Tags:

TransANT GmbH is a joint venture founded in Austria in 2020. Today, the company is owned by voestalpine Stahl GmbH, the TAS Group and the ÖBB Rail Cargo Group. TransANT pursues the visionary idea of revolutionizing rail freight transport in Europe. Future-oriented, modular and customer-specific freight railcars are developed and produced.

Following initial development of the product portfolio, the receipt of government approvals and establishment of the company, TransANT GmbH is now ready for the production and delivery of freight railcars on an industrial scale. We have also gained a lot of initial experience: 30 TransANT BulkBox dual units have been in extremely successful use for voestalpine ore traffic since 2019.

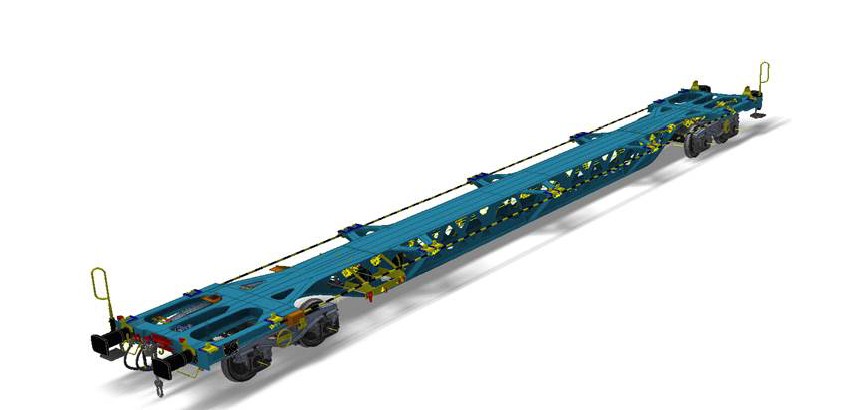

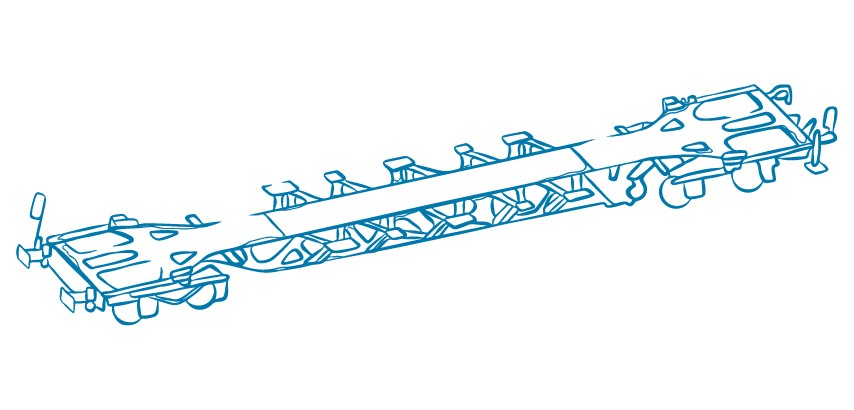

In the construction of the TransANT freight railcars, the company relies on high-strength alform® steel from voestalpine. TransANT engineers calculate the optimum topology of the railcars in order to ensure that the fine-grained structural steels in lightweight design can achieve their maximum effect. The result is by far the lightest platform railcars on the European market. More goods can be transported per load thanks to the weight savings and the load-optimized superstructures. This brings considerable advantages and ensures a clear conservation of resources. TransANT uses fewer trains for the same transport volume, resulting in lower energy costs and infrastructure usage charges.

More possibilities in freight logistics While conventional freight wagons cannot be adapted during their lifecycle of roughly 30 years, TransANT GmbH offers freight railcars in modular design. The modular freight railcar consists of a standardized platform in different lengths as well as an industry-specific and customized structure. If logistics requirements or transport volumes change over time, the body can be easily changed and the railcar can be used for other purposes.

The TransANT freight railcars are the first to use CO2-reduced steel for platforms and superstructures. The sustainable decision to use alform® steels in the greentec steel Edition saves CO2 without having to compromise on quality, processability and application properties. The value chain of the raw materials and goods transported with TransANT is significantly more sustainable from the outset than is customary in the industry.

TransANT GmbH is currently working on the introduction of further product lines based on high-strength steels in lightweight design. A wide variety of projects are currently being implemented by customers. Both development and production are in full swing.