Precision Strip

NEW OPPORTUNITIES. NEW IDEAS

Precision Strip UK

As part of voestalpine High Performance Metals, our specialist Precision Strip UK team support a wide range of demanding sectors, working closely with our mills to deliver tailor made solutions to our customers. We have the ability to hold extensive stock in our purpose built, award-winning UK warehouse facility located at our Headquarters in Oldbury, West Midlands, which is backed by stock at our Uddeholm and Bohler strip mills.

Our UK facility is accredited with ISO certifications 9001, AS9120 and OHSAS 18001 so you can be rest assured that the services provided are of the highest quality.

Meeting high demands

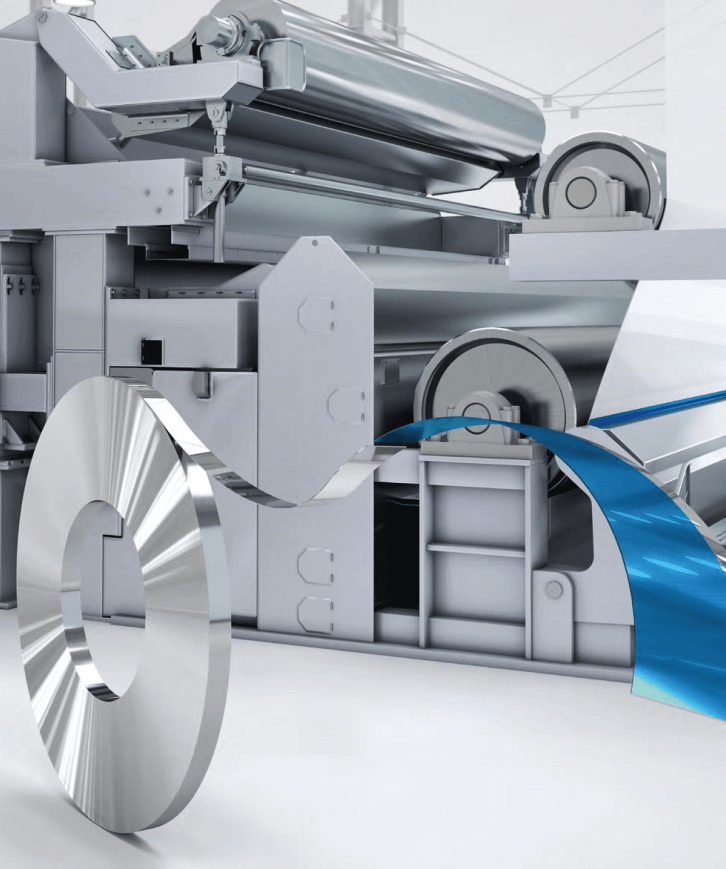

Paper and printing

- Coater Doctor Blades

- Printing Doctor Blades

- Creping Doctor Blades

Benefits:

- Reliable operation

- Long lasting service life

- Consistently superior quality

- Uniformity and high strength

Razor and scalpel blades

We supply cold rolled and unhardened, martensitic stainless and high carbon strip steel for the manufacture of razor blades and

medical scalpel products.

Benefits:

- Tightly controlled width and thickness tolerances, that facilitate faultless grinding

- We offer the full range of thicknesses and widths in standard pancake coils

- Narrow and thin strip supplied in traverse wound

Medical applications

The medical industry needs cold rolled steel that meets the high demands in this sector.

Benefits:

- Superior fatigue properties

- High degree of steel purity

- Excellent toughness

- Consistent and uniform quality

In a valves lifetime

Precision Strip valve steel meets the challenging demands on material properties such as high ultimate tensile strength, flatness, surface

finish and steel cleanness.

Benefits:

- Reliable operation

- Long lasting service life

- Consistently superior quality

- Uniformity and high strength

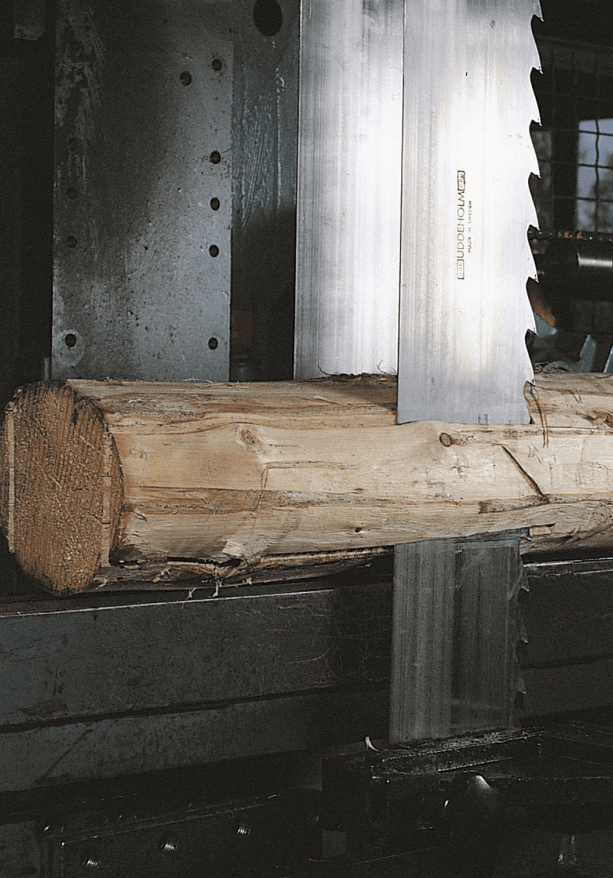

Performance blades

- Industrial Knives

- Wood Band Saw

Benefits:

