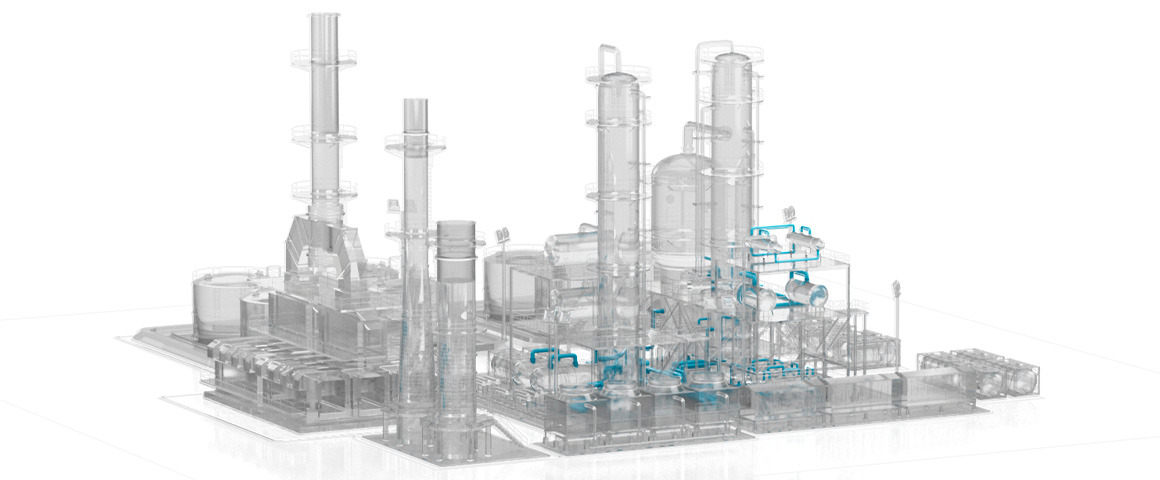

Tubes & Pipes for Pressure Applications

Our tubes and pipes for pressure applications ensure safety and efficiency in refineries, power plants and the chemical and petrochemical industries. They are ideal for heat exchangers, waste heat recovery and industrial high-pressure systems.