Additive Manufacturing Solutions for Oil & Gas

Oil & Gas

voestalpine Additive Manufacturing Centers have successfully collaborated with Technology and Manufacturing divisions in the Oil & Gas industry in both development and delivery of high quality Additively Manufactured components. These components are part of a Rotary Steering System for directional drilling tools.

Other applications include: measuring while drilling (MWD), logging while drilling (LWD), completion tools, as well as wellhead and rig applications.

Benefits of vAMC Solution for Oil & Gas:

- Shorter development lead time for prototyping

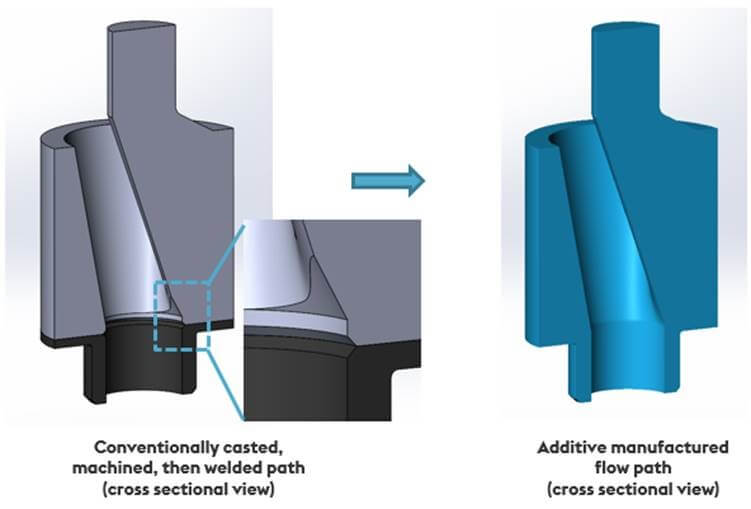

- Simplified manufacturing steps

- Stream-lined BOM & inventory

Components Applications

- Impeller

- Rotor & Stator

- Flow Guide/Manifold

- Valve & Pump Housing

- Mixer & Filter

Complete Solution – From Powder to Finished Component

Qualified Materials for Oil & Gas:

- Stainless Steel: 316L, 17-4PH

- Nickel-Based Alloys: Inconel 625, 718 AMS & API

- 718 bending, fatigue properties meet API 150ksi standards

- Cobalt-Based Alloy: CoCr MP1 (Stellite 21)

Manufacturing Capabilities:

- Printing: Powder Bed Fusion AM

- Thermal Processing: Heat Treatment, Hot Isostatic Pressing

- Machining: 5-Axis turn mill

- Coating: PVD, HVOF

- Dimensional Inspection: CMM and laser 3D scanner

- Non-Destructive Testing: Liquid Penetrant Test, Leak Test, CT Scanning

Other Services:

