Sustainability

we are on a mission

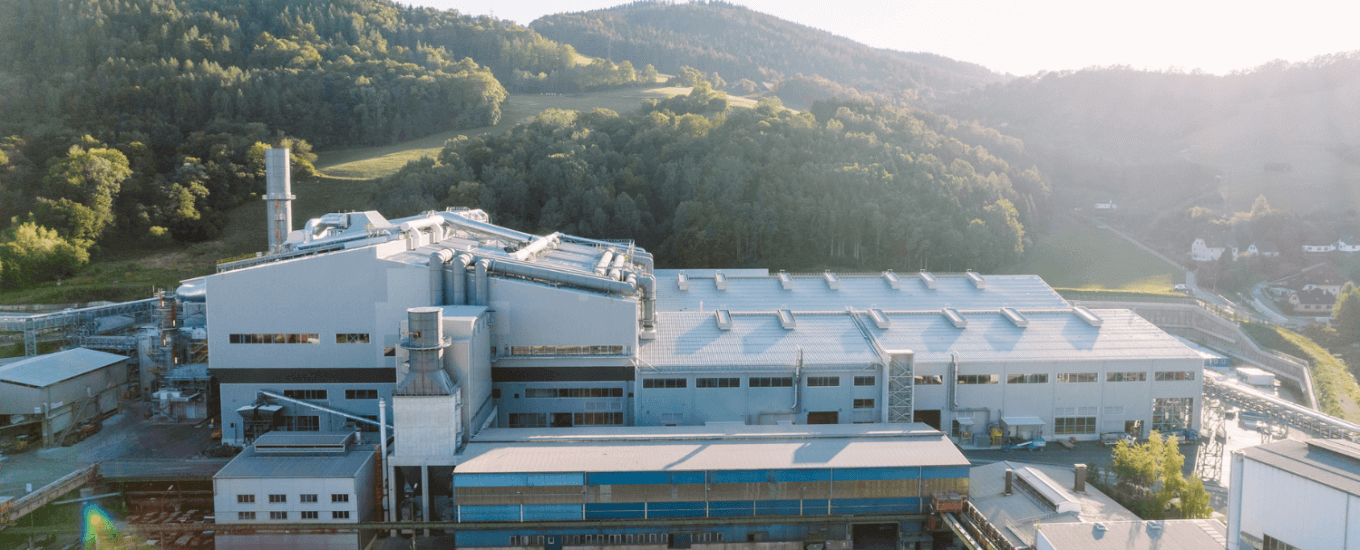

As the world’s leading supplier of high performance materials with an unique service network that ensures customers confidence, we establish sustainable performance beyond expectations for our planet and generations to come. With our integration of products, services and technical advisory we create a profound impact on our business area. Leading by example, we enable our customers to engage in sustainable initiatives while also driving our suppliers and partners to be at the cutting edge of essential transformation processes for tomorrow. Together, we inspire the change in our industries by always thinking and walking one step ahead.

