Additive Manufacturing

Additive manufacturing is not simply a new way of producing. It’s a new way of thinking. There are no limits when a final product is designed and executed digitally – layer by layer. After digital design in a 3D CAD model, even the most complex structures can be “printed” layer by layer using metal powder.

We do not try to use AM for parts intended for other manufacturing technologies! AM is only economical if we add value to the part!

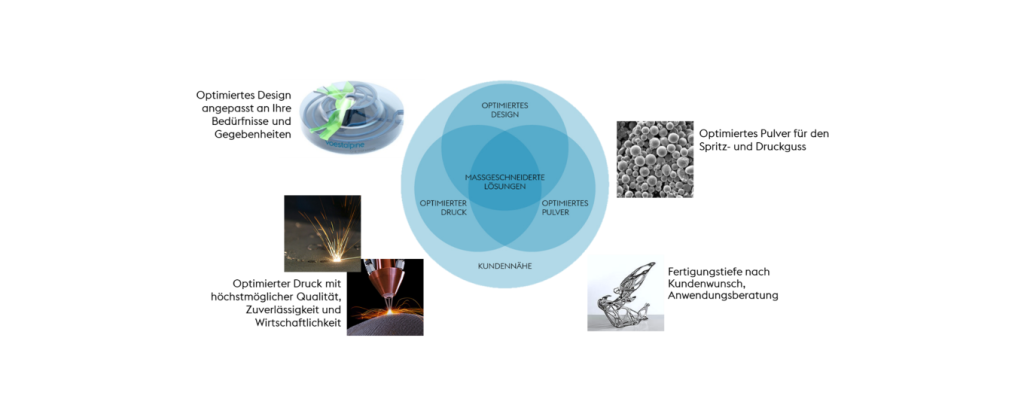

A COMPLETE SOLUTION

As a global technology leader and based on our many years of experience with materials and their processing, we offer a wide range of production technologies and services along the entire value chain that support innovations and drive developments forward. From the development of alloys and the production of metal powders to the design, simulation and manufacture of components and post-processing, we offer comprehensive solutions. This serves to minimize risk in the supply chain with the goal of being the reliable business partner you can trust.

TWO PROCESSES FOR A PERFECT SOLUTION

Powder Bed Fusion

Powder-based melting, also known as laser melting (SLM; PBF), uses thermal energy to selectively melt areas of a powder bed (according to ISO/ASTM DIS 52900:2018)

Material application with directed energy deposition – Direct Energy Deposition

Directional energy deposition, also known as laseer buildup welding, cladding, repair welding (LMD, DED, DMD), uses focused thermal energy (in this case, a laser) to fuse materials by melting during deposition (per ISO/ASTM DIS 52900:2018)

FLEXIBILITY AND COMPETENCE

Additive manufacturing centers use both laser melting and laser cladding. By working with both production technologies, voestalpine has the flexibility and expertise to select the additive manufacturing process best suited to your needs. Because tool steel is in our DNA.

IMPORTANCE

With the new design freedoms, the assembly of multiple parts can be eliminated and combined into one complex component. Additive manufacturing enables optimal manufacturing that leads to customized results in terms of weight and stability.

COMPLEXITY

Additive manufacturing offers a new way to produce complex shapes and structures, solving problems such as those encountered in injection molding processes. The tooling industry has great potential for additive manufacturing applications.

EFFICIENCY

Additive manufacturing shows up as an efficiency factor when parts are manufactured close to final dimensions.

Downloads

Contact

Anna Mad

Business Development Manager 3D Printing, Coating & Components

T +43 664 615 6016