THE NEXT GENERATION OF DIE CASTING INSERTS

OUR APPROACH

For decades voestalpine and its core steel brands BÖHLER USA and UDDEHOLM USA have been recognized as global leaders in the manufacture and the supply of high performance tool steels. As a result we understand the unique challenges that our customers face in the High Pressure Die Casting industry.

Working closely with our customers, we follow our three pillared approach of Optimized Design, Optimized Powder and Optimized Printing, using state-of-the-art Additive Manufacturing know how to develop bespoke 3D printed tooling inserts for the toughest High Pressure Die Casting Industry applications.

Your trusted Additive Manufacturing partner.

OPTIMIZED DESIGN

We support our customers through a detailed consultation process to develop the right solution for the right application, where needed our High Pressure Die Casting experts can help our customers re-design tools and inserts according to the exact requirements of their application.

Our data driven approach to cooling channel design analyzes processing parameters and mechanical loads to develop detailed computer models and process simulations (digital twins) of each customers HPDC application. This method of optimizing thermal management is essential to ensure the right balance between efficient cooling and maximizing the mechanical performance of the tool.

This process goes far beyond regular conformal cooling channel design. We understand High Pressure Die Casting.

OPTIMIZED PRINTING

We ensure the highest possible quality, reliability and consistency by managing every step of the value chain from powder production to the delivery of the finished part. Whether for a single part order or series production, our internal quality systems ensure we meet your requirements every time.

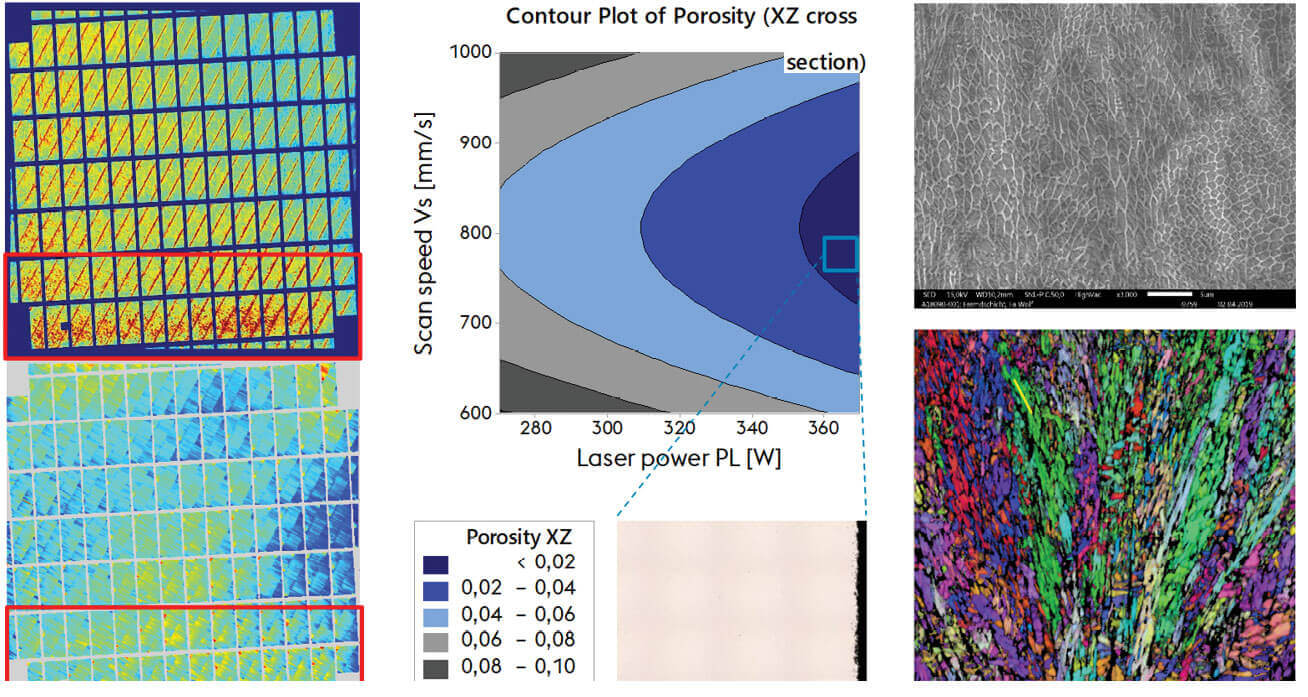

Design of Experiments, Statistical Process Control, and Process Monitoring form the basis of our printing methodology. Continued innovation from our voestalpine Additive Manufacturing Centers ensures our printing processes deliver superior material properties and tool performance every time.

