Press Hardening

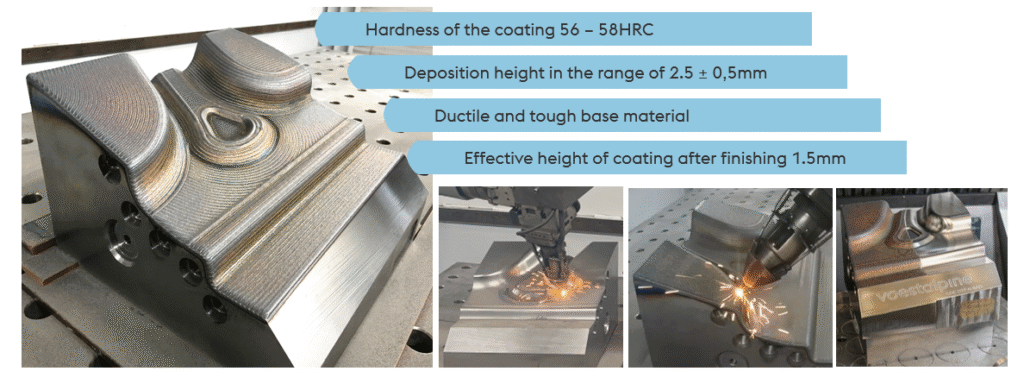

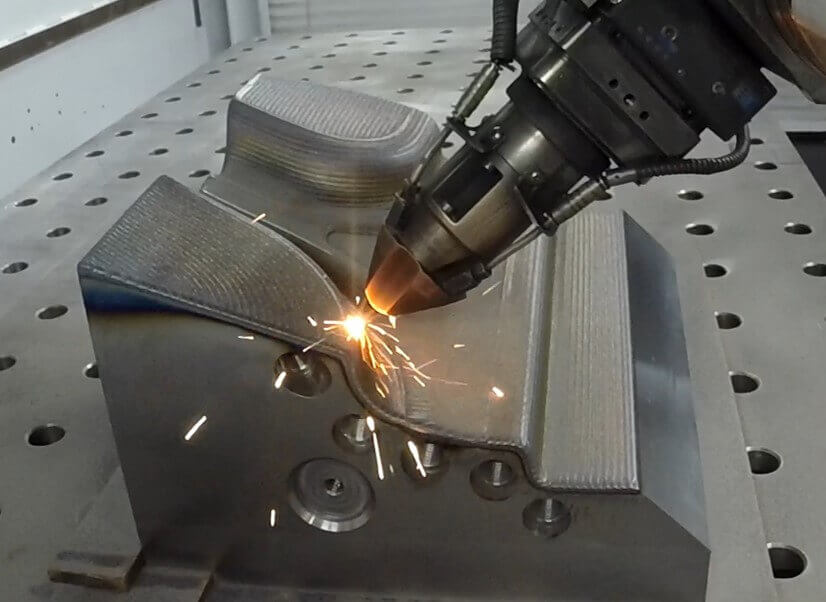

Coating of tool segments for press hardening using laser deposition welding

Internally cooled tools for the direct press hardening of high-strength sheets are subject to a complex range of loads. For example, abrasive wear, especially on the outer radii, leads to insufficient sheet metal contact and, as a result, impaired heat transfer. This ultimately results in rejects of components due to dimensional deviations caused by the springback of the sheets. Furthermore, the materials used for the tools must have a high resistance to cyclic thermal cycling in order to avoid cracks forming on the surface. In addition, due to the fact that press-hardened sheets are usually coated with AlSi as standard, adhesive wear occurs, which requires regular, manual polishing cycles. The wear mechanisms mentioned often interact with each other. Due to the high requirements, special materials with hardnesses of around 58 HRC are usually used. This poses the risk of cracks starting from the cooling channels due to the relatively low ductility of these materials. Such cracks usually inevitably lead to total failure of the tool. An efficient solution to this problem is tool segments coated using laser deposition welding for press hardening!

Andreas Bartling

Technical application consultant

Phone: +49 160-3889157

Downloads

Our solution

- Tailor-made hot work steel for the highest demands on tools that are actively cooled.

- Hardening of 56+2 HRC or 60±1 HRC (modified) in the active area

- Ductile, pre-tempered base material to reduce the tendency to crack starting from the cooling channel

- Coating height after deposition welding of 2.5±0.5 mm

- Effective layer height of 1.5mm after finishing

Your advantages

- Significant increase in tool life due to wear-resistant coating

- Lower tendency to crack starting from the cooling channel due to the high toughness of the base body

- Possibility of adjusting the local properties by adjusting the material, for example in the area of the active radius

- Reduced heat treatment effort through the use of pre-tempered base material

- Reduced repair effort and the possibility of reprocessing