Freight and heavy haul transport

Growing demand and extreme conditions - hard labor for the track. Freight and heavy haul transport are increasingly shifting to the railways. This is due to the ever-increasing demand for energy and raw materials combined with growing global awareness of safety and the environment. Even customers whose core business often lies outside railway infrastructure find themselves confronted with the associated challenges. It is necessary to cater for ever-greater capacities and axle loads. Extreme weather and environmental conditions such as snow or ice, desert sands or temperature fluctuations have to be mastered, as well as long distances. Resistance is in required.

Fierce competition. In a fiercely competitive sector, there is a need for innovative, tailor-made freight rail system solutions if customers are to be guaranteed safety, economic efficiency and availability. We develop individual concepts that cater for the needs and circumstances of each customer to optimum effect.

Low maintenance and high economy. Our systems, which are life cycle costs (LCC) optimized, guarantee maximum service life and efficiency with long maintenance intervals. Maintenance of our rails, turnouts and signaling technology is also simple, along with the monitoring/diagnostic processes in the heavy haul sector. As a pioneer in economical (LCC) and technical (RAMS) product optimization, we combine cutting-edge technology with systems expertise right down the line.

Rail technology: Heat-treated super premium rail quality for freight traffic: 400 UHC® HSH® Product line

Weather and the environment. Premium quality, from the desert to the polar tundra. Top performance not only under extreme environmental conditions, but also in regions with aggressive wear – e.g. sand in wheel-track contact: 400 UHC® HSH® Product line.

Our expertise - your safety. This fine pearlitic rail quality is manufactured according to a special metallurgical principle (Super Premium concept) and is also standardized as R400 HT in the EN13674 norm.

Use of the globally patented HSH® heat treatment technology not only provides maximum resistance in wheel-track contact, but at the same time extreme endurance in web and foot.

Manufactured in lengths of up to 120 meters, these rails are available in all sections satisfying a huge range of standards and specifications:

- 400 UHC® XR HSH®: the robust, high-end rail for outstanding performance and efficiency in the track - our recommendation for heavy haul applications.

Other grades:

- 400 UHC® HSH®: the classical solution for rail freight requirements.

- 400 UHC® CS HSH®: the CS series encompasses individual solutions, adapted to specific customer needs.

- 400 UHC® P HSH®: upgraded performance with increased resistance for heavy haul applications.

Added value:

- Maximum resistance to rolling contact fatigue

- Maximum resistance to wear and rail corrugation

- First-rate weldability thanks to non-alloy steel design

- Clear reduction in rail maintenance effort due to outstanding track performance

- Significant increase in service life in the track compared with common high-strength steel grades

- Maximum availability with minimum life cycle costs

Turnout systems: Strong turnout system solutions for freight traffic

Great pressure on turnouts. Freight and heavy haul rail transport or railways involves extreme technical requirements in relation to load and resistance levels. Our turnout systems guarantee maximum safety, economic efficiency and availability – including with very high load values.

Our experience, your benefit. We support our customers in a fiercely competitive sector, offering them our expertise and services to give them a decisive infrastructure advantage, leaving them free to fully focus on their core business.

Innovative products and system solutions for maximum requirements:

- System turnouts

- Switch devices with optimized geometries and rail materials

- Movable point frogs

- Manganese frogs, weldable (explosion-strengthened)

- Diamond crossings

- Spring frogs

- Base-plate systems

- Sleepers (concrete, wood, composite, steel)

- Fastening solutions

- Extensive service package

Added value:

- Robust and economical customer system solutions – LCC-optimized

- Lower maintenance costs/longer service life

- Maximized track availability

- Materials and geometries optimized to requirements

- Extensive global applications experience with virtually all conditions of use

- Automatic tamping due to use of hollow steel bearers or drives on sleepers

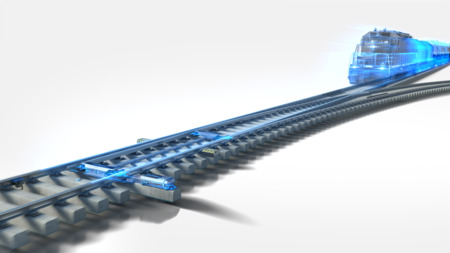

zentrak: Your intelligent ecosystem for Heavy Haul

Freight rail faces major challenges, including extreme weather conditions such as snow, ice and desert sand, as well as intense competition. To ensure cost-effective and reliable operations, high asset availability and predictive maintenance are essential. This is where zentrak comes in!

With continuous monitoring of railway infrastructure and rolling stock, zentrak provides a comprehensive view of all critical components in your freight network. By intelligently linking and analyzing collected data, zentrak enables early detection of wear and potential damage, allowing maintenance activities to be planned and implemented proactively.

Rely on zentrak to make your freight corridors more resilient, reliable and efficient—ensuring seamless operations for heavy haul transport.

Learn more about zentrak solutions:

How can we help you?

If you have questions or feedback, please feel free to contact us. We are happy to help!