Sustainable steel surface treatment

voestalpine is aware of its ecological responsibility and has set itself high goals in the area of sustainability. Carbon-neutral steel production by the year 2050 is our clear goal, and we already offer CO2-reduced steel in the greentec steel Edition. We already provide products that are convincing in many long-term applications without harming the environment.

Functional surfaces as an environmentally friendly steel treatment

All our surface treatments are free of chromium VI, chromium III and other hazardous substances. As a steelmaker, voestalpine is considered to be a pioneer in environmentally friendly production and coating processes.

Sustainable product benefits through functional surfaces

The versatile and sustainable surface treatments made by voestalpine improve the quality of the steel strip and provide additional benefits that result in cost savings and more efficient use of resources during further processing.

Certified, environmentally friendly functional surfaces for steel products

Our functional surface treatments are extremely versatile in their application and are environmentally compatible and efficient. Internationally recognized certifications confirm our path and obligation to sustainably develop our functional surfaces.

One step ahead with sustainable, functional surfaces

Actual properties often go far beyond the standard minimum requirements. All our surface treatments are chromium-free and set green standards.

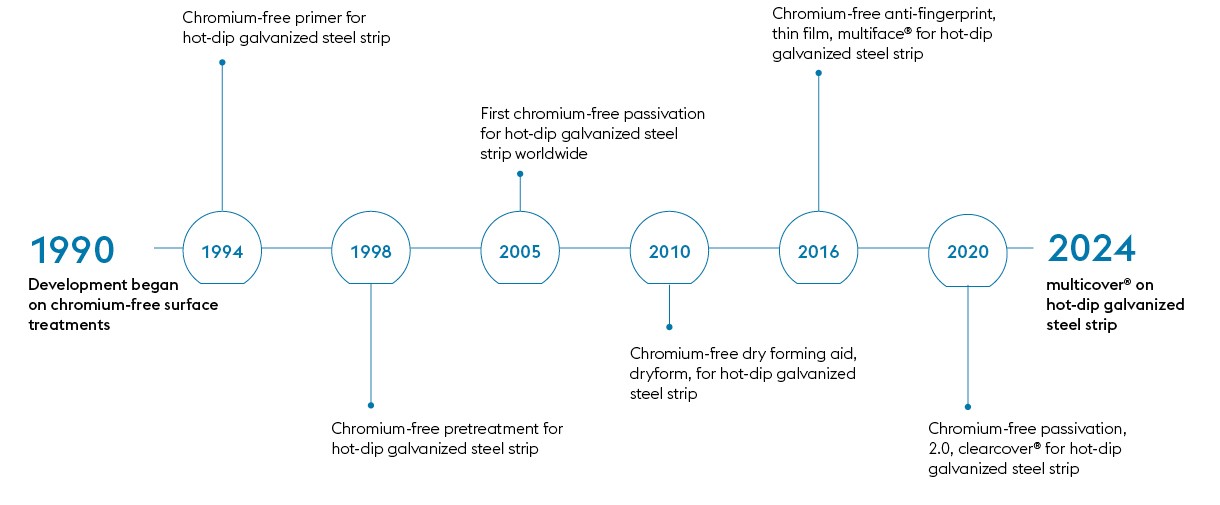

voestalpine – pioneer in the field of sustainable steel strip surfaces

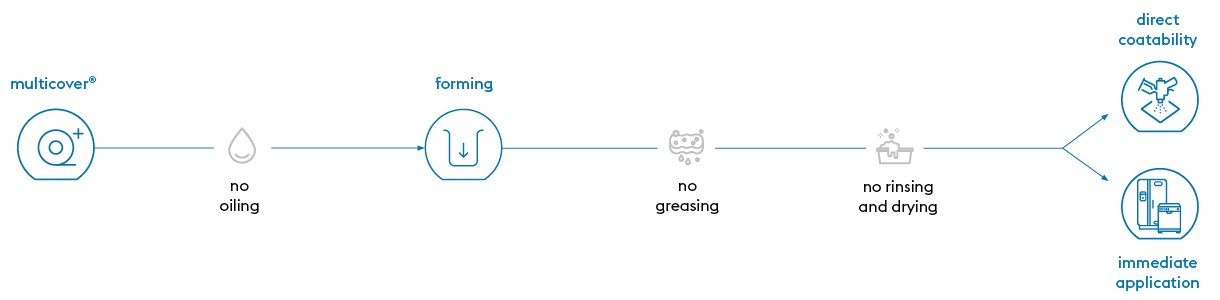

multicover® as sustainable, functional surface

Our functional surface multicover® provides significant advantages. Direct coatability in combination with oil-free formability is an enormous benefit. The possible elimination of energy- and resource-intensive process steps such as oiling, degreasing, rinsing and drying at the processing company reduces the ecological footprint and saves the substantial time and cost of pretreatment.

prelube2 as environmentally friendly forming oil

This functional surface reduces oil consumption and protects the environment for cleaner processing. prelube2 also helps to reduce friction during forming.

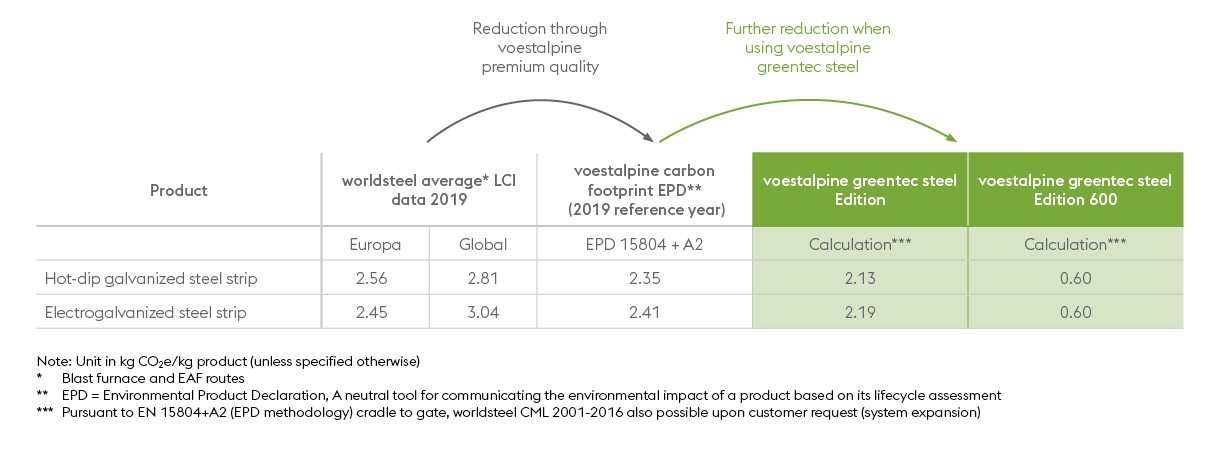

Sustainable steel for a better future

In addition to the fact that steel is 100% recyclable, the steel of voestalpine features low carbon footprints.

Already available today: Premium products in the greentec steel Edition

In order to reduce our footprint even further and as a first step toward climate neutrality, all our products are available in the greentec steel Edition. greentec steel is sustainable voestalpine premium quality with a reduced carbon footprint.

Read more about greentec steel, sustainability and our decarbonisation strategy on the website of Stella Sustainable, the ambassador for sustainability in the voestalpine Steel Division.