Electroslag Strip Cladding with High Recovery Flux

Maximizing deposition rates and lowering strip consumption — A perfect solution for clad pipe manufacturers. We had the opportunity to sit down with Claude Bouillot, Product Manager for Strip Cladding and an experienced professional in welding and cladding, to discuss the development of our new high recovery flux for electroslag strip cladding.

Meet Claude Bouillot - a dedicated expert with nearly three decades of experience in the welding industry. With a doctorate in Material Science, Claude has honed his skills in various roles, including Product Manager and Industry Segment Manager for the energy sector. Since 2017, he has been driving innovation as the Business Development Manager for Strip Cladding Solutions at voestalpine Böhler Welding. Claude's extensive metallurgical knowledge, coupled with his deep understanding of welding and cladding processes, makes him a trusted partner for manufacturers. His passion for delivering tailored solutions ensures customers receive the right support to enhance productivity and achieve optimal results.

Could you give us a brief introduction to strip cladding processes in general? What types of processes exist?

There are two main processes in strip cladding:

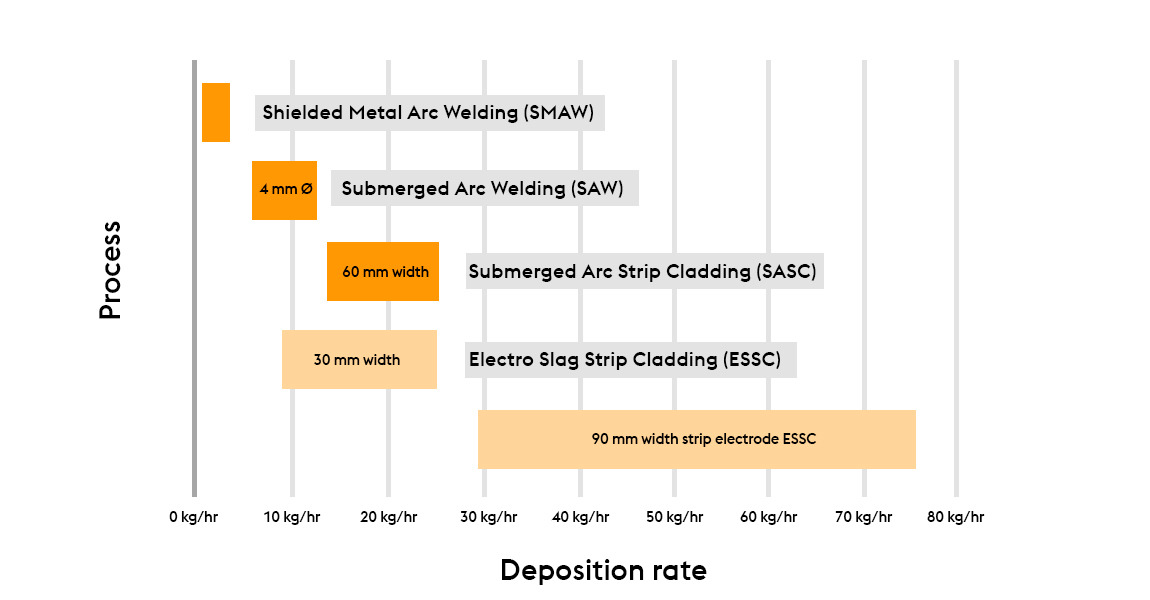

- Submerged Arc Strip Cladding (SASC): As the name suggests, SASC uses an electric arc and a non-conductive submerged arc welding flux for fusion. With a 60 mm wide strip, deposition rates typically range from 12 to 25 kg/hr.

- Electroslag Strip Cladding (ESSC): Unlike SASC, ESSC employs a conductive flux and operates without an electric arc, relying on heat-resistant fusion instead. This method allows deposition rates to reach up to 50 kg/hr with the same 60 mm strip width.

Strip Cladding Process Productivity

Can you also give us an overview of the industries and applications in which strip cladding is most commonly used?

Strip cladding is widely used for cladding large surfaces, such as pressure vessels, valves, pipes, reactor vessels, and pipelines in industries like oil and gas, chemical processing, and power generation. Typically, these components are made from unalloyed base metals, and cladding is applied to the inside or outside to ensure the required corrosion resistance for each specific environment. In addition to new fabrications, strip cladding is also applied in maintenance and repair, particularly in the forging and steel industries for components like continuous casting rollers

Next up, could you give us some insight into the High Recovery Flux? Why it was developed, and what benefits does it offer?

One of our customers in the clad pipe industry approached us with a request to improve the productivity and reduce costs of the Electroslag Strip Cladding (ESSC) process. Currently, the clad pipe market is experiencing steady growth, driven by demand from sectors such as oil and gas, chemical processing, and power generation. Clad pipes are composite pipes that combine a corrosion-resistant alloy, like stainless steel or nickel-based alloys, which is cladded onto the inner surface of a carbon steel pipe. This combination allows the pipes to withstand harsh environments with high temperatures, pressure, and corrosive substances, while keeping costs down by using carbon steel as the base material.

