Thanks to the CC4 continuous casting plant, voestalpine Wire Technology, in close cooperation with voestalpine Stahl Donawitz and voestalpine Rail Technology, has now been able to obtain certification for its continuous cast wire products after an approval process lasting several years.

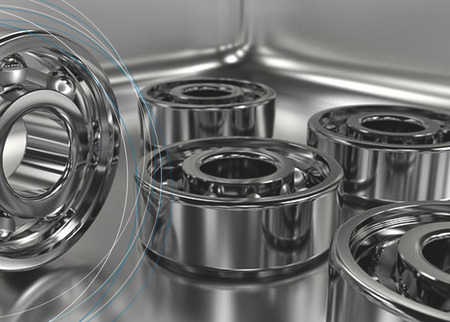

100Cr6. The premium variant of steel grade 100Cr6 is used for this. During the customer's production process, a small piece of the wire is sheared off, which is then upset, heat-treated, ground, and polished to obtain the round shape. The initial certification was preceded by a long process of technical and commercial exchange. voestalpine Wire Technology developed the suitable material in close internal coordination. Whether the further processing into balls would be successful was only revealed during extensive testing of the balls by the customer and the ball bearings fitted with them. Following successful testing, the approval applies to all types of ball bearings.

This opens many possibilities, as ball bearings are used, for example, in bicycles, cars, trains and industrial machinery as well as in automation.