Our FOXcore GUARD rutile stainless steel cored wires with the product names FOXcore GUARD 308L-T1, FOXcore GUARD 309L-T1 and FOXcore GUARD 316L-T1 help to protect your workplace by significantly reducing the Cr (VI) content in the welding fumes and helping to meet recently revised exposure limits.

Up to 90% less Chrome (VI) - Our FOXcore GUARD range

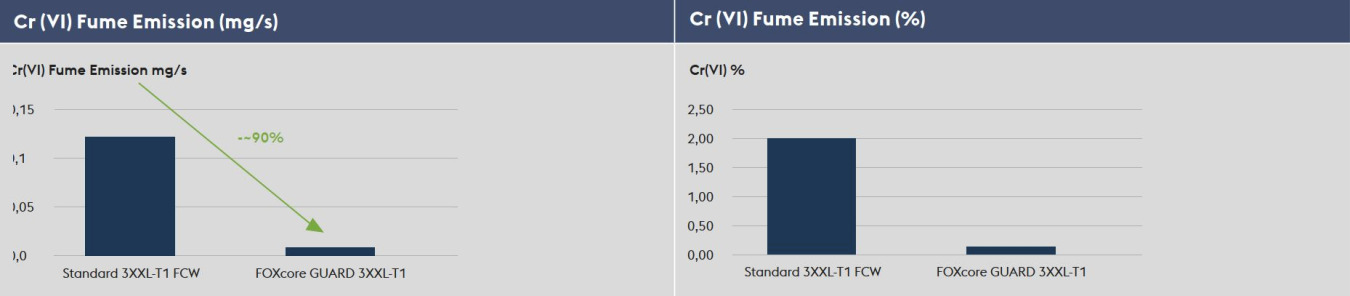

We revolutionize welding with our FOXcore GUARD range – 90% reduction of Cr (VI) in welding fumes for improved welders’ health and safety.

Benefit from high productivity and performance combined with lower Cr (VI) fume emissions

- FOXcore GUARD range can be used in all positions

- Good slag detachability

- Little spatter formation

- Good resistance to general, pitting and intergranular corrosion in chloride containing environments

- Suitable for service temperatures from –196°C to 400°C, depending on which welding wire is selected from the FOXcore GUARD line

- Up to 90% less Chrome (VI)

As part of a holistic approach, voestalpine Böhler Welding has developed innovative welding consumables to significantly reduce the harmful components contained in welding fumes. After all, it is not possible to work entirely without welding fumes or necessary elements in the filler metal such as Manganese or Chromium.

In September 2023, the first welding consumables were presented in Europe that reduce Manganese in welding fumes by more than 60 % now we are proud to present our consumable range with significant reduction of hexavalent Cr (VI) in the welding fume by 90 % respectively.

FOXcore GUARD line, High-alloyed, austenitic stainless multi-positional flux-cored wires are able to reduce operator exposure from airborne Cr (VI) emissions and will assist in meeting recently revised exposure limits. Less than 0.006 mg/s Cr (VI) forms with Ar + 18% CO2 as shielding gas, which is approximately 90% lower than for conventional flux-cored wires.

Expert statements

We met Andrea M. and Sebastian L. part of the research and development team to get some insights on the development process of our FOXcore GUARD wires.

All the metallurgical expertise of the

development team was required to find fewer

critical elements that would still guarantee the

desired properties. The aim was to develop

"healthier" cored wires that are in no way inferior to the standard products from voestalpine Böhler Welding. As these products must have the same

mechanical properties as well as acceptable

welding behaviour and productive processing for our customers, it was a major challenge to fully meet all three points,

recalls Sebastian L.

At the start of the project, a lot of time was invested in extensive literature research and the first samples were also produced. We then analyzed these in terms of flue gas quantity and composition as well as welding performance. This provided us with information about possible directions in which the development could go,

explains Andrea M.

FOXcore GUARD in action

For further technical details please consult our datasheets or our product management team.