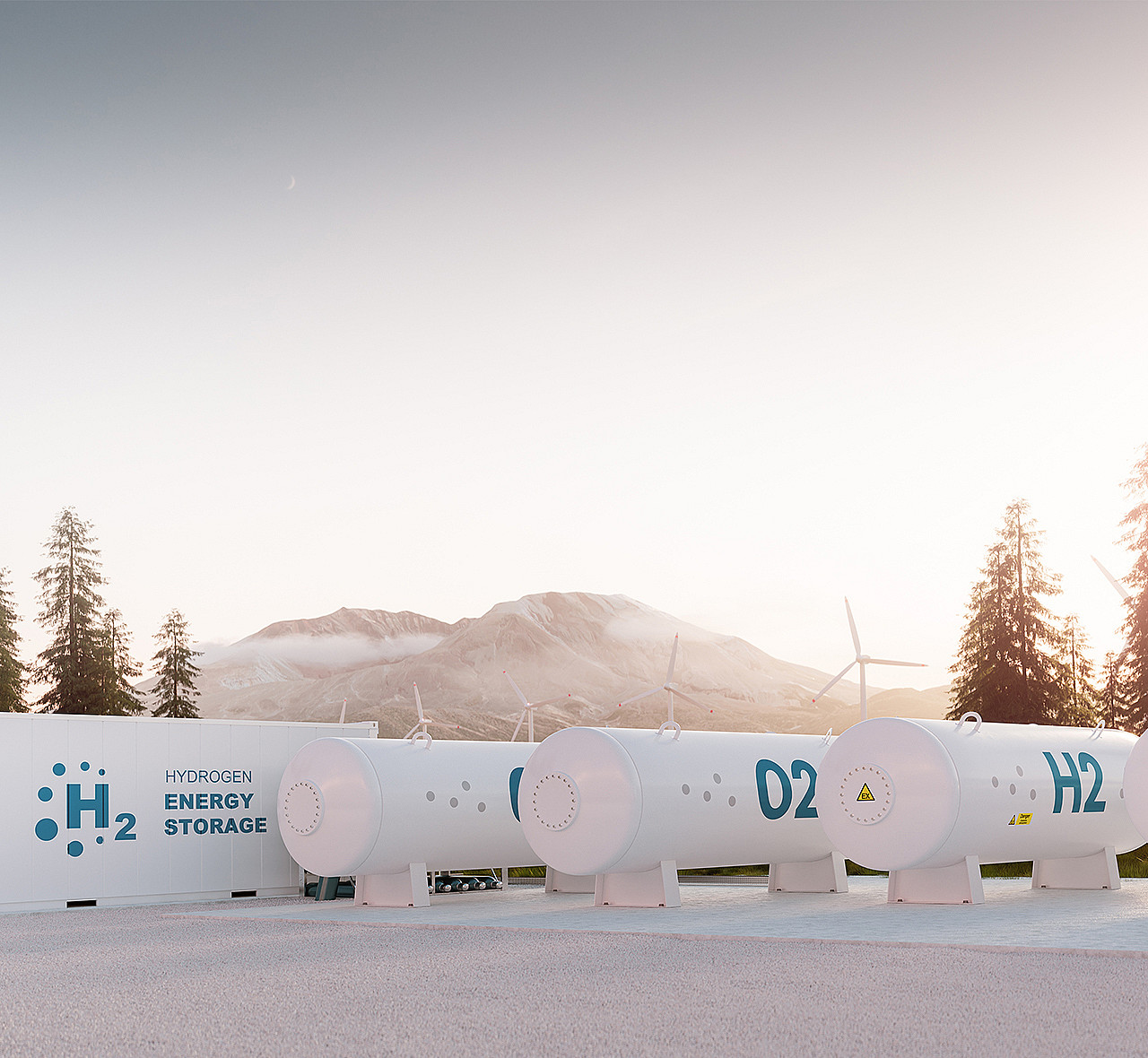

Hydrogen applications

Explore our customized solutions especially tested for hydrogen application!

voestalpine Tubulars has the essential know-how in steel and tube production, the long-term experience in connection development and manufacturing for the oil and gas industry as well as the testing capabilities to design the optimal product solutions – all these parameters are prerequisite for safe use of hydrogen too.

Therefore, the company already offers the following product solutions, which are already successfully installed in several hydrogen storage and line pipe projects.

voestalpine Tubulars has the essential know-how in steel and tube production, the long-term experience in connection development and manufacturing for the oil and gas industry as well as the testing capabilities to design the optimal product solutions – all these parameters are prerequisite for safe use of hydrogen too.

Therefore, the company already offers the following product solutions, which are already successfully installed in several hydrogen storage and line pipe projects.

VAhyper®

Tailor-made casing & tubing grades

Tailor-made Line Pipe grades for distribution lines

Additional products and solutions available upon request.