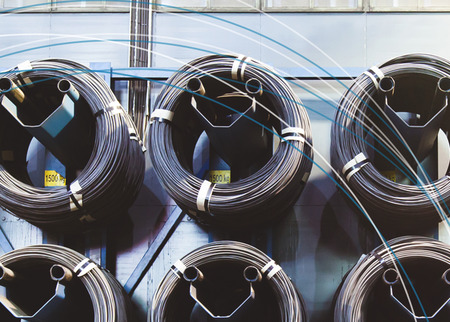

We offer variable delivery forms for wire rod up to 3 tons, whereby the binding is made with steel strip. It is possible for our customers to combine 2 x 1.5 ton coils into a 3 ton coil. Alternative delivery forms such as 2.5 ton or 2.7 ton coils are available on request.

Flexible logistics: wire rod in 3 ton format

voestalpine Wire Technology produces quality wire rod in the modern wire rolling mill of voestalpine Wire Rod Austria in St. Peter/Freienstein. Customers have the option of receiving deliveries in the format of 3 tons of coils or alternative delivery forms such as 2.5 or 2.7 tons of coils by prior arrangement. Convince yourself of the many advantages that the undivided 3 ton coils offer you.

Advantages of the 3 ton coils

The advantages of an undivided 3 ton coil over a 2 x 1.5 ton delivery form are numerous:

- Increased efficiency when loading the system: systems only need to be reloaded less frequently with 3 tons instead of 1.5 tons

- Waste reduction: Less binding material is required, helping to protect the environment

- Minimized risk of damage: Simplified handling and transportation due to increased coil stability

- Identical dimensions to the 2 x 1.5 ton delivery form

Customer requirements:

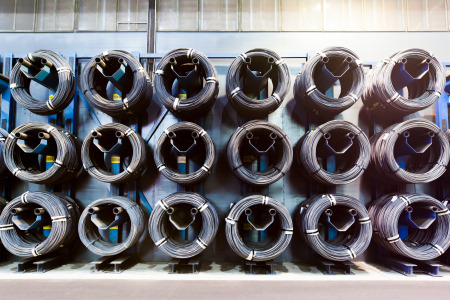

Customers using 3 ton coils will need appropriately designed infrastructure and lifting equipment, such as forklifts and cranes, as well as appropriate equipment such as reels, to handle and process these 3 ton coils.

Products, areas of application and quality assurance

Our wire rod is characterized by excellent mechanical-technological properties and enables the best formability through thermomechanical rolling over the entire dimensional range.

Thanks to our integrated production chain, we guarantee continuous quality control and seamless traceability of all production and testing parameters throughout the entire process, from the steel to the finished ring. This ensures consistent product quality that is tailored to the specific requirements of our customers.

We supply wire rod for the production of cold heading and cold extrusion steel products, bearing steel products, springs, saw wire, welding wire products and chains. We also offer specialized steel grades such as AFP steels, dual-phase steels and micro-alloyed wire rod.

Our commitment to environmental protection is reflected in the development of prototype wagons for the environmentally friendly transport of wire rod coils, optimized by lightweight construction for better utilization and gentler transport of the wires. Within Austria, we already rely 100% on "green" transportation.

PERFORMANCE IN FLEXIBILITY. Our value chain begins with our own ore, continues in the steelworks, rolling mill and drawing mills and, if required, extends beyond our customers' factory gates. We therefore offer maximum flexibility in all process steps, customized solutions for surface treatment, packaging and transport - and of course just-in-time - in the consignment warehouse, with batch sizes of up to 3 tons.

Our quality wire rod products

With PERFORMANCE IN WIRE, we guarantee the highest quality, the tightest tolerances and maximum flexibility, while our customers also benefit from our materials expertise and know-how. At the same time, we stand for high-quality further processing within our broad product range: wire rod for cold heading & cold extrusion steel products, roller bearing steel products, springs, saw wire, welding consumables, chains