Plastic Injection Molding

Engineered Products for Plastic Injection Molding

We offer tailor-made solutions to address the industrial manufacturing needs of companies such as injection molders and tool makers operating in the plastic injection molding industry. The innovation behind our products is driven by our customers’ needs to optimize productivity, increase overall equipment efficiency, and minimize their total cost of ownership.

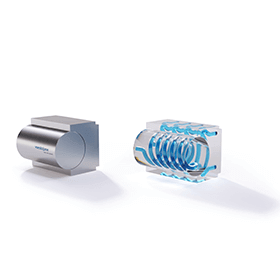

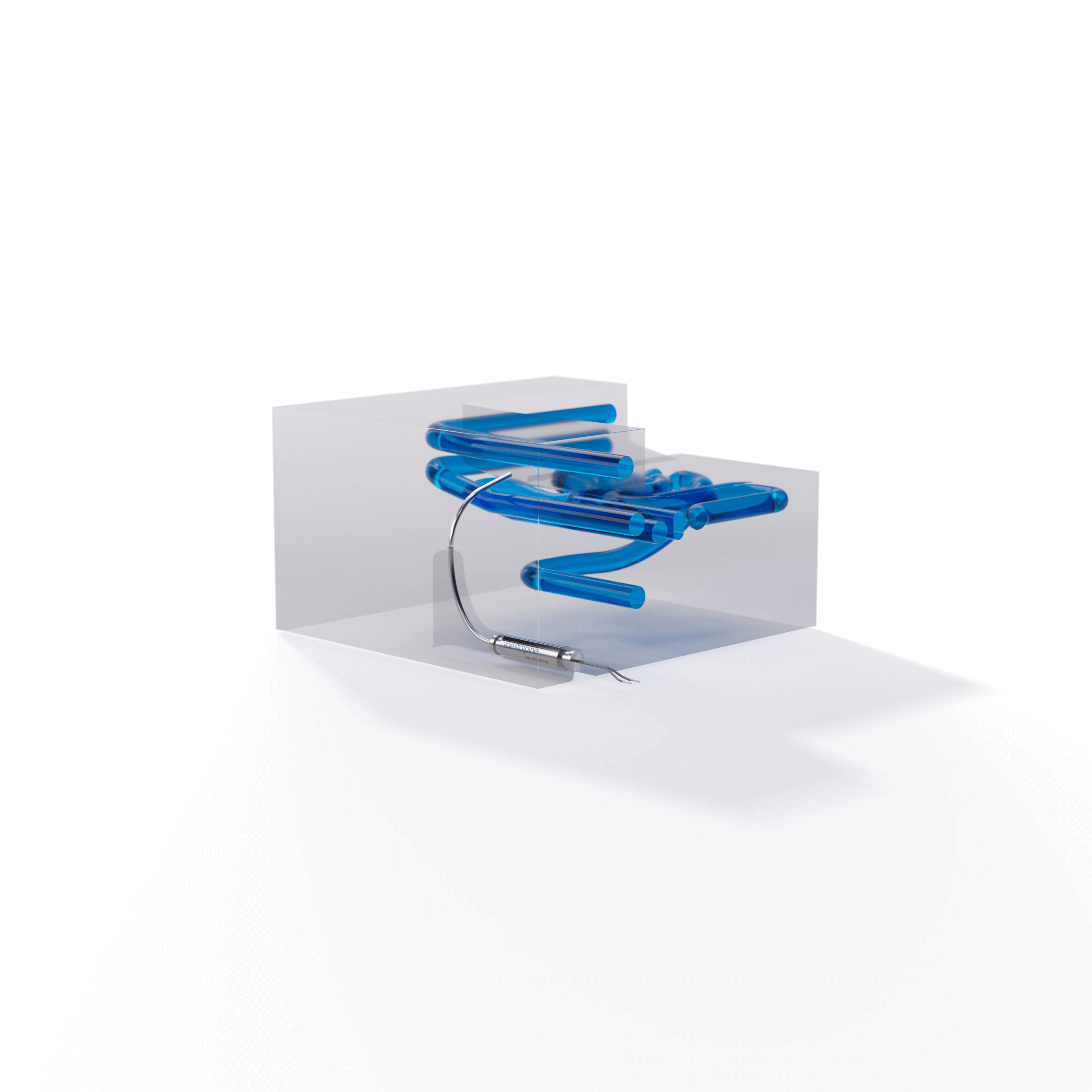

Our Engineered Products for plastic injection molding can optimize productivity through their unique combination of our premium AM powder materials and design features, such as conformal cooling channels (in additively manufactured tooling inserts). These cooling channels enable lower cycle times and provide a more homogenous temperature distribution for reducing scrap rates. AM also allows the creation of venting structures with a microscopic porosity, allowing for a targeted release of compressed air to ensure that the mold remains air free during injection. These structures help to avoid defects caused by the diesel effect, which is a well-known industrial problem. Other innovative AM design possibilities include the use of sensor channels, which can also be created to allow for data acquisition and real-time production monitoring.

Manufactured using our premium materials by BÖHLER / Uddeholm, these Engineered Products offer outstanding polishing characteristics and high corrosion and wear resistance – ensuring a high product lifetime and less maintenance effort. Behind every product, voestalpine HPM provides the full solution, including post-processing technology such as heat treatment and machining, and our value-added services, which encompass coating and texturing.

Starting from the selection of the right material, voestalpine HPM works with our customers along the entire value chain—from concept to final component.

Use Cases for Complete Value Chain Solutions

Find out how tool makers, injection molders and OEMs are leveraging our complete value chain, which combines cutting-edge technology and materials expertise, to realize innovative product design and achieve cost-efficient production.