Plastic Injection Molding

ADDITIVE MANUFACTURING – THE NEXT DIMENSION IN PLASTIC INJECTION MOLDING TOOLING

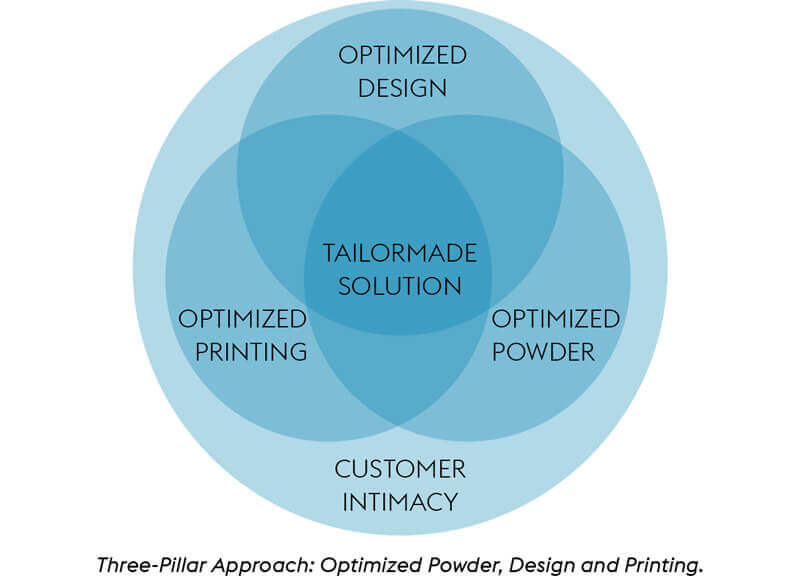

For decades we have been recognized as a global leader in the manufacture and the supply of tool steel, as a result we understand the challenges that our customers face in the PIM industry. Customer intimacy and technical understanding is a major factor when developing successful solutions with our partners.

Our attention to detail goes far beyond the design of the tool. Our additive manufacturing experts develop printing parameters specifically optimized to suit our range of high performance PIM materials, giving our customers unique solutions with superior results.

Unique tools require unique solutions. Working together with our customers, using our state-of-the-art additive manufacturing and materials know how, we develop tailormade AM solutions optimized specifically for PIM.

Your trusted AM partner

OPTIMIZED DESIGN

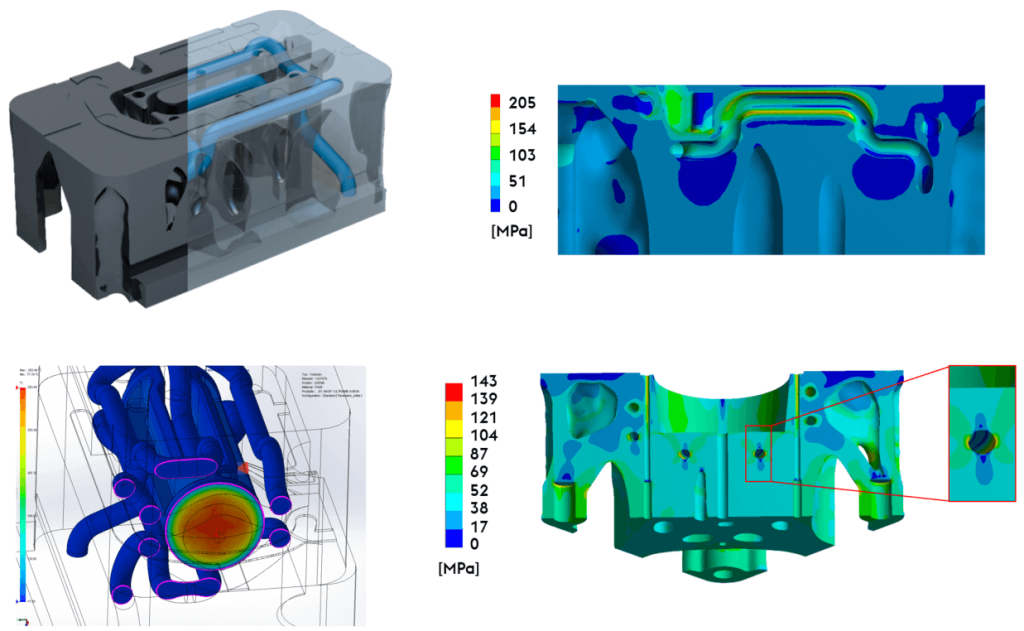

AM expertise paired with extensive PIM know-how ensures we deliver the best possible tooling solutions to our customers. We support our customers through a detailed consultation process to develop the right solution for the right application, using state-of-the-art tools to support the manufacturing process from initial concept to functional parts. Where needed our PIM experts can help our customers re-design tools according to the exact requirements of their application.

