Organic-coated steel strip that sets a green standard

voestalpine takes its ecological responsibility seriously and has always pursued a clear course toward sustainability for a better tomorrow. Our long-term goal is steel production with net-zero carbon emissions by 2050. We are actively committed to reducing the environmental impact of steel production with sustainable added value. For example, colofer® can boast of a sustainable manufacturing process as well as high resistance and long service life in the construction, home appliance and HVAC industries.

colofer® is fully certified and reflects our responsibility for human life and the environment

voestalpine Stahl GmbH in Linz, where colofer® is produced, complies with a comprehensive environmental management system pursuant to ISO 14001, has been certified by EMAS III (EG 1221/2009) and adheres to a set of 12 principles for socially and environmentally responsible steelmaking (Responsible Steel Certificate). In compliance with RoHS and REACH, colofer® meets the legal requirements of harmful substance safety.

colofer®, a solid foundation for the buildings of the future

Sustainable materials are indispensable in modern buildings, and corresponding certifications such as DGNB are becoming more and more important. colofer® is not a construction product in the sense of the Construction Products Regulation (EU) No. 305/2011, Article 2. Nevertheless, we supply an input material for your construction product in the interest of a successful DGNB listing with respect to a number of relevant criteria:

- Our externally verified Environmental Product Declaration (EPD) forms the basis for a robust lifecycle assessment (ENV1.1).

- Our products reduce the risk to local environments (ENV1.2) through consistent compliance with RoHS and REACH and through an extremely low concentration of volatile organic compounds (VOC).

- We ensure responsible resource extraction (ENV1.3) through comprehensive risk and supplier management that focuses on respect for human rights and fair working conditions along the entire supply chain.

- The advantages of colofer are particularly evident in the field of circular construction (TEC1.6) because voestalpine steel is 100% recyclable. A very high recycling content of 25% (verified by DEKRA) can be achieved in the LD steelmaking route. The service life of colofer® - up to 40 years - is also impressive, making it the ideal choice in future-oriented construction projects that combine sustainability, longevity and environmental responsibility.

Environmental Product Declaration (EPD) organic-coated steel strip PDF1.18 MBeng-GB

Environmentally compatible strip coating line

Each year, the colofer® strip coating line is among the best with respect to environmental parameters such as CO2 emissions, water treatment and energy consumption in the annual benchmarking analysis carried out by the European Coil Coating Association (roughly 90% of all companies in the industry and more than 50 strip coating lines are included in this survey).

More durable products with colofer®

You do not have to make any compromises with colofer® because you get first-class product performance AND optimal environmental protection. Numerous applications in RC 5 environments (coastal regions, industrial atmospheres) and warranties of up to 40 years prove our point: We offer today the solutions of tomorrow. This means sustainable resource conservation thanks to a significantly longer service life.

Made locally for a global market

Our steel strip and coatings from exclusively well-known European manufacturers form the foundation of the high quality and long service life of colofer®. Thanks to our integrated metallurgical facility in Linz, we can optimize every step of the production process with regard to sustainability, from the ore to the coatings to the finished product. With premium quality made in Austria, we not only use modern production facilities, but we are also close to our customers.

The ideas of today are the innovations of tomorrow

Our technical experts and researchers deal have developed even more sustainable solutions for the day after tomorrow. Here are some examples that will make our colofer® products even more sustainable:

- Organic-based coating systems reduce the proportion of fossil raw materials.

- Coating systems with lower enameling temperatures reduce energy consumption during production

- The use of recycled PET in coatings reduces the need for primary raw materials and the carbon footprint of the coating.

- Reduced hot laminating film thicknesses reduce material consumption by roughly 20%

Free from chromium and chromate for more than 25 years

We completely converted our colofer® production to an environmentally compatible technology with sustainable materials in 1998. Since this time, the production of colofer® has completely eliminated chromium and chromate, without compromising the excellent product performance and the length of warranties.

Sustainable steel with an impressively small footprint

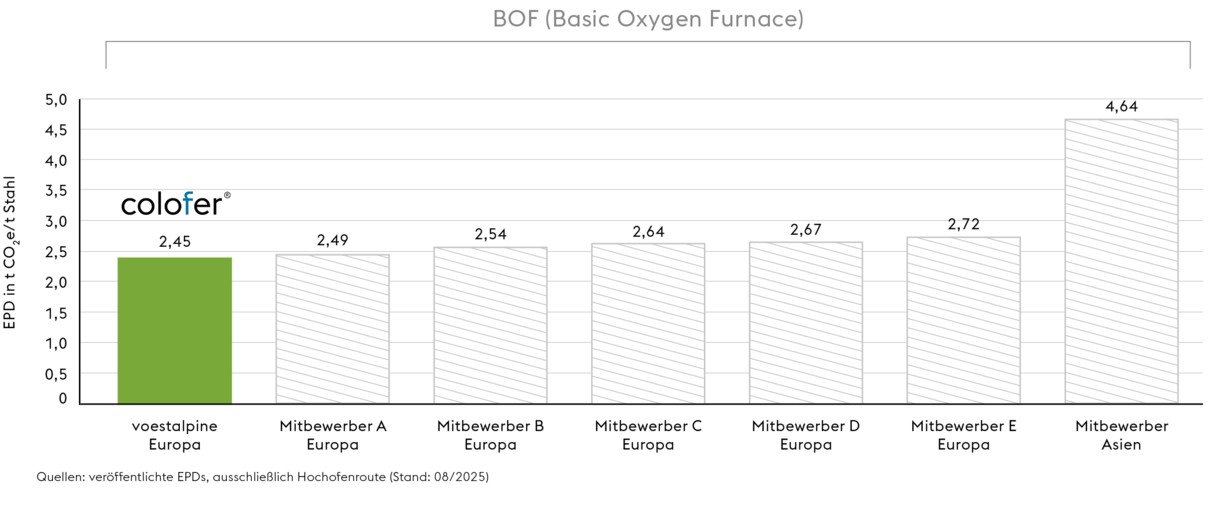

When compared with the global and European averages, the footprints of our conventional production process are the benchmark. This is even more evident when compared to published EPDs.

But it gets even better that that:

Our greentec steel Edition has made it possible for us to offer colofer® premium quality with a reduced carbon footprint since 2022.

greentec steel—our path to a green future

The greentec steel project of voestalpine is an ambitious step-by-step plan that makes a valuable contribution to the achievement of our climate goals. Please read more about greentec steel, our decarbonization strategy and sustainability on our Stella Sustainable page: