Steel mills must adhere to strict maintenance schedules to avoid downtime of critical equipment in the production process. A prime example of this is Tata Steel, which has adopted an innovative maintenance approach that is aligned with market demands. This approach maximizes plant availability, equipment reliability and process and quality rates while minimizing labor costs, material costs and maintenance time over the entire life cycle of the equipment.

Make your repair work easier with UTP universal multi-layer solutions

UTP combines in-depth application expertise with the right choice of materials to be your reliable partner for repair of continuous casting rollers. Check out our universal multi-layer solution WEARcore 742 N-S and RECORD SK.

The importance of effective maintenance in steel mills

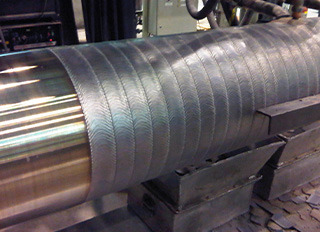

Repair of continuous casting line

The continuous casting line is a very critical part of the steel mill and its production. Throughout our many years of cooperation with the industry, we have developed the right products for every section of the continuous casting line to ensure the longest possible service life and surface quality of the equipment.

Introducing WEARcore 742 N-S / RECORD SK

Our WEARcore 742 N-S / RECORD SK system is the ideal choice, for steel mills seeking a universal multi-layer repair solution for rollers on the continuous casting line.

Why choose this solution?

- Universal Application: Designed for use across the entire casting line.

- Optimized Resistance: The submerged arc cored wire and flux overlay combination produces a martensitic microstructure. The balanced chemical elements deliver optimal resistance to common wear mechanisms.

- Efficiency: The product eliminates the need for multiple combinations, providing a streamlined repair process.

Recommended usage:

- A minimum of three layers is advised to achieve the desired weld composition and ensure superior performance in the top layer.

| C | Mn | Si | Cr | Ni | Mo | Nb | Fe | N | |

|---|---|---|---|---|---|---|---|---|---|

| All weld | 0.05 | 1.2 | 0.4 | 13.50 | 3.30 | 1.3 | 0.10 | Bal. | 0.1 |

WEARcore 742 N-S / RECORD SK - the entire typical chemical composition of the weld metal is to be achieved in three layers with a total thickness of 10-12 mm.

The combination WEARcore 742 N-S / RECORD SK features excellent weldability with flat beads with smooth overlaps and excellent slag removal. It offers the advantage of a repeatable, consistent repair process along the entire continuous casting line. The combi-nation has been successfully used by major steel works worldwide for many years, with expected life time of reclaimed rollers exceeding 3.5 million tons of production output.

To increase the deposition rate, use our alternative strip / flux combination SOUDOTAPE 430 / RECORD RT 742.

We asked Job de Vries and Henk Schipper from Tata Steel Ljmuiden what makes the work with UTP so special:

UTP has been our trusted partner for the repair of continuous casting rolls for 25 years. The team is familiar with the application and selects the right material for each section of our rollers. The benefits we have seen so far include improved performance of ourcasting rollers and significant reduction in the cost of repairs. The casting machine is a major challenge when it breaks down and production has to be stopped. This costs the steelworks € 65,000 / hour, which puts a lot of pressure on the production. When it comes to repairing our casting machines, we are very pleased to be able we to rely on our long-standing partner, who is always coming up with new ideas and trying to improve the service life of our components. Fifteen years ago, we started working together to develop WEARcore 742 N-SK with the flux RECORD-SK to improve the lifetime of our rollers. With success.

With UTP’s repair solutions, steel mills can maintain production excellence while reducing costs and downtime. Let us help you achieve your maintenance goals with confidence.