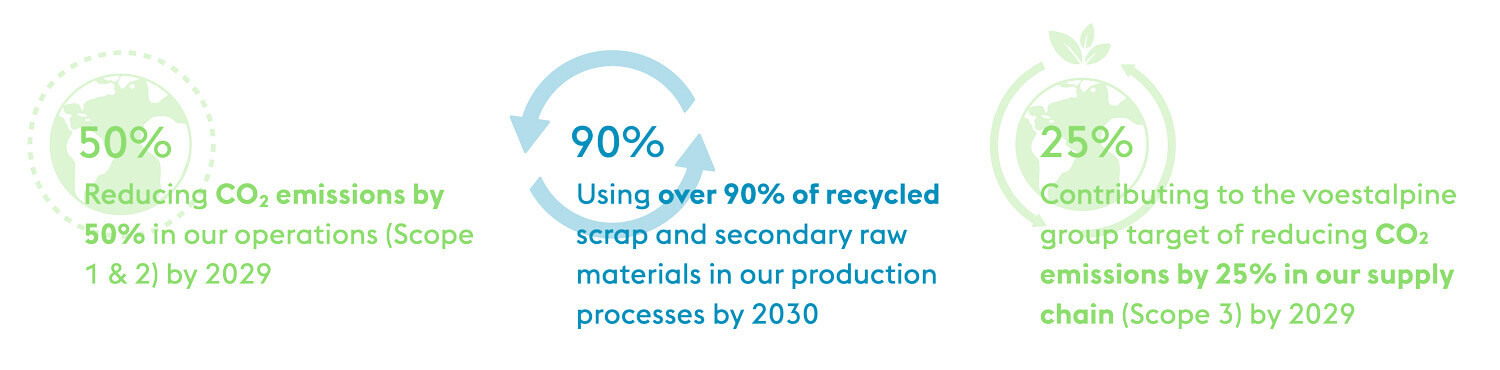

our main sustainability goals

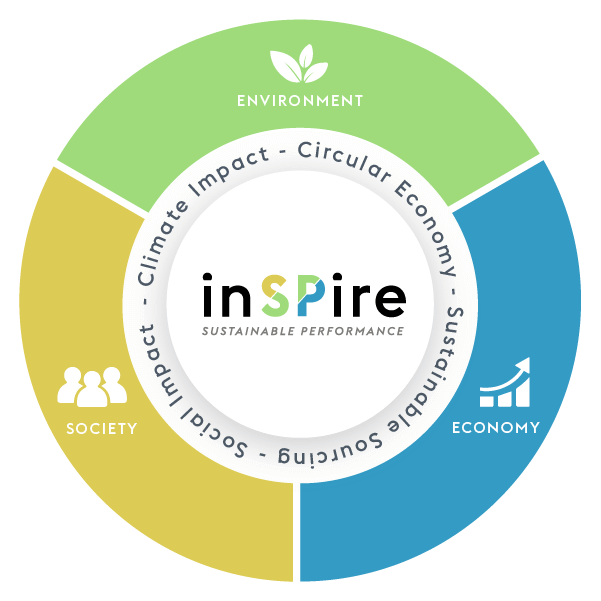

Our sustainability framework inSPire is here to stay

Every transformation needs a vision. To bring that vision into action, a specific strategy and goals to drive daily operations are indispensable.

Our goals are clear, we seek to make considerable contributions in the areas of circular economy and climate impact. This is why we have developed our very own sustainability framework outlining our four focus topics and respective sustainability actions while addressing all pillars of sustainability.

our focus topics

Within our sustainability strategy, we focus on four different content pillars, connected to specific fields of action. Latter include specific initiatives and goals, leading us in our daily operations.

Material/scrap cycles, alternative raw material sources, recycling of by-products, zero waste

Decarbonization, green energy & energy efficiency

Sustainable procurement by integrating social, ethical & ecological factors

Promoting social aspects of sustainability

our contribution to your sustainable performance

Our ambition is to support our customers in their transformation towards carbon neutrality: by making carbon footprints of our products and services transparent, closing material loops and therefore collaborate jointly on the reduction of the produced parts’ carbon footprint. Find out more about our customer solutions here:

