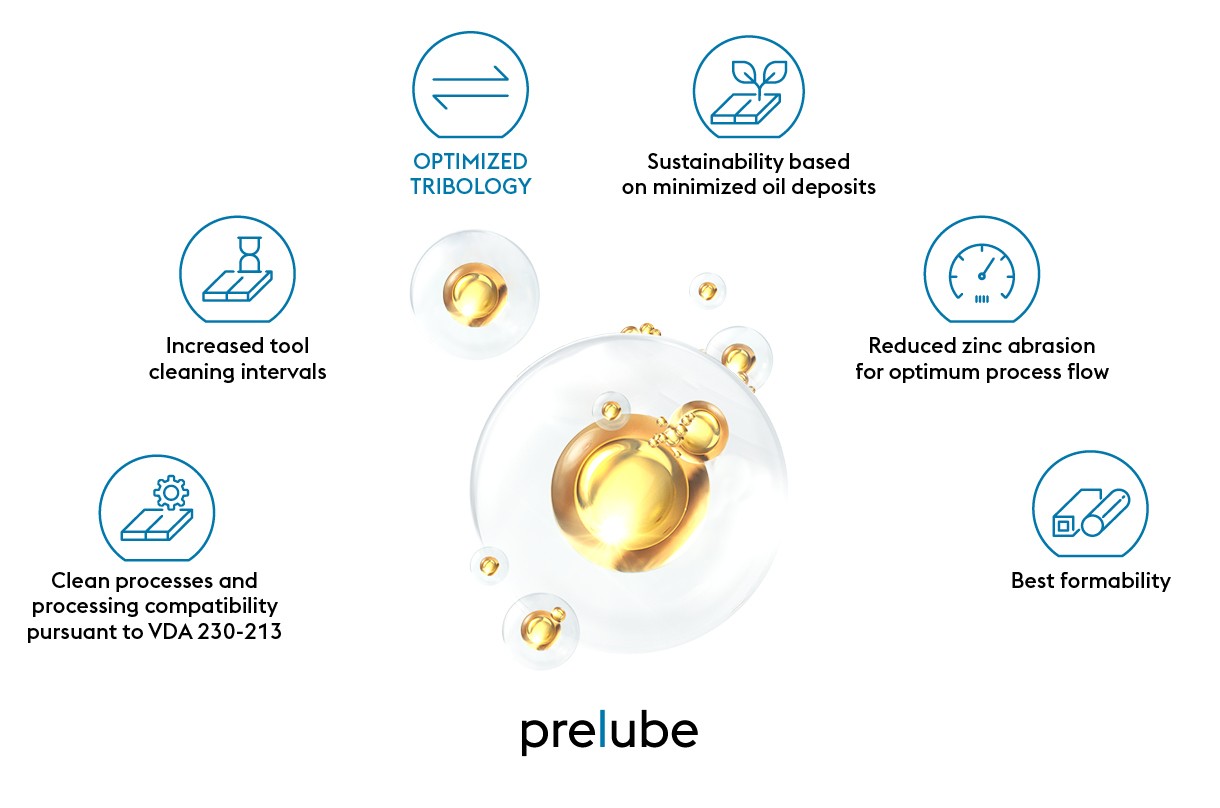

Optimized tribology and excellent oil distribution

prelube2 is a corrosion protection oil that increases cleanliness in production processes, enhances work safety, features improved tribology and is compatible with downstream processes.

The optimized tribology makes it possible to work with less oil on the surface while providing the same level of formability. This reduces oil leakage and redistribution on the steel strip during storage. prelube2 has the potential to reduce the friction coefficient, prolong intervals for tool cleaning and make production cleaner. prelube2 is highly suitable wherever the forming demands are the highest. Whether in the automotive or any other industry with high demands, prelube2 makes production even more efficient.

