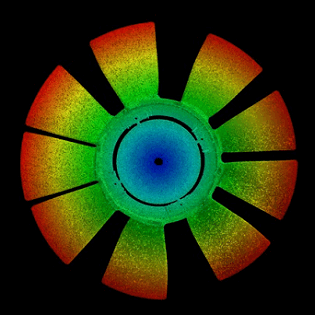

Computational Fluid Dynamics – Flow simulation for injection molding, temperature distribution, processing times, and impact of different cooling configurations

Customers benefit from access to a full suite of advanced modelling and simulation tools. From using leading edge technology and software expertise, customers can be assured the solution developed is feasible, technically and economical optimized, and fully exhaust all possibilities of error before moving into prototypes and fabrication.

The services offered can be part of an integrated solution development, as part of continuous improvements, or as part of troubleshooting efforts. The analytical tools are valid for conventional fabrication processes and are particularly valuable when exploring the potential of Additive Manufacturing.