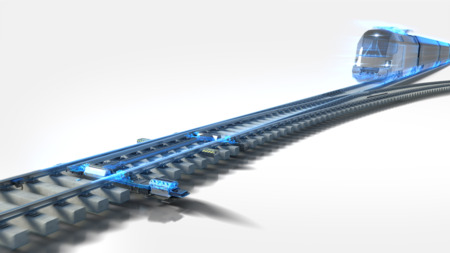

Key challenges in mixed rail traffic

- Increased train frequencies

- Faster traveling speeds

- New drive systems

- Higher axle loads.

Our solutions meet these challenges with robust tracks, low-noise designs, and environmentally sustainable manufacturing to ensure reliable and economical railway systems.

The supplier counts. Robust tracks, high comfort levels, as little noise as possible and an environmentally compatible approach calls for modern, sustainable manufacturing processes on the part of suppliers. Innovative and intelligent products designed with a provider's expertise are also in demand where integrated system and service solutions are concerned.

A functioning transport network thanks to outstanding technologies. We offer innovative and intelligent products combined with groundbreaking concepts. We apply them to improve service life, availability, reliability and ease of maintenance for rails, turnouts and signaling technology - in addition to monitoring and diagnostic processes on all continents.

Overall solutions from a single source. As a pioneer in economical (LCC) and technical (RAMS) product optimization, we combine cutting-edge technology with systems expertise right down the line. At around 60 sites globally, we bundle our knowledge and supply our local customers with products and services tailored to their needs whilst offering benefit. We stand for maximum efficiency overall solutions – helping customers get ahead in terms of technology and competition.

Rail technology: Optimized rail track for mixed traffic with our 400 UHC® HSH®

Extreme track loads. Railroad rails are one of the steel products subjects to the greatest stress. Network operators all over the world are faced with daily challenges such as rail wear, crack formation and other damage to rails occurring during operation.

Damage limitation. Whatever the problem: All damage means significantly impaired track performance and can be eliminated only with major financial expense and at the cost of reduced system availability. voestalpine confronts this fact with the world's largest portfolio of heat-treated, high-performance grades which have been developed on the back of years of experience.

The high-grade pearlitic steel 400 UHC® HSH® (conforming to Euronorm R400HT) combines this technology with an innovative materials concept. It is able to reduce track damage by a factor of six in comparison with standard grades (R260), and by a factor of two compared with heat-treated rails in the conventional performance category (R350HT).

Ecological and economical. The “green” low alloy concept (non-alloy rail steel) ensures first-rate weldability. Where economics are concerned, the resistance to all types of rail damage – previously unknown in the mixed traffic sector – offers major track optimization potential: it can save an entire investment cycle.

Key Benefits:

- Maximum resistance to rolling contact fatigue, wear and corrugation

- Maximized operational availability with minimum life-cycle costs

- Simple to weld thanks to the innovative materials concept of a non-alloy pearlitic rail steel

- Noise attenuation effect through minimized corrugation

- Customized application recommendations via our interactive rail LCC tool, including a comparison with different investment and maintenance strategies („path-to-optimum“ access)

- Years of outstanding experience with the standard application

Why choose 400 UHC® HSH® rails:

This innovative steel grade optimizes track performance and extends lifecycle investments, offering unmatched value to mixed traffic systems.

Learn more about 400 UHC® HSH® Rails.

Turnout systems: Engineered for versatile mixed traffic demands

Fit for the wind and the weather. Whether facing snow or ice, desert sands or extreme temperatures – the railway network has to be safe and sustainable as well as economical and comfortable at the same time, functioning properly in all corners of the world. We have therefore made it our objective to optimize this system.

Innovation for the railways. We use smart and innovative products and services to deliver solutions fit for the future: besides classical switch products for all rail sections and gauges, we manufacture special track components such as rail expansion and insulating joints or transition rails.

Innovative turnout products and system solutions for maximum requirements:

Our solutions for growing demands include automated and self-adjusting systems and checks. This allows us to improve the availability and service life of rail track, something set to play an increasingly important role in the mixed traffic sector in the next years:

|

|

Key Benefits:

- Systems expertise and responsibility (integrated safety assessments/verifications)

- Tailor-made solutions for all customer requirements (innovative, environmentally friendly and economical)

- Combination of global experience (under different environment/load conditions) from the boundary of the high speed and heavy haul sector for optimization in mixed traffic

- The only manufacturer with an integrated rail basis and comprehensive expertise in rail track

- In-depth knowledge of manganese casting

- Life-cycle costs (LCC) and availability-optimized products

- CO2-optimized manufacturing processes

- Large in-house fleet of tilted-load freight cars for delivery of turnouts / pre-assembled ready for laying

- Global cooperation with Getzner Werkstoffe for optimization of elasticity levels in the track (innovative, high-quality components for under sleeper pads, rail/base-plate pads, etc.)

Global Expertise:

We leverage knowledge from high-speed and heavy-haul rail sectors to optimize performance in mixed traffic. Our cooperation with Getzner Werkstoffe enhances track elasticity with innovative under sleeper pads and rail base-plate pads.

Explore Intelligent Turnout Solutions for Mixed Traffic.

zentrak: Your intelligent ecosystem for Mixed Traffic

Increasing train frequencies, higher speeds and growing axle loads place significant demands on your mixed-traffic routes. To ensure smooth operations, it is crucial to minimize unplanned downtime and optimize availability and safety. This is where zentrak comes in!

zentrak provides continuous monitoring of railway infrastructure and rolling stock, offering a comprehensive 360° view of all critical components. By intelligently linking and analyzing data, zentrak enables a predictive maintenance strategy, allowing you to detect and address emerging issues before they lead to disruptions.

Rely on zentrak to enhance the performance and safety of your network – ensuring seamless and efficient operations of rail transport infrastructure.

Learn more about zentrak solutions: