GREEN ELECTRICITY GOES UNDERGROUND

POWERING THE NEW ELECTRIC ARC FURNACE

The year 2027 will be electrifying! The construction of a new electric arc furnace (EAF) at voestalpine's Linz site marks a decisive and important step towards achieving our climate goals. A groundbreaking ceremony for another EAF has already taken place at the Donawitz site, too. Together, these new furnaces will save almost 4 million tons of CO2 per year. That's 5% of all CO2 emissions in Austria!

SUPPLY AND DEMAND

Of course, the EAF in Linz will need a supply of electricity.

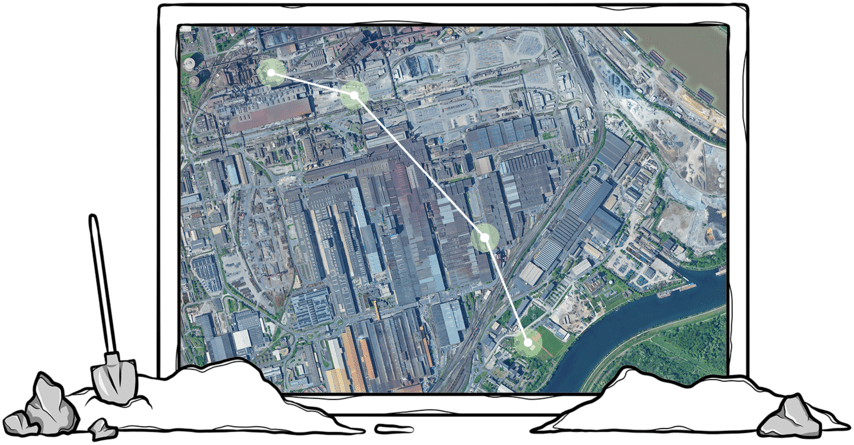

This energy is provided to us by Austrian Power Grid at the edge of our site, about 1,600 meters as the crow flies from the steelworks.

But how does the electricity get from there to the EAF? Initially, we considered above-ground power lines. But it soon became clear that an underground solution has many advantages. On the one hand, it allows us to work around the highly developed plant site, and on the other hand, overhead lines simply do not look particularly attractive.

STEP BY STEP TO THE SOLUTION

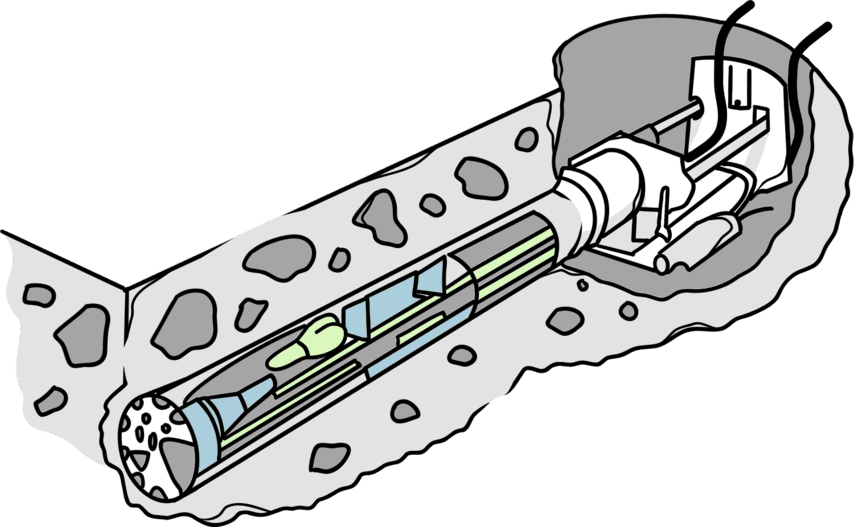

Space-saving and out of sight: microtunnels will transport the electricity where it needs to go. Microtunnels consist of vertical shafts that are connected underground by horizontal tunnels.

Scheduled to start in the second quarter of 2024, excavation work is required only for the construction of the shafts. Next, the tunnel sections will be drilled between the shafts. The tunnels and shafts will then be prepared for the cables, which will be laid in the final step. The cables will be water-cooled.

SUSTAINABLE STATS

The four shafts have an inner diameter of 12.4 meters, while the tunnels, which run at a depth of about 25 meters, have a diameter of only 2 meters.

Because the microtunnels can be built in almost a straight line, their total length will come to 1,700 meters – quite a savings over the estimated 4,000 m long above-ground version.

Microtunnels are an underground genius idea to supply energy to our future EAF.

Stella Sustainable, Sustainability Expert