isovac® is more than just an innovative electrical steel

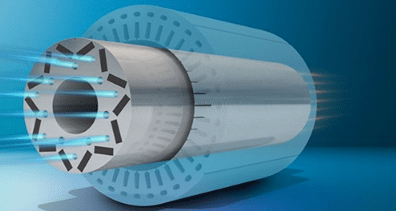

Smart, powerful and energy-efficient, isovac®, the non-grain-oriented electrical steel made by voestalpine, is convincing in many ways and is used in the production of motors, generators and static machines. With its special magnetic, mechanical and physical properties, the cold-rolled steel made of iron-silicon alloys sets new standards in energy efficiency and performance. Talk to us about your requirements. Our electrical steel experts are looking forward to meeting every challenge!

Energy-efficient electrical steel and pole sheets

Discover fully processed and semi-processed electrical steel as well as pole sheets that set new standards. The wide range of property profiles of isovac® is the reason that it is used in a wide range of applications. Find the right product with us!

Electrical steel made by voestalpine: powerful, reliable and sustainable

The electrical industry is one of the most diverse industries of all and harbors numerous demands and challenges, which is why voestalpine provides excellent materials as well as unique know-how, comprehensive advice and powerful logistics. Discover the benefits of isovac® for your project!

Highly efficient electrical steel for a brighter tomorrow

Our use of resources has a significant impact on the living conditions of future generations. With our isovac® electrical steel, you are actively shaping a future that is sustainable and environmentally friendly. Learn more about sustainability.

Highly versatile

Whether it be the generation, transmission, distribution or utilization of energy, voestalpine has the right product for a wide variety of applications.

isovac® Insights: charged with information

Numbers that speak a clear language

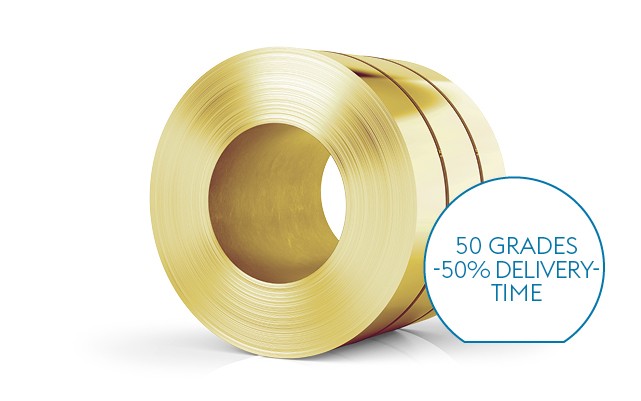

Highly efficient electrical steel with an added bonus

Maximum flexibility and quick response times for your success: Benefit from our customised services. We are setting new standards at voestalpine while maintaining the highest level of service quality.

Always well informed

Do you want to dive deeper into the topic of isovac®? Are you interested in further information? Take advantage of our comprehensive consultation. We will be happy to assist you in any way we can.