The environment benefits already during the proprietary production process of ECOspark® wires by leaving out the coppering process where normally environmental critical baths and substances are used.

Excellent arc stability and productivity - from uncoppered wires to ECOspark®

ECOspark® solid wires are not only copper free welding wires, but the result of continuous improvement of this technology. Replacing the conventional copper layer by the engineered ECOspark® surface makes a difference to productivity and sustainability at the same time. Generating a lower amount of welding fume with practically zero copper the welding environment gets less harmfull.

ECOspark® is not only resource efficient - Discover all the benefits.

ECOspark® wires offer the benefit of higher productivity having the capability to deal with higher welding currents especially in combination with Böhler Arc welding processes such as QuickPulse resulting in higher deposition rates, increased welding speed and shorter production time.

Wires with ECOspark® surface are the state of the art non coppered solid wires for manual and robotized welding.

That’s the motivation to write the “ECO” in ECOspark® in capital letters:

- ECOfriendly and ECOnomic.

- Wide scope of applications: ECOspark® wires carry multiple approvals with service temperatures of -50°C.

- ECOspark® 460 is even approved by DNV with grade IV YS for ships and offshore units.

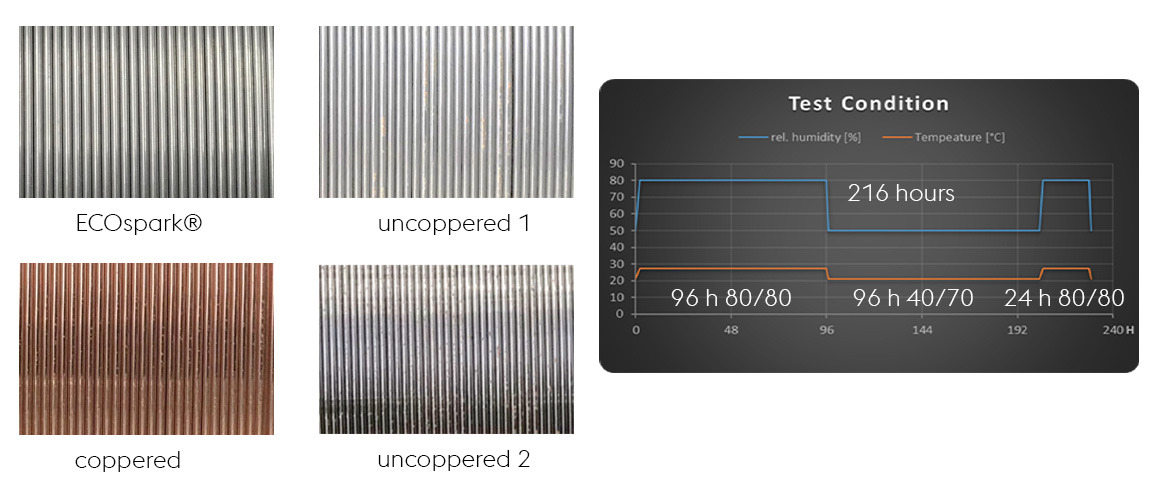

The long term storage capability of wires with the ECOspark® surface has been proved by numerous customers around the globe and during a climate chamber benchmark simulating transport and handling under severe conditions. Already during the 216 hours test, some of the benchmarked wires started to show surface corrosion. ECOspark® 420 and 460 showed a far better protected wire surface than other uncoppered or coppered wires.

The feedback from many benchmarks and welding shops can be summarized as follows:

| ECOspark® wire surface |

|

| Reliable arc ignition |

|

| Stable arc within wide parameter range |

|

| Stable feding properties |

|

| Less silicate surface residuals |

|

| Stable BS300 (S) spool |

|

Environmental Product Packaging

ECOspark® is available with different spools and drums, for highly productive wire supply in automated welding.

ECOdrum – made entirely from easy to recycle materials, like carton. The empty drum can be folded flat for space saving storage and easy disposal.

For more information on ECOspark® wires, drum and wire guiding systems please consult our datasheets and brochures.