We understand the interactions between laser and material. This deep understanding of Additive Manufacturing and Injection Molding allows our customers to add value to their business from the first shot.

Left: Optimization goal ¨build zone¨ detected by process monitoring using EOSTATE Exposure OT (top) and EOSTATE MeltPool (below).

Middle: Design of Experiments for parameter optimization using contour map of response surface design for porosity (top) and the related metallographic sample after optimization (below).

Right: Microstructure of AM processed H13-type analyzed by SEM (top) and EBSD (below).

OPTIMIZED POWDER

Our long history of developing high performance tool steels at BÖHLER and UDDEHOLM for the Die and Mold industries gives us a unique perspective on the needs of the High Pressure Die Casting industry when adopting Additive Manufacturing. Our powders and printed materials are designed to deliver improved performance over standard wrought material grades.

The highest quality materials, deliver superior tool life.

BÖHLER W722 AMPO

BÖHLER W722 AMPO is our standard 1.2709 maraging steel grade for High Pressure Die Casting applications. This grade has been proven to deliver benefit when combined with properly engineered conformal cooling, with similar performance to 1.2343 ESR (H11) and 1.2344 ESR (H13).

IN SHORT:

- Great toughness

- Recommended hardness in use: 42-50 HRC

- Little to no restriction in insert geometry

BÖHLER W360 AMPO

BÖHLER W360 AMPO is our premium high hardness grade for High Pressure Die Casting applications. This proprietary grade has been designed to outperform many traditional tool steels such as 1.2343 ESR (H11) and 1.2344 ESR (H13).

IN SHORT:

- High temper back and hot wear resistance

- Recommended hardness in use: 48-50 HRC

- High toughness

- Ideal for high-stress, high temperature areas

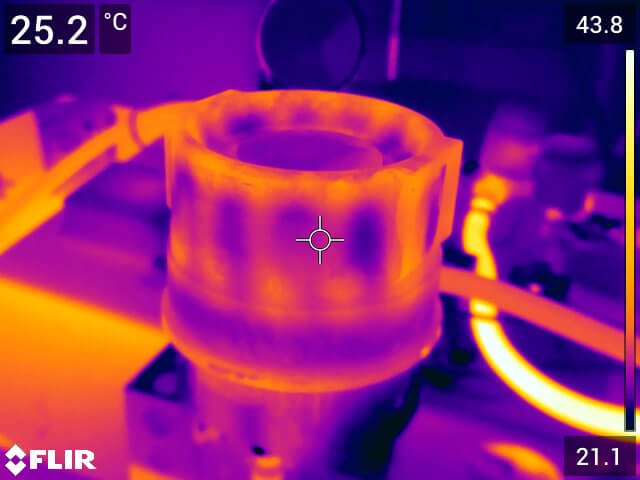

ADVANCED INSPECTION

In addition to dimensional and material property testing for each AM build, vAMC has developed dedicated inspection rig and methods for Conformal Cooling channels:

- Flow parameter test: verify pressure vs. flow rate against simulation results

- Leak test: pressurize and hold up to 150 psi

- Thermal test: check channel condition via thermal image showing temperature distribution during hot/cold water cycle

