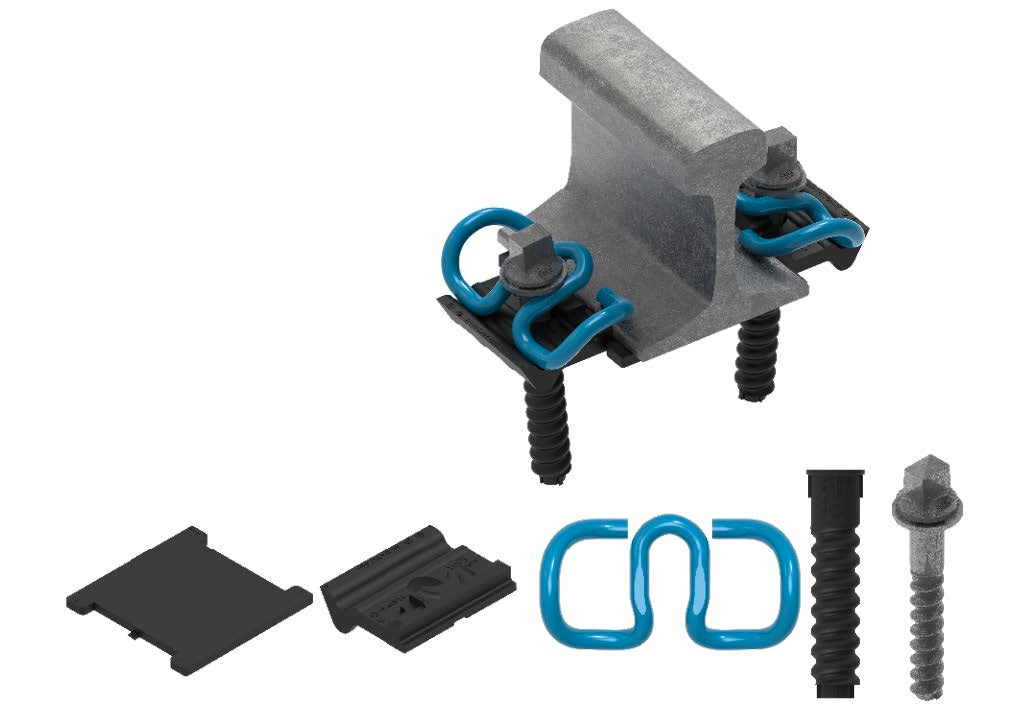

W21 NT rail fastening system

Introducing the W21 NT Type rail fastening system, meticulously engineered to meet category C and D specifications in accordance with the EN 13481-2 standard, boasting a maximum permissible axle load of 260kN and a minimum curve radius of 150 meters.