Interview on field testing and serial production readiness

Insights into a cool innovation

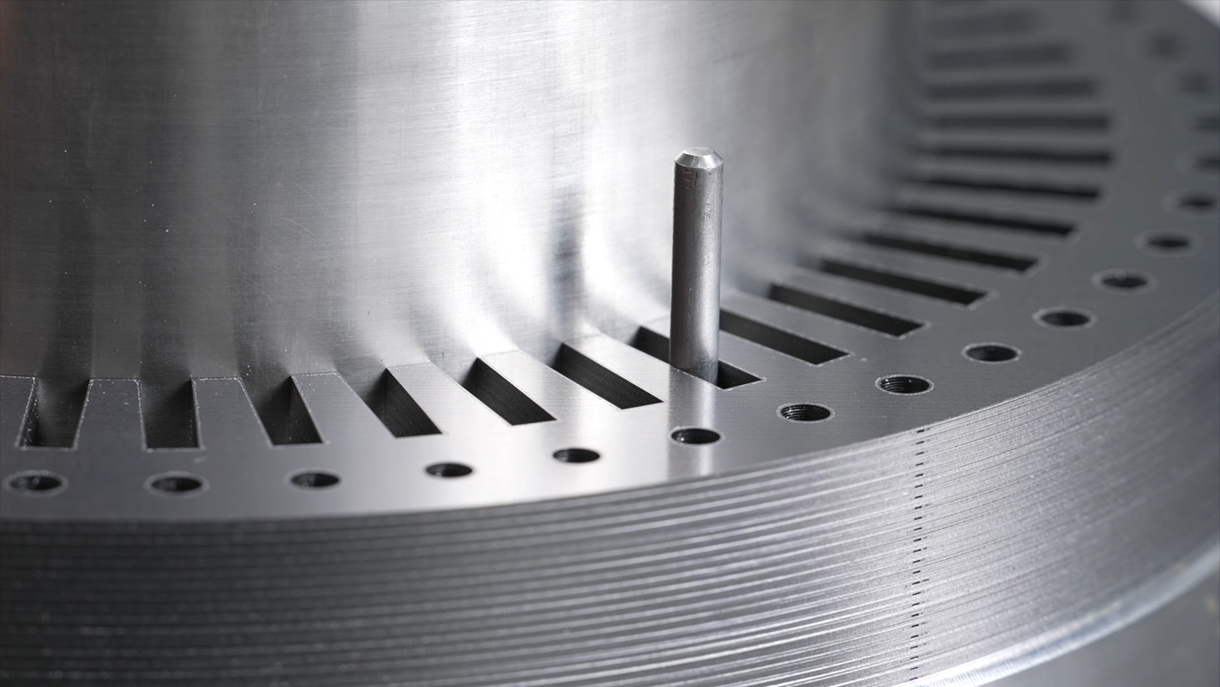

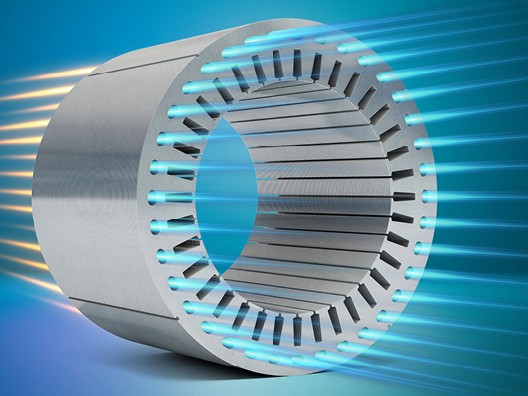

The technical specialists at voestalpine have succeeded in developing a manufacturing process for 100% media-tight, full-face-bonded stator stacks with integrated cooling. Does it work in the real world? Siegfried Silber of the Linz Center of Mechatronics and Ronald Fluch, Project Manager at voestalpine Stahl GmbH, provide insights into the proof of concept and the project status of this cool innovation.

A long list of benefits

- Integrated stator cooling for next-generation electric motors

- More compact, lighter weight, more powerful

- Adhesive-bonded with bonding varnish across the entire surface, 100% media-tight

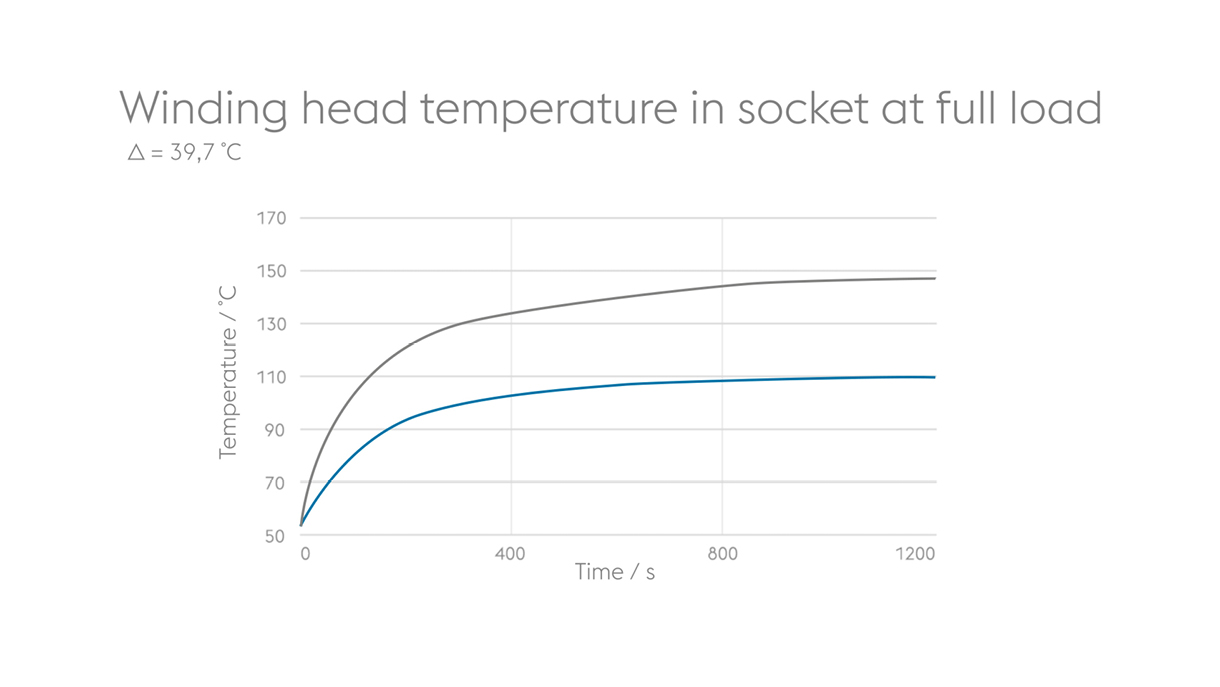

- Motor operating temperatures reduced by up to 40 °C

- For higher continuous torque with approximation of peak torque

- Cost savings through elimination of water jacket cooling, aluminum housing