The sustainable and environmentally friendly passivation coating for galvanized steel strip

clearcover® is a sustainable passivation coating with outstanding corrosion protection properties and very good processing characteristics.

The surface treatment is the new, sustainable and environmentally friendly passivation coating without chromium or chromium compounds. The passivation is also free of other heavy metals. The less than one μm thick inorganic coating on galvanized steel strip provides good storage and corrosion protection during transport and supports formability and adhesive bondability.

A sustainable steel sealant available in different types

clearcover® ensures improved corrosion resistance, optimized bonding and paint adhesion and reduces the coefficient of friction during forming operations. The steel surface coating is available in two different types: available as clearcover® FVB for hot-dip galvanized steel strip and as clearcover® EVB for electrogalvanized steel strip.

Sustainable passivation for the elimination of time-consuming processes

Possible elimination of energy-intensive and resource-intensive processing steps such as oiling, degreasing, rinsing or drying results in a reduction of the ecological footprint and eliminates the need for costly and time-consuming pretreatments.

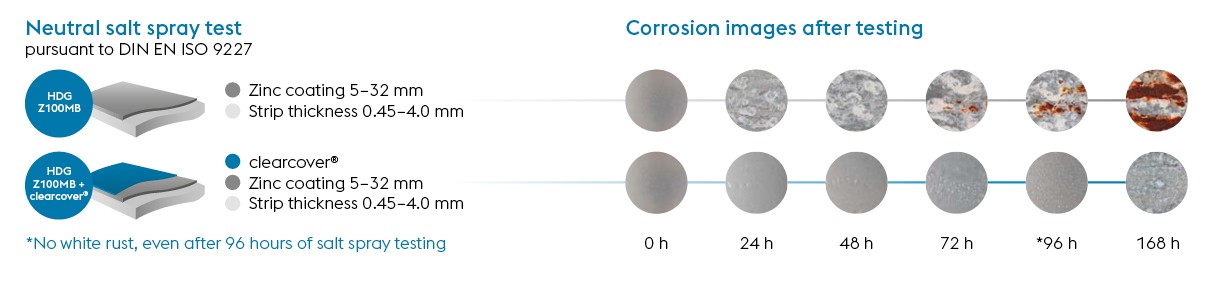

Maximum corrosion protection in galvanized steel products

clearcover® surfaces show a resistance to white rust after more than 96 hours of neutral salt spray testing pursuant to DIN EN ISO 9227 and over 50 cycles in alternating humidity and climate change testing (DIN EN ISO 6270-2 AHT). Setting new standards at voestalpine.

Quick and simple coating thanks to the direct coating process

clearcover® passivation can be applied directly as a powder coating or cathodic dip coating, even when cleaning processes have been eliminated. This eliminates degreasing or other pre-treatment processes and energy-intensive drying steps at the customer. The result is a high level of environmental compatibility with constant or improved performance in terms of paint adhesion and corrosion protection.

Typical applications

Industries that focus on functionality, quality and efficiency:

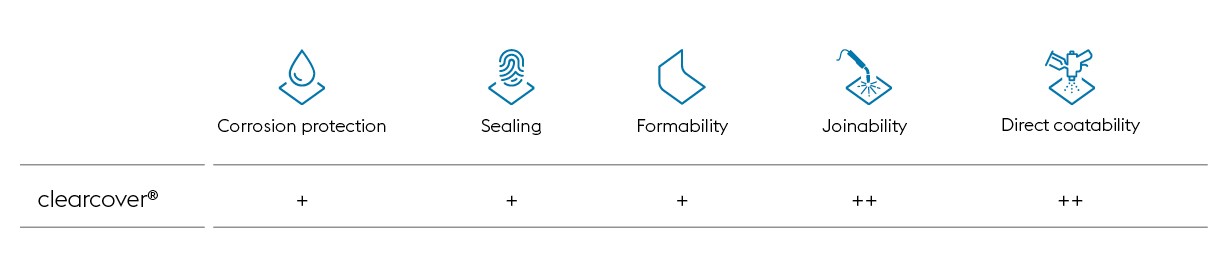

Properties at a glance

clearcover® is the future of passivation coatings on galvanized steel strip. clearcover is free of both chromium and heavy metals. The combination of corrosion protection, formability and direct coatability without time-consuming and cost-intensive postprocessing make clearcover® a sustainable passivation. Energy and other resources can be saved by reducing the number of processing steps.