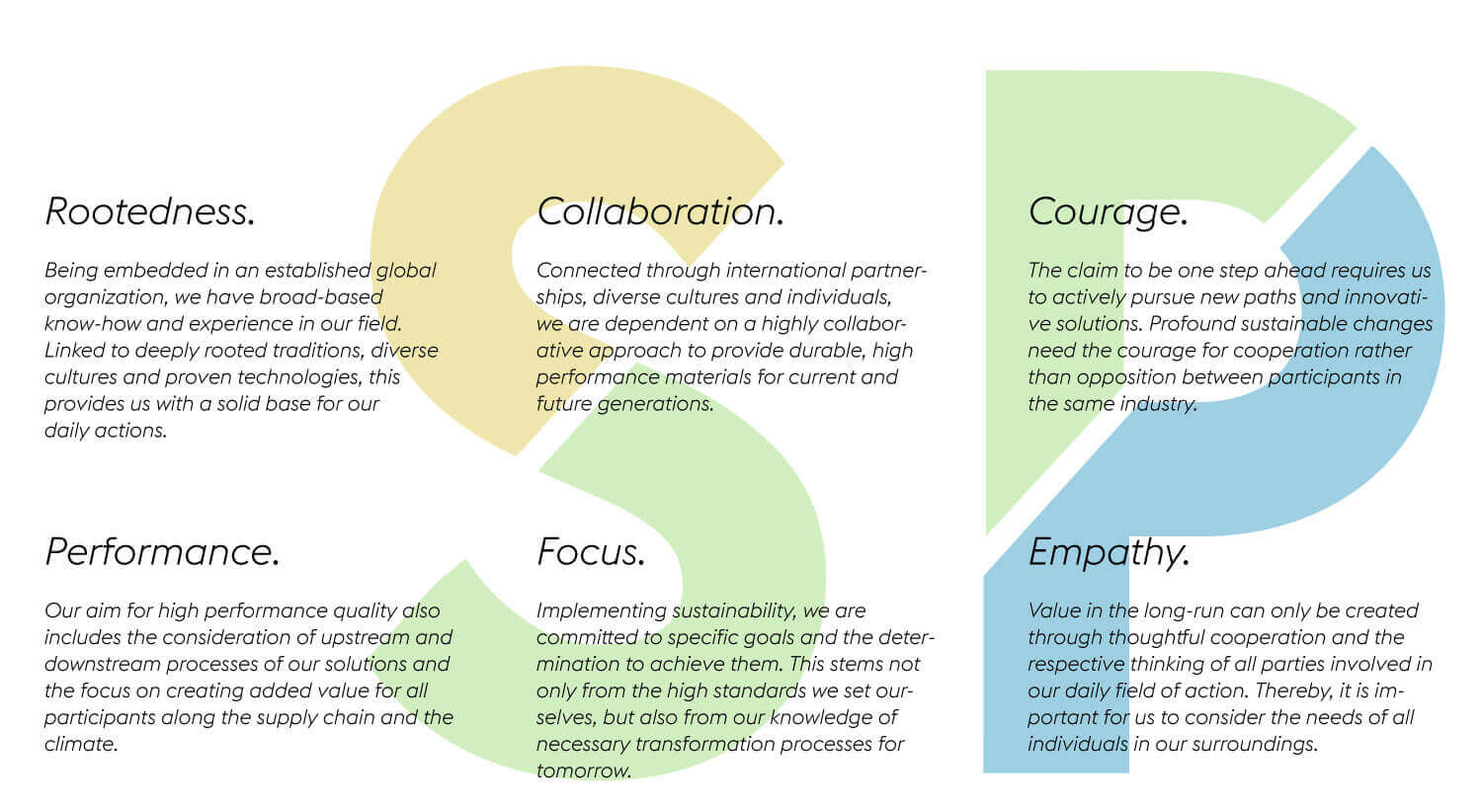

our values

Within our inSPire sustainability framework we live and act according to the following values shaping and leading us in our daily actions and operations

download

Find out more about inSPire including some interesting examples of our focus topics and download our inSPire brochure here.

inSPire & The UN’s Sustainable Development Goals (SDGs)

In our inSPire framework, we are committed to the United Nation’s Sustainable Development Goals (SDGs). Our inSPire action fields contribute most to the following four SDGs: (8) Decent Work & Economic Growth, (9) Industry, Innovation & Infrastructure, (12) Responsible Consumption & Production, (13) Climate Action.

contact

Philipp Horner

Chief Sustainability Officer

“We value sustainability as an opportunity which is why we have set ourselves ambitious targets as part of our sustainability strategy.”

