INNOVATION LAYER BY LAYER

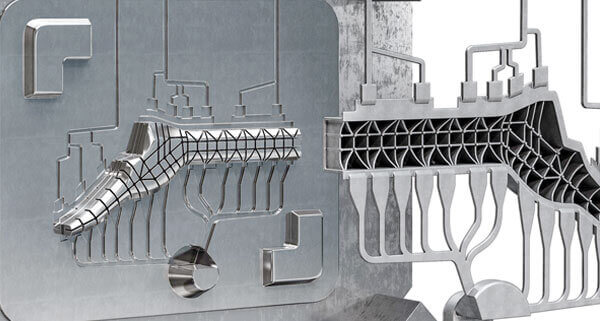

PLASTIC INJECTION MOLDING

Conformal cooling channels can be designed to accommodate existing tooling hardware, such as ejector pins and hot runner systems, allowing new and existing tooling to be improved with minimum disruption.

Correctly designed and well implemented conformal cooling systems can result in reduced cycle times, lower defect rates, and higher tool productivity.

Visit our dedicated Plastic Injection Molding page for more details.

HIGH PRESSURE DIE CASTING

When we combine the capabilities of Additive Manufacturing with our unique materials and state-of-the-art cooling system designs, our AM high pressure die casting inserts consistently out perform their conventional counterparts.

This results in additional value for our customers through the reduction of cycle times, lowered frequency for maintenance and fewer part defects.

Visit our dedicated High Pressure Die Casting page for more details.

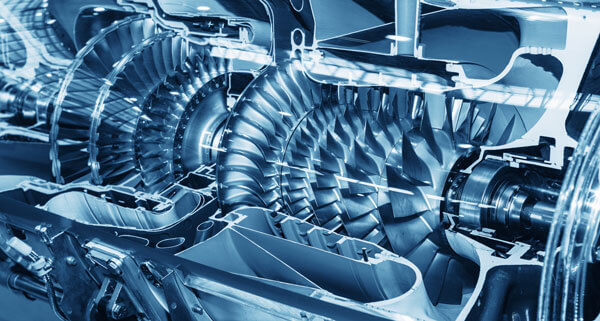

OIL & GAS / MARINE

Our history of producing high performance alloys for the oil & gas industry, means our Additive Manufacturing solutions are designed to meet the most stringent industry quality requirements.

We use state-of-the-art technologies to support our AM processes from initial concept through to finished functional parts. Our focus on both Laser Powder Bed and Laser Powder Deposition technologies means we can support a range of Oil & Gas applications.

Visit our dedicated Oil & Gas page for more details.

AEROSPACE

We supply a wide array of high performance materials to the aerospace and automotive industries, these include forgings, high quality steels for dies and molds, and specially alloys for finished components.

Our experience of supporting these industries flows directly into the implementation of Additive Manufacturing ensuring we continue delivering that support into the future.

Visit our dedicated Aerospace page for more details.