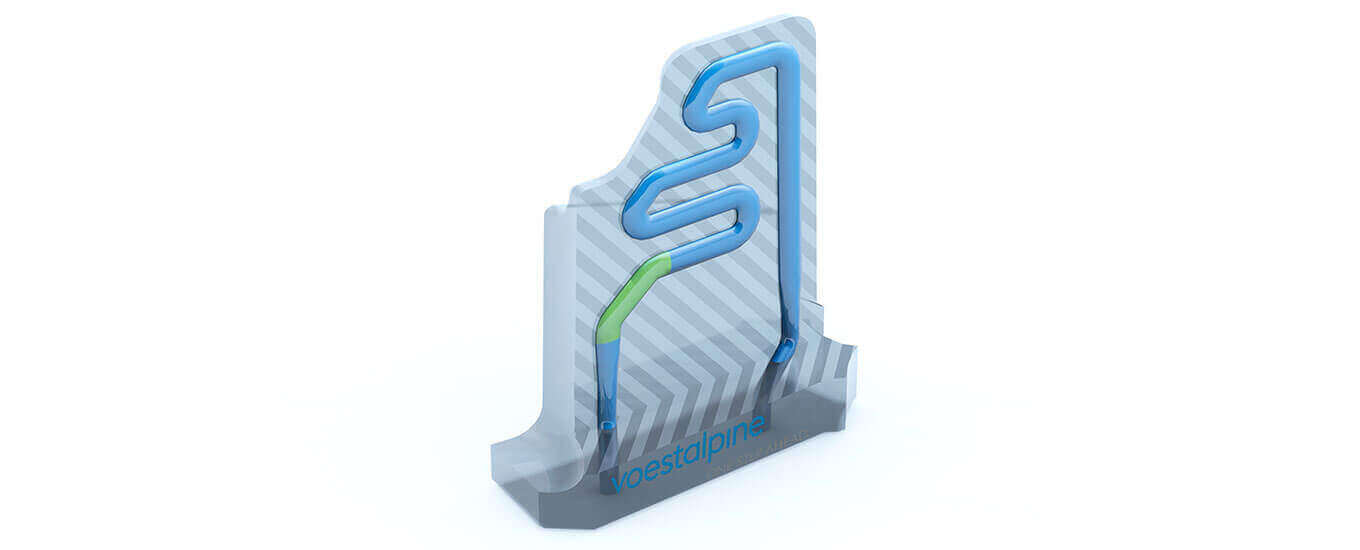

Our data driven approach to cooling channel design analyses processing parameters and mechanical loads to develop detailed computer models and process simulations. This method of optimizing thermal management is essential to ensure the right balance between efficient cooling and the mechanical performance of the tool.

This process goes far beyond regular conformal cooling channel design. We understand PIM.

Failure analysis and process simulation are important key competences. When paired with our AM design and processing know how, we gain a deep understanding of not only the challenges, but how we can best optimize the part in relation to the performance needs of the customer.

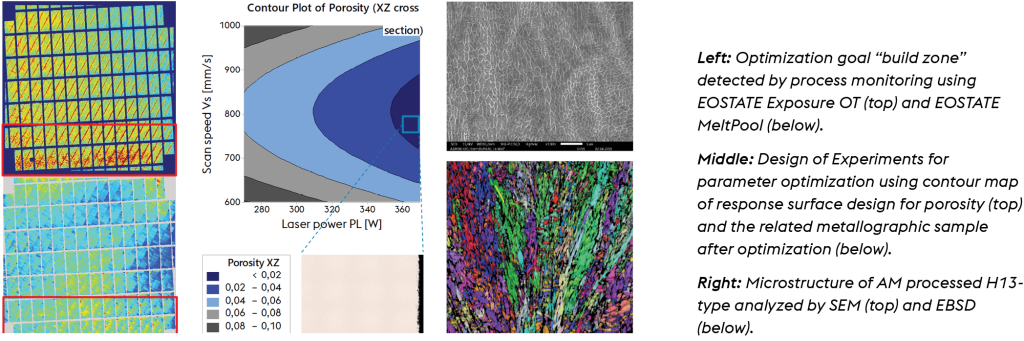

OPTIMIZED PRINTING

We ensure the highest possible quality, reliability and consistency by managing every step of the value chain from powder production to the delivery of the finished part. Whether for a single part order or series production, our internal quality systems ensure we meet your requirements every time. We use state-of-the-art tools to continually improve and refine our internal printing processes. Design of Experiments, Statistical Process Control, and Process Monitoring form the basis of our methodology. Continued innovation from our AM and materials groups ensures we deliver superior material properties in the most demanding applications with the best surface quality you can get with AM. As a result, our customers can put parts into service with the highest degree of confidence.