Philipp Horner, CSO voestalpine HPM

get inspired: news & more information

Division blog

Division blog

inSPire: Our sustainable development goals

When we do something, we do it with passion, authenticity and conviction. This also applies to our sustainability initiatives in the context of inSPire. To frame our activities even more precisely, we have mapped “our” Sustainable Development Goals (SDGs) from the United Nations’ 2030 Agenda for Sustainable Development.

Read more Division blog

Division blog

Social Impact: By People for People

Every company influences the people who work for it as well as those outside the organisation. The same is true of us in the High Performance Metals Division (HPM). With the Social Impact pillar of our “inSPire” sustainability framework, we focus intensively on consciously managing this social impact.

Read more Division blog

Division blog

voestalpine HPM solutions for melt filtration of 1st generation and recycled plastics

In this article we briefly discuss the increased use of recycled plastic in injection molding as part of the solution for a carbon-neutral circular economy. We also show how voestalpine High Performance Metals (HPM) has developed filter solutions to remove contaminants in the plastic melt, allow the mixing of plastic materials, and minimize machine pressure drop associated with filtration.

Read more Division blog

Division blog

inSPire: social responsibility practised together

Social Impact, “Social Engagement”, Corporate Social Responsibility: What does this mean in concrete terms for a company and specifically for us as the High Performance Metals Division? We are witnessing not only increasing political, legal and social expectations regarding the fulfilment of ESG (Environmental, Social, Governance) criteria. Social responsibility has also become an important factor for remaining attractive as an employer.

Read more Division blog

Division blog

ESG in our supply chain and the role of sustainable sourcing

Efficiency is a top priority for us here at the High Performance Metals (HPM) Division and this also concerns our eneSustainable sourcing is much more than just an economic responsibility. When procuring raw materials, companies must ensure responsible corporate governance and respect for human rights, all the while striving for environmental protection.

Read more Division blog

Division blog

Sustainable Sourcing: Climate Protection through Sustainable Procurement

Sustainable procurement is becoming increasingly important in active climate protection. At the same time, it is an essential part of any sustainable business model.The High Performance Metals (HPM) Division is already taking this into account and has created its own sustainable sourcing pillar as part of its sustainability framework “inSPire” to keep it on the cutting edge of this complex topic.

Read more Division blog

Division blog

Energy supply of the future: Promoting environmentally friendly energy

Efficiency is a top priority for us here at the High Performance Metals (HPM) Division and this also concerns our By drawing from environmentally friendly energy supplies, we can sustainably cover large parts of the energy requirements of the High Performance Metals Division. We also aim to achieve the ambitious goal of climate neutrality by 2050. To make this possible, we are focusing on the use and promotion of green energy sources under the Climate Impact pillar of our sustainability framework inSPire.

Read more Division blog

Division blog

Decarbonization: Reducing greenhouse gas emissions for a positive effect on the environment

Significantly reducing our emissions is one of the High Performance Metals (HPM) Division’s explicit goals. Reducing Scope 1 and 2 emissions is therefore a key area of action under the Climate Impact pillar of our inSPire sustainability framework. And a wide range of measures are bringing us closer to that goal: ambitious decarbonization roadmaps and real-world projects for greater energy efficiency, less natural gas, and an increased use of renewable energies.

Read more Division blog

Division blog

eco2nboard: The transparent carbon footprint

Efficiency is a top priority for us here at the High Performance Metals (HPM) Division and this also concerns our energy use.We have been working for some time already on integrating all aspects of sustainability into daily operations with our “inSPire” framework. Thanks to our newly developed carbon footprint calculations at product level – eco2nboard – we are now able to evaluate the environmental impacts of HPM products even better, and make them available to our customers in a transparent format.

Read more Division blog

Division blog

HPM focuses its efforts on energy efficiency: Making full use of potential

Efficiency is a top priority for us here at the High Performance Metals (HPM) Division and this also concerns our energy use. There is great potential here for cutting emissions and costs, as well as for promoting alternative energies.

