Product Form

We are a partner for every step in the oil & gas industry value chain with an extensive product portfolio.

Machined parts

- With core competences in metal processing and stock-keeping we act as material manager for specialty metals

We are a reliable supplier of a broad range of high-end solutions around nickel and titanium alloys as well as materials with specific physical and technological properties. Our profound engineering experience ensures a reliable supply of machined parts for oil and gas application.

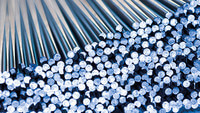

Bars & Billets

- Count on reliable and consistently high quality

Quality knows no compromise. We deliver materials of highest metallurgical purity for use in the most extreme environments. We are one of very few suppliers worldwide having all kinds of melting and remelting plants at our disposal (ESR, PESR, VAR).

With decades of industry experience and a focus on creating solutions using cutting-edge technologies (melting & remelting, rolling & forging, heat treatment, machining and testing), we are a leading specialist for low-alloyed, medium-alloyed, and high-alloyed special steels, as well as nickel-based alloys. We excel in the development of customized solutions. The features of our products, such as tight tolerances or extremely small machining allowances, are impressive, innovative, and specialized.

We deliver billets in accordance with international quality standards in a broad range of steel grades and nickel alloys. On request, we also melt metals beyond the standard grades to individual specifications.

Open & Closed Die Forgings

- Trust in competence from the melt to the finished product

We are your partner when high mechanical stress has to be considered and highest reliability under aggressive environmental or ambient conditions is demanded. From steel production to forged product completion, we preform every step in the production process at our own plants. We take responsibility into our own hands, and we ensure that our customers get end-to-end quality assurance. We check and document the quality of our products at every point in the production chain.

Our open die forgings are characterized by the tightest tolerances and big dimensions. In our state-of-the-art plants, we produce drawingbased forgings weighing up to 40 tons. We have many areas of expertise, including the production of impellers, disks, and shafts for compressors or gas turbines; tubing and casing hangers for wellheads; and components for Christmas trees, separators, pumps and valves in rough-machined condition.

Precision and ruggedness, as demanded, for example, in the case of drill bits or gas lift mandrels, characterize our closed die forgings. The products we develop together with our customers have proven successful under the toughest operating conditions, and they are excellently reputed all over the world.

Sheets & Plates

- Count on the optimum material for each and every application

Special tasks demand special solutions. We provide a broad range of special sheets and plates. The applications of our sheets and plates may vary, but they have one thing in common: they are all customized solutions for heaviest duties.

Tube & Piping

- Count on outstanding technical knowledge and commitment to providing excellent service

Wire, Round & Flat

- Count on the optimum material for each and every application

We combine experience with quality production and leading know-how, making us a specialist in the manufacturing of shaped wire. We provide customized solutions and set industry trends, offering a broad portfolio of standard wires with high economic efficiency. The top quality we deliver is based on the integrated production chain from our own steel mill to our state-of-the-art rolling mills, which ensure the tightest possible tolerances. Long-standing customer partnerships, customer-oriented research & development, simulation activities, and customized heat and surface treatment, as well as logistic solutions testify to our competence and expertise. We are a dedicated partner, and we are committed to fulfilling special requirements and creating solutions for specific applications.