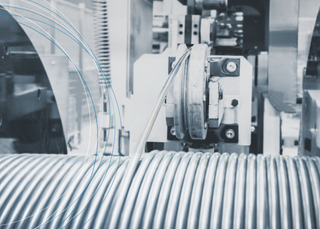

At voestalpine Wire Technology, we go from iron ore to finished wire product, ensuring exceptional quality and consistency. Our integrated production chain allows us to create perfectly tailored wire solutions for cold heading and cold extrusion, with dimensions ranging from 0.50 mm to 49.00 mm. We specialize in customer-focused, tailor-made cold heading wire, delivering high-quality materials that meet your specific requirements.

As a versatile and innovative partner with a unique research infrastructure, we ensure that each wire product performs in demanding applications and meets the highest quality standards. Our cold heading wire serves industries such as automotive, mechanical engineering, and metal construction, providing reliable solutions that enhance your production processes.

We operate based on the principles of quality, flexibility, innovation, and sustainability, which guide us through every step of production. These values form the foundation of our PERFORMANCE IN WIRE philosophy, driving continuous innovation and delivering wire solutions known for reliability, durability, and precision.

Whether for automotive components, mechanical parts, or other specialized applications, our cold heading wire delivers exceptional performance. By choosing voestalpine Wire Technology, you're partnering with a company that combines years of expertise, state-of-the-art technology, and a commitment to sustainability. Let us provide the wire solutions you need to stay ahead in your industry.