Due to this market growth and increased competition, manufacturers are seeking ways to boost productivity while also lowering manufacturing costs.

And what are the specific benefits of the High Recovery Flux for these manufacturers?

The benefits are significant. Our High Recovery Flux is highly alloyed, has the characteristic of further increasing the deposition rate, and enables a reduction in strip consumption of around 15%. This is important because the cladding strip - often alloyed with costly elements like Alloy 625 - is a major expense. By reducing strip consumption, we can substantially lower costs for clad pipe manufacturers.

How else does your team support customers in improving productivity and their strip cladding process?

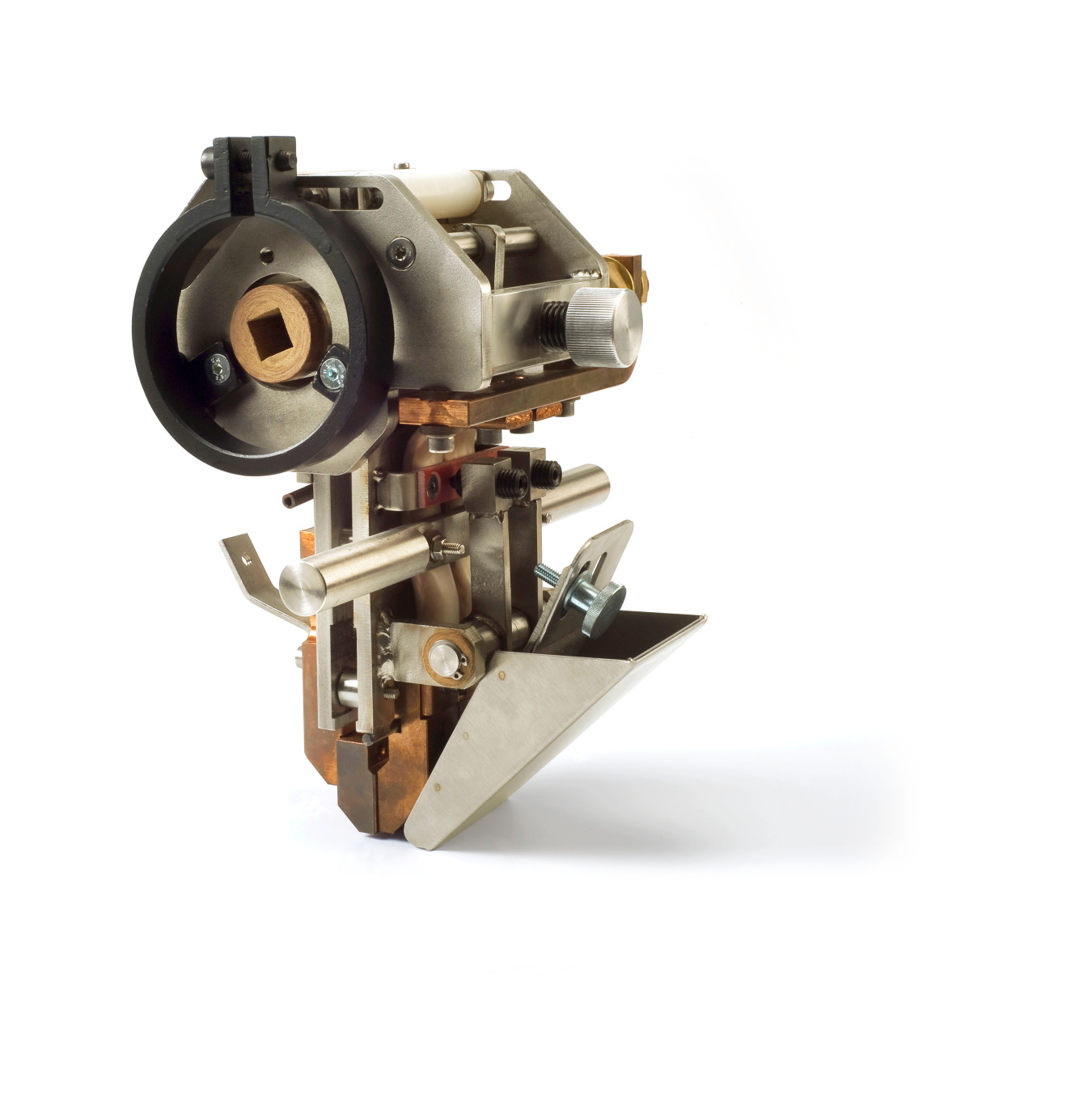

We provide comprehensive metallurgical support and assistance during the process itself. Our Strip Cladding heads for both ESSC and SASC ensure continuous feeding and alignment, and they are designed for easy installation on all power sources. This makes it easier for our customers to integrate and optimize their strip cladding operations.

Interested in finding out more? Please contact our strip cladding expertes for support.