakt CO2-emissies omdat de stroom nu eenmaal niet zomaar uit het stopcontact komt.

Daarom zijn we al begonnen om over te schakelen op elektriciteit uit hernieuwbare energiebronnen. Enkele Oostenrijkse en ook Braziliaanse vestigingen gebruiken nu al uitsluitend groene stroom. Onze andere vestigingen zijn goed op weg om dit doel ook te bereiken.

Zelf groene energie opwekken

Alleen hernieuwbare energie inkopen is voor ons niet genoeg. We produceren haar ook daar waar zij nodig is: in onze fabrieken. Hiervoor worden grootschalige fotovoltaïsche systemen geïnstalleerd op daken, muren en in open ruimtes. Waar mogelijk gebruiken we ook waterkracht.

In onze vestigingen in Bunschoten (Nederland) hebben we bijvoorbeeld al het grootste fotovoltaïsche systeem van het land. Door de installatie van 35.000 zonnepanelen hebben we er intussen al 5.700 ton CO2 bespaard.

De CO2-waardeketen optimaliseren

Emissies worden niet uitsluitend gegenereerd door onze productieprocessen. De productie van voormaterialen als plaatstaal en aluminium is soms een zeer belangrijke bron van CO2-uitstoot. Maar ook het transport van goederen heeft een impact op het klimaat.

Daarom letten we er goed op waar welk deel van de CO2-uitstoot vandaan komt en hoe we in de hele waardeketen nog meer CO2 kunnen besparen. Zoals bij het transport, bij voorproducten of bij het inkopen van materialen bij leveranciers die, net als wij, een CO2-reductieplan hebben.

Het milieubewustzijn versterken

Omdat we elke kans willen grijpen om zoveel mogelijk CO2 te besparen, hebben we tal van projecten gelanceerd om ons engagement ook uit te dragen tot buiten de poorten van onze vestigingen.

CO2 is de „nieuwe valuta“. We vinden het niet altijd even gemakkelijk om met deze valuta om te gaan. Iedereen weet ongeveer wat een liter melk, een kilo rundvlees, een liter diesel of een fiets kost. Maar wie weet hoeveel CO2 deze producten veroorzaken tijdens hun productie? Deze kennis van de CO2-voetafdruk legt echter de noodzakelijke basis voor een klimaatbewust optreden. We willen hiertoe een bijdrage leveren en stellen daarom milieuproductverklaringen op die de CO2-voetafdruk van onze producten vermelden. We hebben ook onze eigen CO2-calculator uitgewerkt die we graag als hulpmiddel delen met ontwikkelaars, medewerkers en klanten. Wie niets weet, moet immers alles geloven. En: wie zijn CO2-voetafdruk niet kent, „denkt alleen maar“ dat hij milieubewust handelt. Doe zelf de test: wat veroorzaakt meer CO2? 1 kg rundvlees, 1 kg staal, 1 kg aluminium of 1 liter melk? Hoe zeker ben je?

Meer

Meer