Technology -

Made in United States

The engineering staff of voestalpine Precision Strip WI in our site in Wisconsin has a combined more than 60 years of experience in the special niche of the precision strip steel industry, especially in the field of hardened and tempered products.

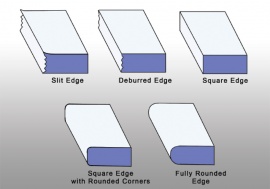

Steel Edge

Conditioning

/ Skiving

voestalpine Precision Strip WI in Pleasant Priarie performs edge conditioning through a high-speed edging process known as skiving - the successive removal of material from the edge in a series of carbide dies - resulting in a smooth "machined" edge. Skiving can be performed on one of three individual lines resulting in the ability to skive a wide range of strip dimensions and a variety of edge configurations.

The process of skiving, or machining the edge has distinct advantages over edge rolling which is a deformation and hence stress-inducing process. An additional advantage with respect to a "stress-free" edge is the fact that we edges the vast majority of its strip prior to the hardening and tempering process. This so called single-strand-hardening process results not only in a stress-free edge but also has significant positive impact on resultant strip shape (camber / twist / coil set) properties.

Following edge configurations are in standard availabale:

The process of skiving, or machining the edge has distinct advantages over edge rolling which is a deformation and hence stress-inducing process. An additional advantage with respect to a "stress-free" edge is the fact that we edges the vast majority of its strip prior to the hardening and tempering process. This so called single-strand-hardening process results not only in a stress-free edge but also has significant positive impact on resultant strip shape (camber / twist / coil set) properties.

Following edge configurations are in standard availabale:

- Slit edge

- Deburred edge

- Square edge

- Square edge with round corners

- Fully rounded edge