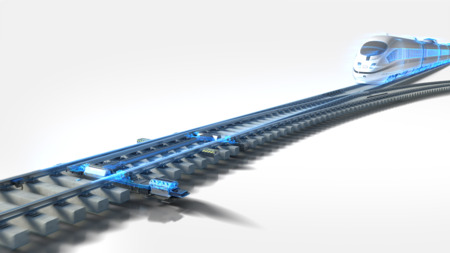

Smart rail quality for the highest speed

The lifeblood of the big city. A fast, environmentally friendly and comfortable journey between cities – that is both the wish and need of many people all over the world. Travelling by train is becoming more attractive in relation to air travel, above all on medium length journeys, thanks to higher speeds and increasing frequencies.

High speeds – high demands. Stringent demands are however being made on modern rail infrastructure. This is due to not only speeds up to 350 km/h and over, but also the complex interaction between substructure, superstructure and vehicle. Attention thus focuses on issues such as safety and availability as well as fast maintenance options.

Groundbreaking technology. We offer innovative, cutting-edge products with the expertise of a provider as well as trendsetting concepts. We thus improve service life, availability, reliability and ease of maintenance for rails, turnouts and signaling technology on all continents – and under all climatic conditions.

Overall solutions from a single source. As a pioneer in the consideration of economic (LCC) and technical (RAMS) optimization potential, we bring together innovative technology with systems expertise right down the line. voestalpine Railway Systems stands for overall solutions with maximum efficiency – so helping customers get ahead in terms of technology and competition.

Rail technology: Heat-treated high-performance rails for high speed rail traffic

Speeding ahead on the right track. There is hardly a high speed network in Europe without rails from voestalpine. For example, the world‘s longest railway tunnel, the Gotthard Base Tunnel with a length of 57 km, is equipped with our 120 meters rails and our high-speed switches. The 50 km Eurotunnel, linking France with Great Britain, was also supplied with heat-treated rails from voestalpine.

Patented rail technology for the high speed rail infrastructure. Thanks to their resistant, fine pearlitic microstructure, heat-treated rail steel grades are ideal when it comes to combating damage mechanisms occurring in curves on high-speed routes. The globally patented HSH® heat treatment technology provides the rail head with maximum resistance to rolling contact fatigue while also maximizing endurance in the rail foot. Additionally, the non-alloy steel design of HSH® rails allows for optimum weldability. There are no limits to the range of applications. Manufactured in lengths up to 120 m, HSH® rail steel qualities are available in almost 100 different sections.

Added value:

- High resistance to rolling contact fatigue (RCF)

- High straightness and flatness over the entire life cycle (resistance to wear)

- Excellent weldability

- Significant reduction in rail maintenance costs

- Marked increase in service life in the track

- Clear drop in life cycle costs

High speed turnout systems: Modern turnout technology for fastest railroads

Fast connections between cities and optimum links to public transport mean that modern high speed trains are a serious alternative to air travel and private transport. Given the growing environmental awareness and the trend in energy prices, today‘s high speed technology offers huge potential. Speeds of almost 400 km/h and diverging speeds exceeding 200 km/h make stringent demands, but can be mastered safely and comfortably today thanks to state-of-the-art turnout technology. High speed turnouts are specialized for maximum requirements.

Innovative products and system solutions for the high speed rail system:

- High speed turnout systems

- Optimized switch devices (FAKOP: Kinematic Gauge Optimization)

- Movable point frogs in customized versions

- Highly elastic base-plate / fastening systems

- Rail expansion joints, including for extreme expansion lengths

- Concrete sleepers

- Extensive service package

Added value:

- System expertise and responsibility - everything from a single source

- Comprehensive international references and experience

- In-house rail production enables global product optimization

- Experience with all track systems (slab track, etc.), e.g. high speed rail tracks

- Innovative switch blade geometries for reduced wear and greater ride comfort

- Optimized component design (reduced pickup jolt, lower lateral acceleration)

- Elasticity adjustable thanks to highly elastic fastening systems

zentrak: Your intelligent ecosystem for High Speed Traffic

High speeds and dense train frequencies put extreme demands on your high-speed rail network. Maximum availability and predictive maintenance are essential for seamless operations. This is where zentrak comes in!

With continuous monitoring of railway infrastructure and rolling stock, zentrak provides a comprehensive 360° view of all critical components in your high-speed network. By intelligently connecting and analyzing the collected data, wear and potential disruptions can be detected early, allowing maintenance measures to be initiated at the optimal time.

Rely on zentrak to keep your high-speed rail network safe, reliable and efficient – delivering peak performance at maximum speed.

Learn more about zentrak solutions:

How can we help you?

If you have questions or feedback, please feel free to contact us. We are happy to help!