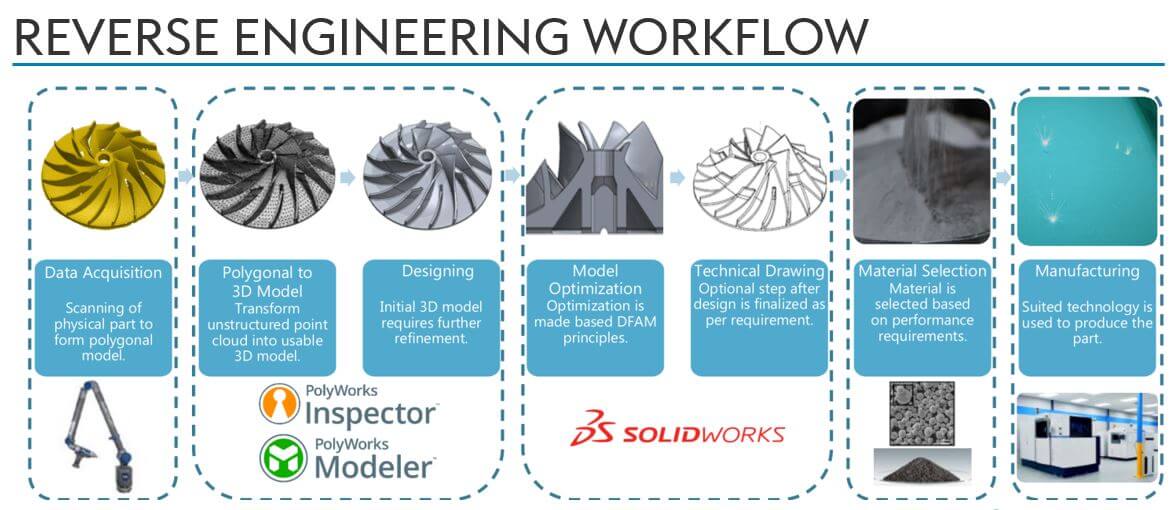

Digital Warehousing & Creating Digital passports

- Data Acquisition

- Polygonal to 3D Model Transform

- Designing

- Model Optimization

- Technical Drawing

- Material Selection

- Manufacturing

AS 9100 & ISO 9001:2015 Combined Certification

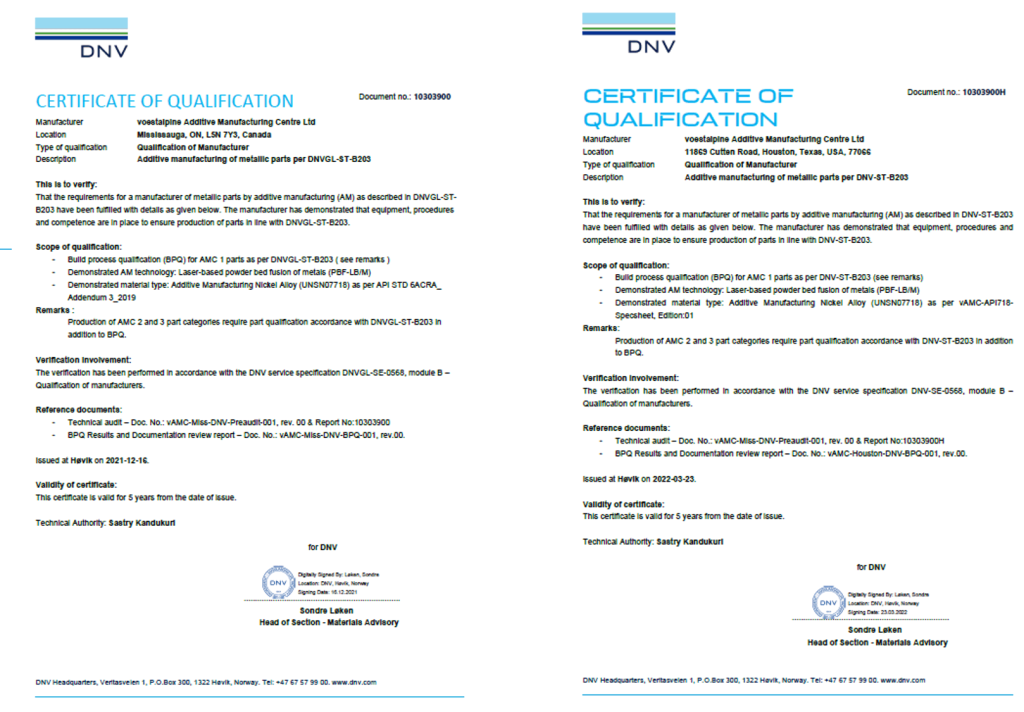

vAMC DNV Certification for Oil & Gas

Downloads

- Quality Certificate Houston – ISO 9001-2015 pdf | 162 KB

- Quality Certificate Mississauga – AS 9100 D & ISO 9001:2015 pdf | 422 KB

- vAMC DNV Certification Houston – DNV-ST-B203 certification to benefit the Oil & Gas industry pdf | 551 KB

- vAMC DNV Certification Canada – DNV-ST-B203 certification to benefit the Oil & Gas industry pdf | 531 KB