- High wear resistance

- High fatigue strength

- Uniform blade quality

- Good elasticity and resilience

- Supplied in coils or cut to length

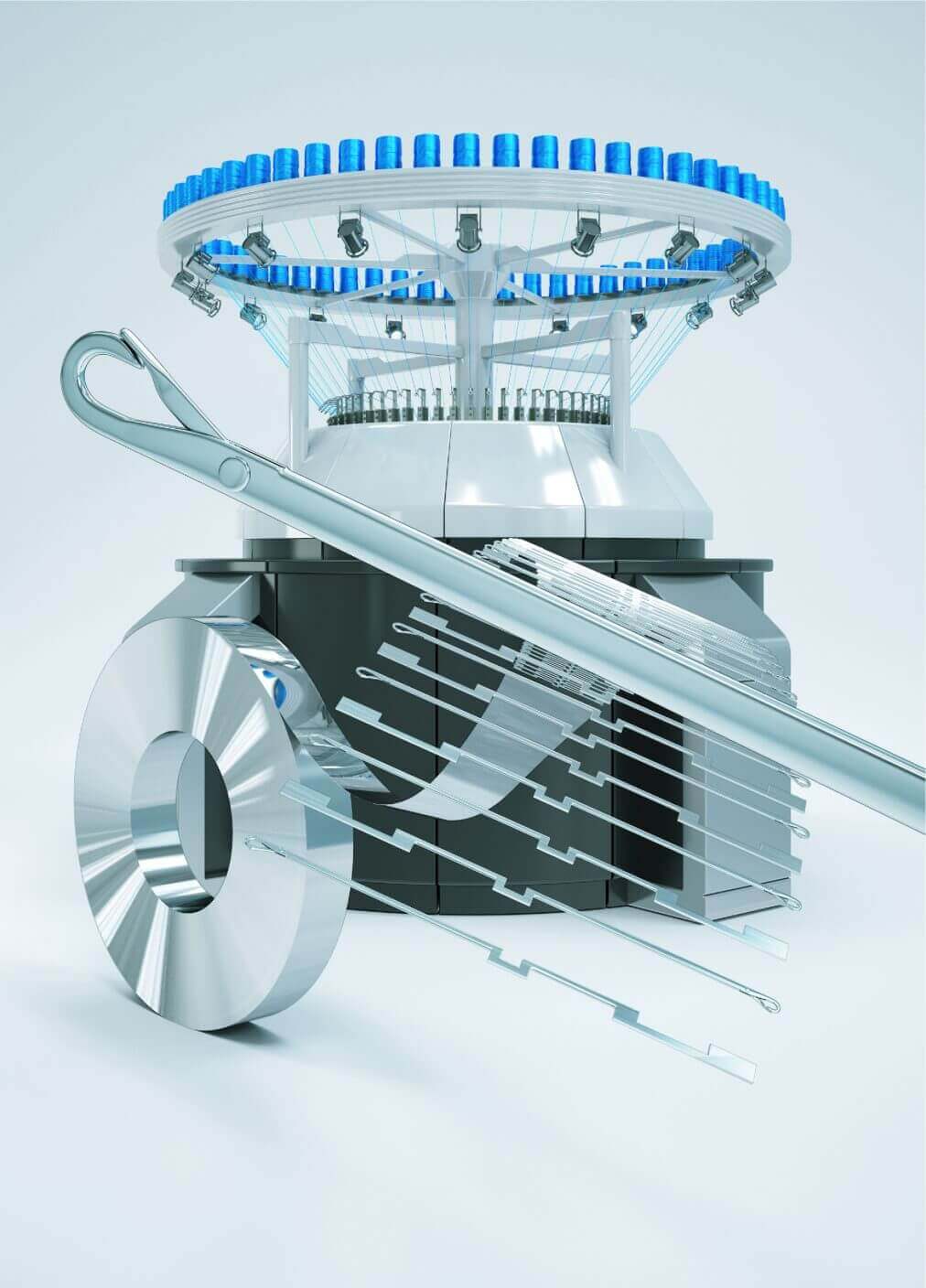

Textile needles

The textile industry demands needles with high fatigue strength and high wear resistance.

Developed specifically for latch needles, UHB 20MC1 is a 1% carbon low chromium steel developed in close cooperation with leading

needle manufacturers.

Benefits:

- Best available wear resistance

- High degree of steel purity

- Excellent durability after hardening

PRODUCT DEVELOPMENT

Added value from a combination – our strength lies in the combination of the latest technologies. From there we develop innovative added value in the application of steel as a material. By joining steel with different metallurgical and physical properties. By cold rolling, annealing, welding or hardening procedures for strip steel with edges or surfaces exhibiting a richness of variation. And with first-class metallurgical quality with specific strip steel machining.

Material expertise – in association with the voestalpine Group, we control all quality parameters, starting from the specific selection of steel grades. With around 30 steel grades used in day-to-day business, we schedule a finely aligned portfolio that enables us to offer short delivery times and small production volumes. Whenever new ideas for new applications require it, we develop project-specific alloy formulas together with our customers.

Machining expertise – when working steel strips, we combine technological expertise with industrial power – with a latest-generation cold rolling mill in Kematen, Austria and with unique capabilities in Munkfors, Sweden, all distributed through our UK based Headquarters.

E: ukstrip@voestalpine.com

Downloads

- Precision Strip UK Brochure pdf | 6.19 MB

- Shock Absorber Steel Brochure pdf | 1.37 MB

- Razor Scalpel Brochure pdf | 1.28 MB

- Special Steel Brochure pdf | 1.31 MB

- Flapper Valve Steel Brochure pdf | 1.24 MB

- Printing – Doctor Blades Brochure pdf | 3.01 MB

- Creping – Doctor Blades Brochure pdf | 1.49 MB

- Coater – Doctor Blades Brochure pdf | 1.28 MB