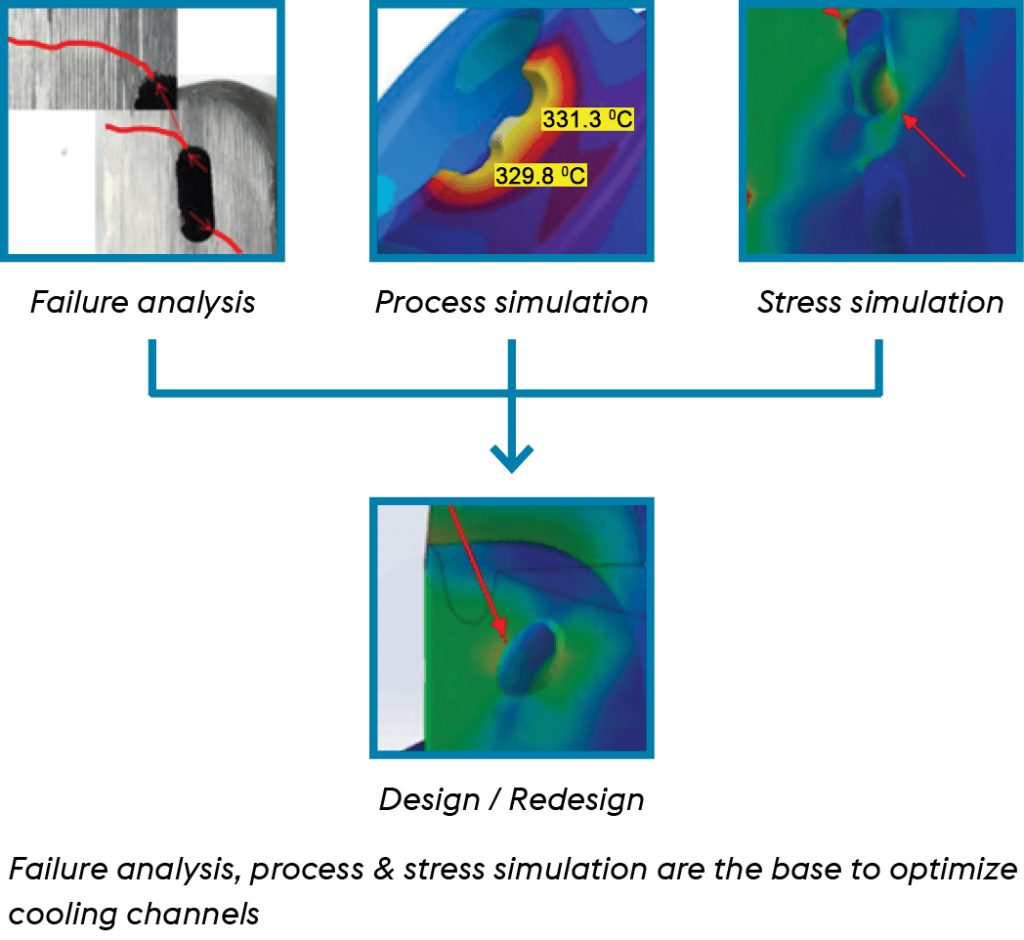

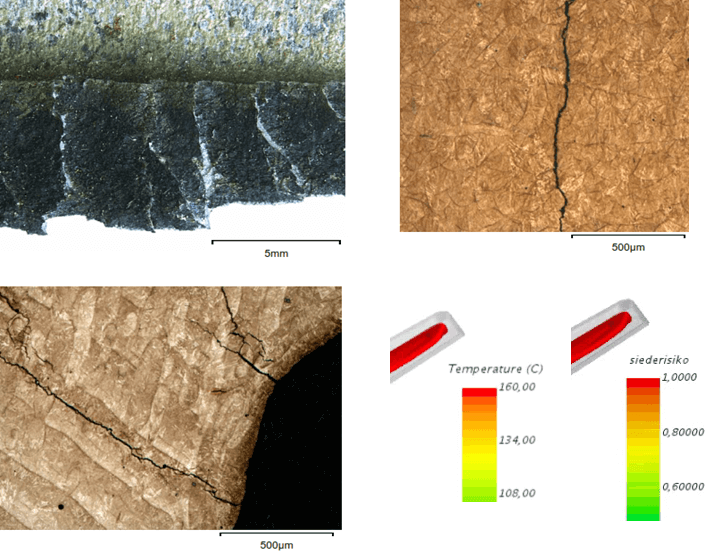

FAILURE ANALYSIS

Our support does not end with the delivery of printed inserts. It goes far beyond that. Every tool has a finite lifespan and will fail at some point. We analyze examine the failed tooling insert to determine the root cause of failure, identify potential problems, and extend the life of the tool.

For example, cracking can have many different root causes. Only those who understand the issue can take the necessary actions to extend the service life of the tool.

Images show cracks that have occurred due to poor channel design.

Left: macroscopic image of cracks in the tool with scaling in the cooling channel (top) and microscopic image of cracks in the LOM (bottom)

Right: microscopic image of a crack (top) and simulation results (bottom)