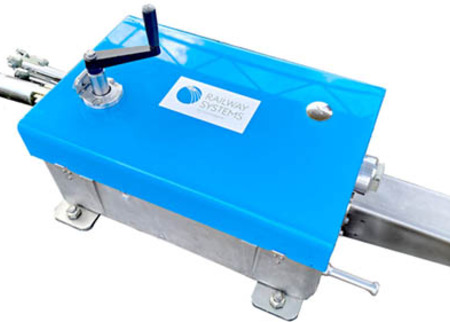

ECOSTAR 5.0

The compact electro-hydraulic point machine with external lock.

The compact electro-hydraulic point machine with external lock.

ECOSTAR 5.0 is a point machine of the latest generation. It can be used regardless of the interlocking technology and is basically compatible with all standard interlocking systems.

The compact point machine system with external locking system, e.g. SPHEROLOCK® NG, offers simple configuration options for setting and impact forces. Conversion from „non-trailable“ to „trailable“ design while installed in track is possible by simply exchanging modules. The interchangeability of the modular system components optimises the repair time.

The low weight enables easy installation and handling. Its slim design makes it perfect for tunnel applications and retrofitting or modernising existing point machines.

Maximum safety, reliability and availability, even under adverse environmental conditions.

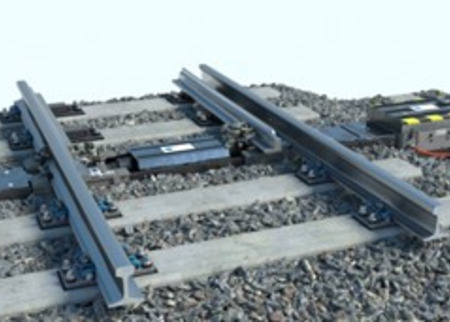

Redefined performance. With its powerful electro-hydraulic drive, ECOSTAR 5.0 is able to guarantee a smooth movement of switch rails as well as movable point frogs. Depending on the type, the point machine can be designed as a trailable or non-trailable version. An innovative and slim-fit construction design allows installation in hollow steel sleepers, enabling fully automated tamping.

Due to its independence of the interlocking system and the possibility of manual operation, the point machine is ideally suited for retrofitting or modernizing existing switching machines in the track. The point machine ECOSTAR 5.0 can be combined with a wide variety of locking systems, end position detectors and force transmission systems and, in combination with other Signaling components, results in a perfectly aligned setting system.

Digital monitoring enables railway companies to make immediate availability statements without employees having to enter the track. This eliminates the need for significant interventions in railway traffic without a veri-

fiable reason: Less disruption to operations, higher availability of the track system, greater cost-effectiveness and targeted availability of spare parts on the track. The railway track is less impaired and is therefore available for longer for economic operation.

| Feature | Value / Type |

| Turnout type | Vignol |

| Minimum gauge of the turnout (mm) | independant |

| Throw range (mm) | 110 to 240 |

| Main dimensions (LxWxH, mm) | 1315x466x294 |

| Overall mass (kg) | 115, without connecting parts |

| Temperature range | -40 °C to +80°C |

| Protection class | IP67, according to EN 60529 |

| Fixation to track | 110V to 400V AC Stock Rail Fixation / Sleeper Fixation with bearers |

| Housing material | Aluminium |

| Locking system | external locking device |

| Max. number of possible locking and setting units | Single- and multiple Setting Levels possible |

| Max. Throw force | 2 - 9 kN |

| Power supply | 12V - 400V AC/ DC |

| Trailing speed | from 2 - 8 sec. (depending on power) electro-hydraulic; from 0,8 - 7 sec. electro-mechanic |