We understand the interactions between laser and material. This deep understanding of AM and PIM allows customers to add value to their business and realize competitive advantage.

OPTIMIZED POWDER

Our long history of developing materials for the PIM industry, means the powders we use are of the highest quality and deliver superior tool life.

Uddeholm Corrax for AM and BÖHLER M789 AMPO are our premium corrosion resistant grades, that had been designed to outperform the most common AM steel 1.2709.

IN SHORT

- Corrosion resistant

- Recommended hardness 45 to 52 HRC

- High toughness

- Designed for tooling applications, where corrosion resistance is needed

BÖHLER W360 AMPO is our premium grade with no corrosion resistance. This proprietary grade has been designed to outperform traditional tool steels such as 1.2343 ESR (H11) and 1.2344 ESR (H13)

IN SHORT

- Recommended hardness in use 50 – 57 HRC

- High toughness

- Designed for high demanding tooling applications like reinforced plastics

PRINTING & POST-PROCESSING

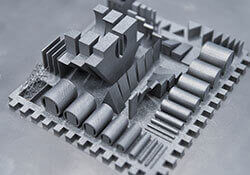

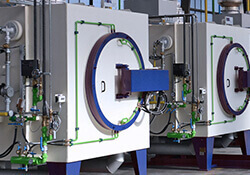

As a global steel and technology leader, we offer the full suite of production techniques and services throughout the value chain, supporting and driving innovation and development based on lengthy experience around materials and processing. Starting from the alloy development and metal powder production, to design and manufacturing and including post-processing. We offer the end-to-end solutions to reduce waste and mitigate risk in the supply chain with the goal of being your trusted and reliable business partner. We deliver tailormade solutions from concept to component.

Metal Powder

Parameter Development

Design/Simulation

Additive Manufacturing

Heat Treatment

Machining

PVD Coating

Inspection/Testing

PIM TAILORMADE SOLUTIONS

OPTIMIZED DESIGN. OPTIMIZED PRINTING. OPTIMIZED POWDER. OPTIMIZED FOR YOU.

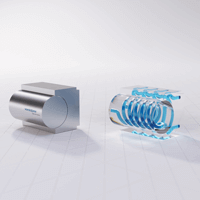

Our three-pillared approach to additive manufacturing has shown to deliver significant performance improvements to our PIM customers across a range of applications, such as inserts, sliders, filters and mixers.

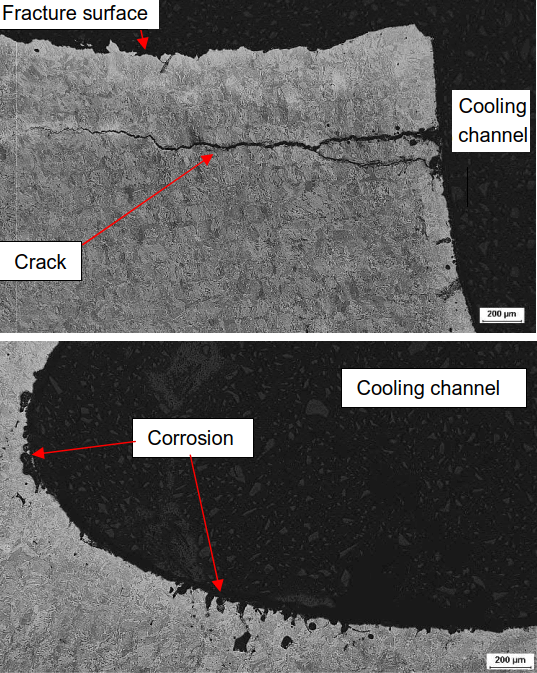

FAILURE ANALYSIS

Our support does not end with the delivery of additive manufactured inserts. It goes far beyond that. Every tool has a certain lifetime and fails at some point. We analyse and examine your failed tool inserts to determine the cause of damage. For example, a crack can have many different causes. Only those who know the cause can take the necessary action to extend the service life and to solve the problem.

Cracks caused by corrosion

Top: Fracture surface and further cracks (longitudinal view; image from light optical microscope)

Bottom: light microscope image of several corrosion spots in cross section

PLASTIC INJECTION MOLDING PRODUCTS

PIM BROCHURES

PIM CASE STUDIES

MATERIALS

FILTER & MIXXER

GENERAL RECOMMENDATIONS FOR ADDITIVE MANUFACTURED PIM TOOLING INSERTS

Follow voestalpine Additive Manufacturing on LinkedIn