Read more Division blog

Division blog

voestalpine HPM tooling solutions increase performance and reduce carbon emissions

Wherever your manufacturing business lies in the value chain, your ability to increase productivity and reduce carbon emissions are key competitive factors. In this article, we share a recent case study showing how one of our customers in the automotive industry addressed these factors by using a voestalpine Sub Insert in their high pressure die casting operation.

Read more Division blog

Division blog

Alternative raw material sources: The potential of batteries

In addition to steel scrap, alloy elements such as nickel, cobalt, manganese, and other alloys are essential components of our products. However, various global developments are affecting the availability of these critical raw materials. Within our sustainability framework inSPire, the High Performance Metals Division is looking for long-term ways to keep these valuable elements in the product cycle, for example by recycling grinding sludge or batteries in order to be able to meet demand in the long term.

Read more Division blog

Division blog

Climate Impact at HPM: Our contribution to climate protection

Within the High Performance Metals (HPM) Division, the “Climate Impact” pillar is dedicated to the topic of climate protection as part of inSPire. The focus is on decarbonization through improved energy efficiency, electrification, and the use of renewable energies.

Read more Division blog

Division blog

Sustainable performance inSPires

At the High Performance Metals (HPM) Division, we believe that true sustainability transformation starts from within. This means we set out to inspire with our actions.

Read more Division blog

Division blog

Recycling of by-products: “Waste” with added value

Within the High Performance Metals (HPM) Division, the “Climate Impact” pillar is dedicated to the topic of climate pScale, dust, and slag can be used as secondary sources of raw materials—by-products that have traditionally been seen as waste often contain valuable resources. At HPM, we have long been committed to recycling the by-products from our production sites and reintegrating them into the value chain. The inSPire Circular Economy team is working to develop this topic further across several projects. In this article, we take a look behind the scenes.

Read more Division blog

Division blog

Closing the loop with circular Economy

The concept of the circular economy with a closed material and energy cycle replaces the traditional linear economy. At the High Performance Metals Division, we have set ourselves the goal of consistently implementing this model under inSPire in our business processes, for example through projects to further develop material and scrap cycles and to recycle end-of-life (EOL) tools.

Read more Division blog

Division blog

Circular Economy in the HPM Division: From waste to value

Within the High Performance Metals (HPM) Division, the “Climate Impact” pillar is dedicated to the topic of climate pScale,Efficient recycling of resources has long been a major concern for us. For this reason, the circular economy represents a key field of action, which we would like to develop further as one of the four supporting pillars in our sustainability framework inSPire.

Read more Division blog

Division blog

Sustainability with real value

Creating a sustainability framework is one thing. Filling it with life and integrating it into everyday work is another. Authentic values and impactful projects help make this approach a success.

Read more Division blog

Division blog

Teamwork makes the dream work – Part 1

Within the High Performance Metals (HPM) Division, the “Climate Impact” pillar is dedicated to the topic of climate pScaleIn our sustainability framework inSPire, we highly value teamwork. Our committed pillar teams actively contribute to knowledge sharing and collaboration. Find here the first team portraits for Circular Economy and Climate Impact.

Read more Division blog

Division blog

Teamwork makes the dream work – Part 2

In our sustainability framework inSPire, we highly value teamwork. Our committed pillar teams actively contribute to knowledge sharing and collaboration. Read part 2 now to find out more about our colleagues responsible for Social Impact and Sustainable Sourcing.

Read more Division blog

Division blog

inSPire is here to stay

We are on a mission. A mission we pursue with deep conviction and commitment: We strive for long-lasting performance that meets the needs of our planet and future generations. inSPire offers the framework and inspiration for this.

Read more

Uddeholm receives award

Schaeffler AG awards Uddeholm Germany with the supplier award “sustainability”.

Read more

Shaping the world

Our subsidiary Uddeholm is manufacturing solutions for generations to come.

Read more

Taking responsibility seriously

International environmental and social initiatives on voestalpine group level

Read more

Driving Innovation

Sustainability strategy and actions taken at voestalpine Böhler Edelstahl

Read more