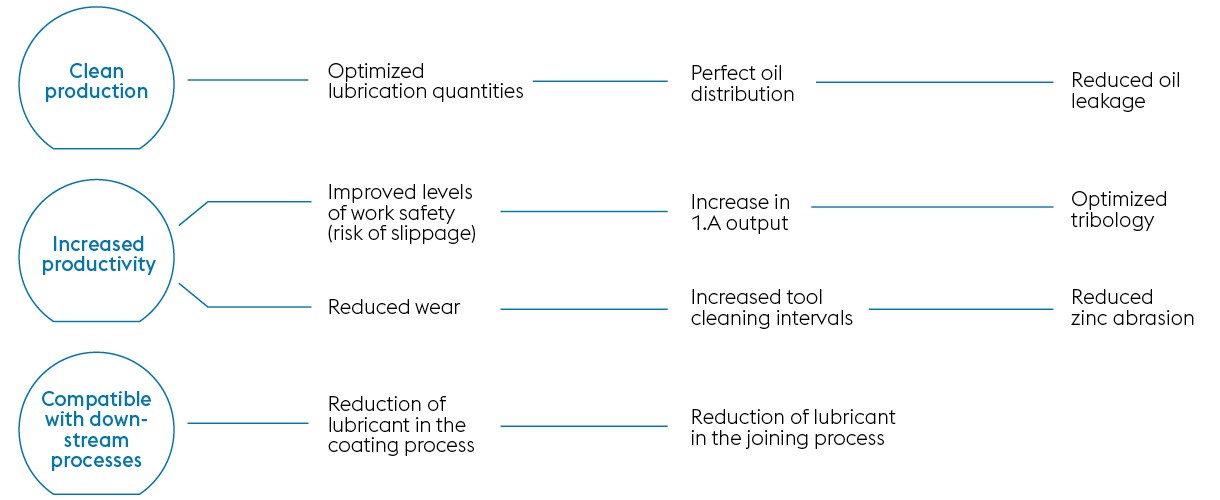

Processing benefits

The excellent tribological properties reduce the amount of lubrication required, thus enabling clean production processes (less oil leakage during storage and transport). This improves work safety and reduces the risk of slippage.

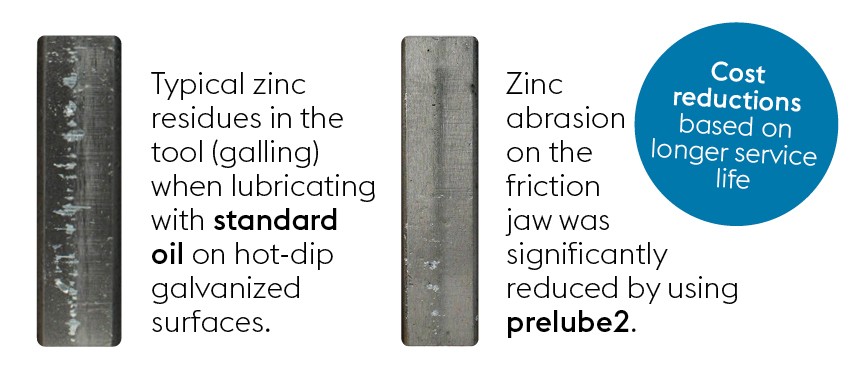

Significant advantages compared to standard oils

prelube2 (approved pursuant to VDA 230-213) reduces zinc abrasion in the forming tool for formed parts. The following figures show the results of the strip drawing test under the same conditions.

Sustainable and environmentally friendly forming oil for steel products

- The use of prelube2 reduces the oil coating layer thickness and protects the environment.

- The lower amount of surface oil conserves resources and enables cleaner processing.

- With the same oil layer thickness, prelube2 reduces friction during forming.

Typical areas of application

Properties at a glance

prelube2 is used for a cleaner production process and for a higher level of compatibility in downstream processes. An oil layer can be saved during forming, which is an essential aspect of this corrosion protection oil. Tool cleaning intervals are prolonged, and production runs more smoothly.