Additive Manufacturing

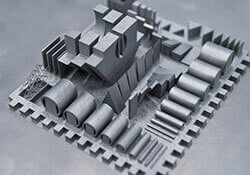

Additive Manufacturing (AM) is a term used to describe a suite of technologies that utilize a layer by layer approach to manufacturing parts. It is this technology that allows engineers to design complex near-net-shape components that would be too difficult or costly to produce using traditional subtractive manufacturing methods.

We see Additive Manufacturing as much more than just 3D printing. The successful implementation of the technology is dependent on a deep understanding of design, materials and the printing system to be used.

At voestalpine we ensure the highest possible quality, reliability and consistency by managing every step of the value chain from powder production to the delivery of the finished part.

AM Products and Services

AM solutions for industries

One-stop Shop for Additive Manufacturing Tailored Solutions

We aim to make the adoption of Additive Manufacturing as stress free as possible. Therefore, we offer our customers a simple consultation process that allows them to choose the level of engagement that’s right for them.

Whether it’s a single part order or series production, printing parts to customer supplied model data or supplying production ready tooling inserts.

We make AM simple.

| Powder Production |  | Metal Powder tailored to customer applications (BÖHLER, Uddeholm and other leading providers). |

| Parameter Development |  | We optimize the printing parameters to ensure the highest density component for your application. |

| Design & Simulation |  | Design expertise in Metal AM components for multiple industries such as Die Casting, Injection Molding, Oil and Gas and Aerospace. |

| Printing & Fabrication |  | Access to a variety of build technologies such as: direct metal laser sintering, direct metal deposition with equipment from leading manufacturers.Capability to print a variety of steels and super alloys.Different build volumes allow for efficient build of different sized parts, whether for rapid prototyping or serial production. |

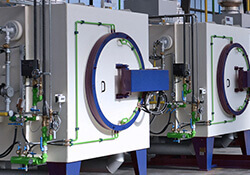

| Heat Treatment |  | Wide variety of Heat Treatment processes available for desired mechanical material properties, tailored for your application. |

| Machining |  | Access to the necessary final machining capabilities such as: turning, milling, grinding, polishing.Example of in-house capabilities: Nakamura-Tome NTRX-300L for fast, cost-efficient precision machining. |

| PVD Coatings |  | Achieve surface finish requirements with voestalpine eifeler Coatings’ latest PVD (physical vapor deposition) coating technology; designed to improve performance and tool life, allowing components to function in environments they otherwise may not be able to operate in. |

| Inspection & Testing |  | Inspection is done via laser 3D scanning allows the dimensional measurements to be visualized. For best accuracy, CMM inspection can be used.FARO ARMZEISS CONTURA 7 700 x 700 x 600 mm measurement envelope. Achievable accuracy: 1.5 + L/350 µm |

voestalpine is using its capabilities to further advance additive manufacturing and is establishing additional research centers and production facilities for this purpose. Specialists are constantly working on improvements to metal powders as well as on the design and production of metal components using the 3D printing process.

For more information on voestalpine Additive Manufacturing Solutions, please contact us.

Flexibility & Expertise

We draw our expertise across the voestalpine group. Beginning with our extensive knowledge in material development from BÖHLER and UDDEHOLM we combine design, simulation, 3D printing, heat treatment and coating experience, to ensure we can deliver complete solutions to our customers regardless of the project complexity.

Whether you have extensive 3D printing experience or looking at your first project, you can be confident we can support you.

Complexity & Efficiency

Our global network of voestalpine Additive Manufacturing Centres focus on two main powder based technologies Laser Beam Melting and Laser Metal Deposition. These complimentary applications can be deployed to manufacture complex components or re-manufacture / repair existing high value hardware.

Our experts can help our customers identify the suitable applications that will benefit from AM and which technology can be adopted to deliver the best results.

|  |

| Laser Beam Melting | Laser Metal Deposition |

Downloads

With Additive Manufacturing Center locations in Canada and the USA, we offer our customers end-to-end solutions across North America. Contact the location nearest you for more information.

Toronto, ON – Canada

Additive Manufacturing Center

T: +1 800-665-8335

Houston, TX – USA

Additive Manufacturing Center

T: +1 800-704-6866

June 2018: Building Confidence in Additive Manufacturing for Tooling

The start of any good product is the raw material, and that’s what Voestalpine is all about. Known in moldmaking circles for its Bohler and Uddeholm brands with their tool steel product lines, Voestalpine has also invested in the additive arena with its AM tooling powder development. However, using the right material for the application is just one part of successful additive manufacturing.

November 2018: Additive Manufacturing: Why the ‘concept to component’ approach is key for successful implementation

Additive manufacturing (AM) empowers innovative design with unprecedented benefits. With this rapidly advancing technology, it is crucial to integrate process disciplines and expertise to ensure an optimized product that achieves the desired quality and functionality while avoiding costly mistakes. In order to fully capitalize on AM’s potential, choose a provider that can link the full AM production chain together under one roof.

AM can offer tremendous opportunities for innovative design and productivity benefits. However, new technologies and innovations can also pose risks to those attempting to implement them. This article (vHPM Canada site) explores the major benefits and the inherent risks involved with this evolving value chain and suggests some best practices to help mitigate those risks.

A Global Network

Our global network of voestapline Additive Manufacturing Centres draw upon a wealth of expertise from across the voestalpine group. As a global market leader in the production of high performance steels, we are uniquely placed to service our customers metal based 3D printing needs.

Visit our global Centre of Excellence page for more details.

With Additive Manufacturing Center locations in Canada and the USA, we offer our customers end-to-end solutions across North America. Contact the location nearest you for more information.

Toronto, ON – Canada

Additive Manufacturing Center

T: +1 800-665-8335

Houston, TX – USA

Additive Manufacturing Center

T: +1 800-704-6866