Precision and quality united: endurance hollow sections

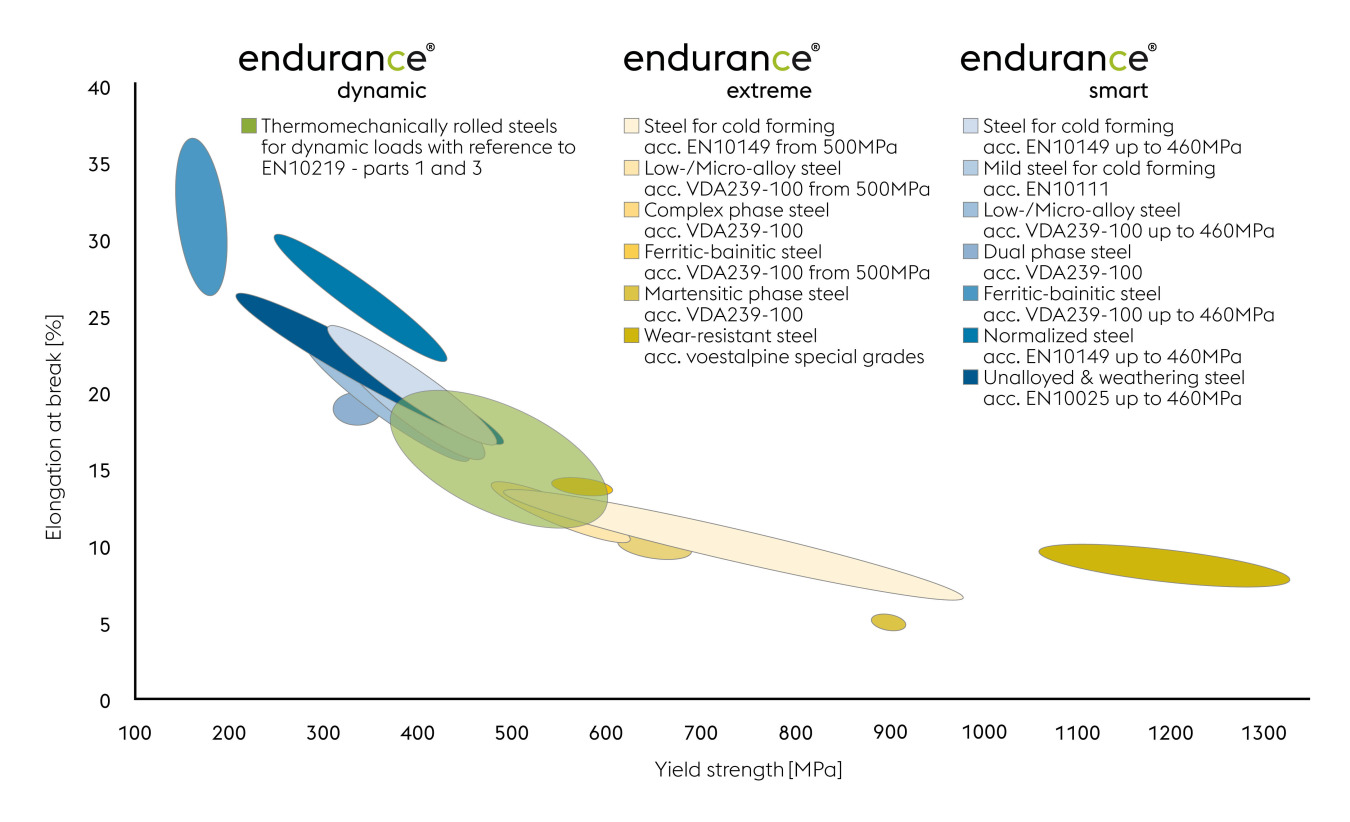

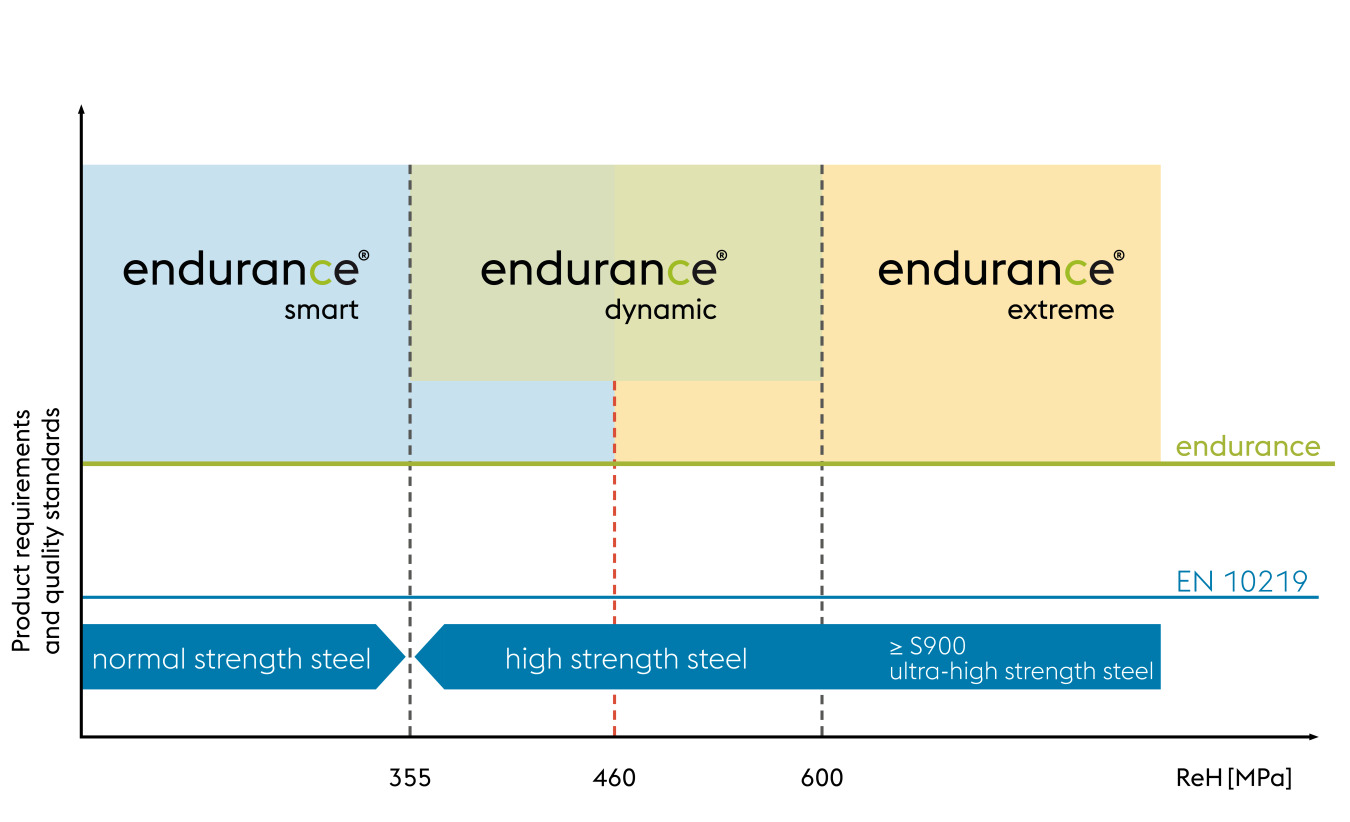

You'll be up to any challenge. Our universally applicable endurance smart, dynamic and extreme hollow sections show what they are capable of.

Brochure endurance hollow sections

Cold-formed hollow sections with advanced quality and efficiency

Forming quality products that provide the highest benefit to the customer from the best materials requires sophisticated processes and professional experts: voestalpine Krems has the expertise in processing and materials required for pioneering customised tubes and sections solutions – this makes us the preferred development and manufacturing partner beyond the roll-forming process.

