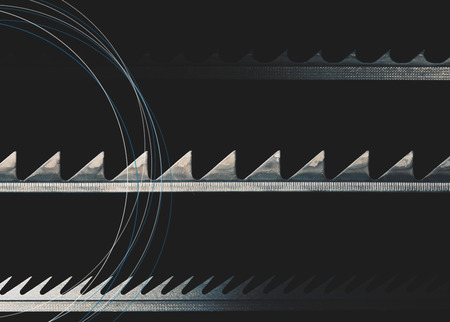

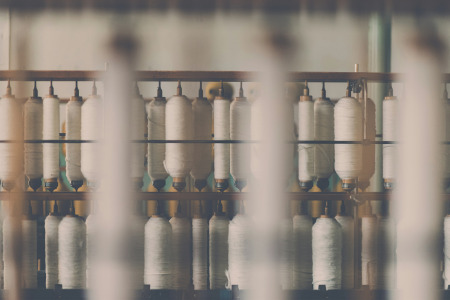

While many people think of wire products for the textile industry as simple clothes hangers, the applications here are far more complex. For decades, voestalpine Wire Technology has been a reliable supplier to Trützschler Card Clothing GmbH. Trützschler Card Clothing produces high-precision wires for carding and carding machines, which are essential for the production of yarns and nonwovens. These wires are formed into profiles with sometimes very fine serrations and wound onto rollers which, when installed in cards or carding machines, enable the carding process. These precision products are the result of years of development and perfected manufacturing processes.

High-precision wire products for the textile industry: innovations for the highest demands

Christian Steflitsch, Senior Sales Manager, and Johannes Gallobitsch, wire production expert, explain how voestalpine Wire Technology is making the textile industry more efficient. For more than two decades, the company has been supplying high-precision wires for cards and carding machines that meet the highest standards of quality and wear resistance. Cards are used in spinning preparation for cleaning and parallel alignment of raw fibers to form a fiber sliver. Carding cards perform a similar task in the production of nonwovens. Find out how these advanced wire solutions not only revolutionize textile production, but also increase efficiency and reduce the CO2 footprint through innovative manufacturing processes.

More than just wires: a surprising solution

What particularly distinguishes this product is the exceptional precision and uniformity of the toothing in the card as well as the consistent product quality. These properties ensure that the carding machines can perform their task reliably. Thanks to its excellent wear properties and precise processing, this product offers a decisive advantage over other solutions on the market.

From wire rod to premium product - challenges and innovative solutions

The manufacture of this clothing requires an extreme depth of production. The starting point is the wire rod, which is annealed and drawn several times to achieve the desired properties. This complex process ensures that the end product meets the highest requirements.

One of the biggest challenges in the production of these wires was the wear and tear that the manufacturers had to contend with.

To meet this challenge, new steel grades have been developed and the production processes optimized. Micro-alloys have helped to increase the hardness of the tooth tips and thus significantly improve wear resistance. In addition, process optimization and modernization of the production facilities have reduced both costs and CO2 emissions.

Advantages for the textile industry: sustainability and adaptability

The new solution offers customers in the textile industry significant advantages. The wire products developed are used worldwide, including in Germany and India. The project thrives on close cooperation with customers and the commitment of an experienced team, including Johannes Gallobitsch, who has been an expert in this field for 20 years. This close cooperation and the positive feedback from customers continue to drive motivation and encourage the company in its work.

We are working together with our customers on modified alloys to counteract the changed conditions in textile processing, e.g. through the increased use of man-made fibers and increased wear, and thus improve the service life of these products.

Trützschler Card Clothing GmbH in Neubulach, as part of the Trützschler Group, is the world market leader in the manufacture of high-performance card clothing for cards and carding machines used in the international textile machinery industry. More than 350 employees work in the Card Clothing division of the Trützschler Group worldwide, 170 of them in Germany. Further information: www.truetzschler-cardclothing.de

WHERE PREMIUM QUALITY MEETS ECO-FRIENDLY EXCELLENCE 2027

Develop with us, test with us, increase your cost efficiency and reduce your carbon footprint - thanks to premium wire solutions that enable fewer process steps and optimized processing times. From 2027, our greentec steel will set new standards. Join us on this journey and let us develop customized solutions for you together.