Produktkategorie: Engineered Products

voestalpine Venting Insert Round

designed for pure performance

Proper venting in injection molds is crucial for releasing trapped air and gases. This ensures optimal material flow, uniform cavity filling, and high-quality parts. Inadequate venting can lead to defects such as short shots, burn marks, voids, and weak weld lines, compromising part integrity and appearance.

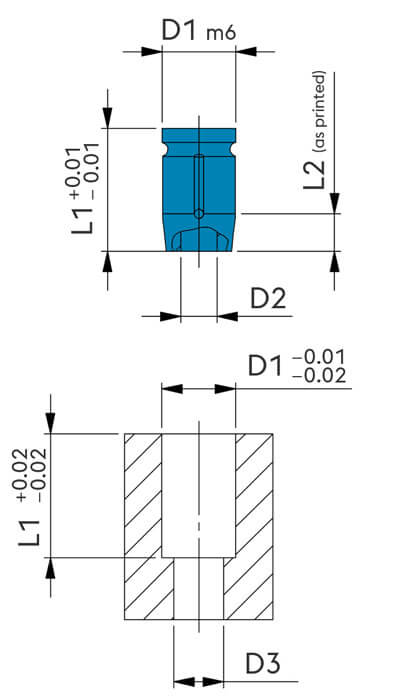

By leveraging the possibilities of additive manufacturing, voestalpine solves these challenges with porous, corrosion-resistant tool steels for injection mold inserts. Microscopic pores allow gases to escape directly through the mold surface without affecting structural strength. The standard component voestalpine Venting Inserts are compact porous plugs, which are easy to integrate into molds, boosting productivity, reducing waste, and ensuring superior part quality.