Whether for extreme loads or dynamic stresses:

The high-precision hollow sections made of steel set new standards in terms of cost-effectiveness as well as quality. You will definitely find the optimum solution for your requirements within this product family.

Your advantages

- Excellent processing properties

Thanks to the high-quality primary material, we can assure you of trouble-free processing. The hollow sections are easy to cut, weld, coat and join. - Tested quality

- 100 % non-destructive testing of the weld seam for hollow sections that have to be supplied with specific testing.

- Precise definition of which steel grades are to be subjected to specific testing, and therefore which certificates are to be issued.

- Precise definition of the type of tests to be carried out for each steel grade and the scope of the test.

Tube width:

10 mm -

Tube height:

10 mm -

Steel strip width:

60 mm -

Steel strip thickness:

1,25 mm -

A product range that has it all:

Quality hollow sections for effective processing

The narrow gradation with up to 470 different dimensions makes it easy for you to find the most favorable hollow section dimension. The hollow sections also impress with flat surfaces for a clear design.

Benefits

- Excellent processing properties

- Extensive range of dimensions

- Visually and functionally outstanding

Material

- Steel grades acc. to EN 10305-5, EN 10219-1, 3 and EN 10149

with yield strenght up to 460 MPa

Brochure endurance hollow sections

Factory standard endurance smart

The standards EN10305-5 and EN10219 parts 1, 2 and 3 are used as the basis for the production of our square and rectangular tubes. In addition to the standard, our own factory standard endurance smart applies to tubes produced by voestalpine Krems GmbH.

We further restrict surface requirements, limit dimensions and many other parameters compared to the normative specifications. Ask your sales contact - we will be happy to advise you.

Cold-rolled hollow sections for dynamic loads

endurance dynamic combines an innovative material concept with many years of experience in roll forming at voestalpine Krems. The result is cold-formed hollow sections for dynamic loads, which bring together the cost advantages of cold forming with the quality advantages of hot-formed hollow sections.

Benefits

- High dynamic load bearing capacity – the ingenious section solution for agricultural machinery

- Benefits from two worlds - costs of a cold-formed & quality of a hot-formed hollow section

- Innovative material concept – significantly improved forming properties thanks to thermomechanically rolled steel with a high degree of purity

Our cold-rolled, longitudinally welded endurance dynamic hollow sections can replace tubes in accordance with EN 10210 in applications with dynamic loads.

In our factsheets you will find technical details on the topics of weldability, fatigue strength and other mechanical properties.

For the objective of independent and advanced characterization of endurance dynamic, we have conducted representative tests together with a university, based on typical loads on the tubes.

The focus was on the fatigue behavior of endurance dynamic compared to hot-finished tubes according to EN 10210 and was confirmed to be at least equivalent.

Count on a reliable solution

- voestalpine special steel grade

- Micro-alloyed and thermomechanically rolled high-purity steel

- Yield strength ReH [MPa] 355 – 600

High-strength and ultra-high-strength hollow sections for extreme requirements and efficient futher processing

Hollow sections made of high-strength or ultra-high-strength steels are extremely resilient - the increased strength and better fatigue behavior are decisive in terms of safety.

They also have outstanding forming properties, excellent weldability and are well suited for cutting and punching.

endurance extreme has even more to offer. The weight reduction of up to a third compared to comparable hollow sections with the same strength speaks for itself. As a result, you benefit from reduced fuel consumption in vehicles or increased payload.

Material

Fine-grained construction steels in accordance with EN 10149 from S500MC up to S960MC

Brochure endurance hollow sections

Extreme benefits

Optimum processing ability

The hollow sections made from high-strength steels are extremely resilient and feature outstanding forming properties. They are perfect for welding, cutting and punching purposes.

Major reduction in weight

Weight reductions of up to one-third with the same level of strength – this e.g. reduces fuel consumption in vehicles and increases load capacities.

Increased safety

Increased strength and better fatigue behaviour are the most important factors when it comes to extreme requirements.

Tomorrow's topics that are already of relevance to you and us today: