voestalpine Core Pins

designed for pure performance

Engineered Products

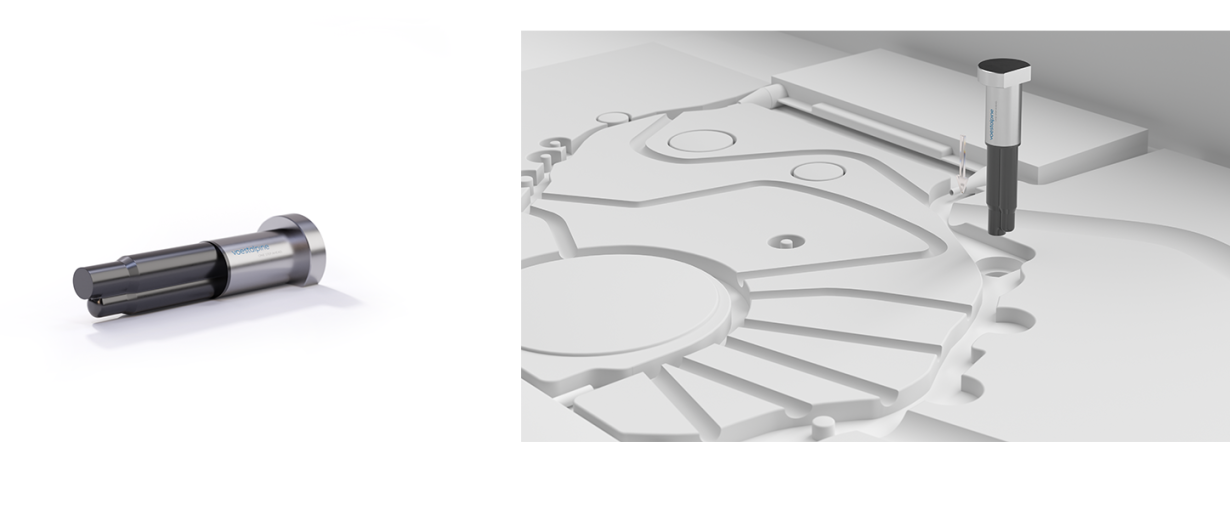

Core Pins for High & Low Pressure Die Casting

Core pins are frequently used to cast intricate designs. Due to the extremely high thermal loads in combination with extremely hot-temperature wear on these exchangeable parts, they are one of the most critical components in HPDC and LPDC tools. With constantly rising Al-part complexity, more and more core pins are required in DC molds. Our voestalpine Core Pins are the solution to these industrial challenges.

These ready-to-use components are made from premium materials by BÖHLER/Uddeholm and incorporate several state-of-the-art services, including machining, heat treatment and PVD coating. With this outstanding combination, productivity and lifetime are significantly increased.