All Products

Discover our wide array of Engineered Products and find those which best fit your individual needs!

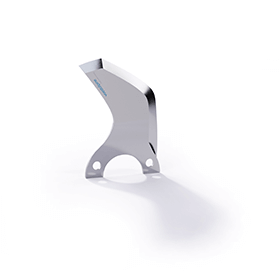

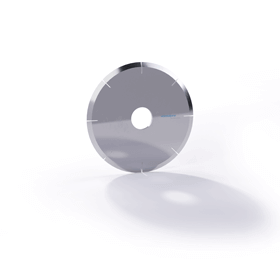

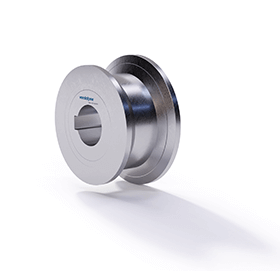

We offer products produced by additive manufacturing (AM) as well as conventional manufacturing processes.

ADDITIVE MANUFACTURING (AM)

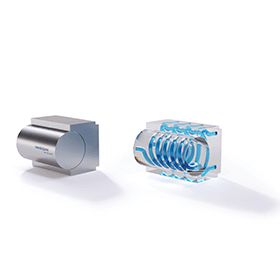

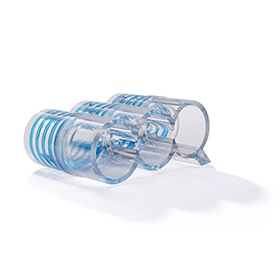

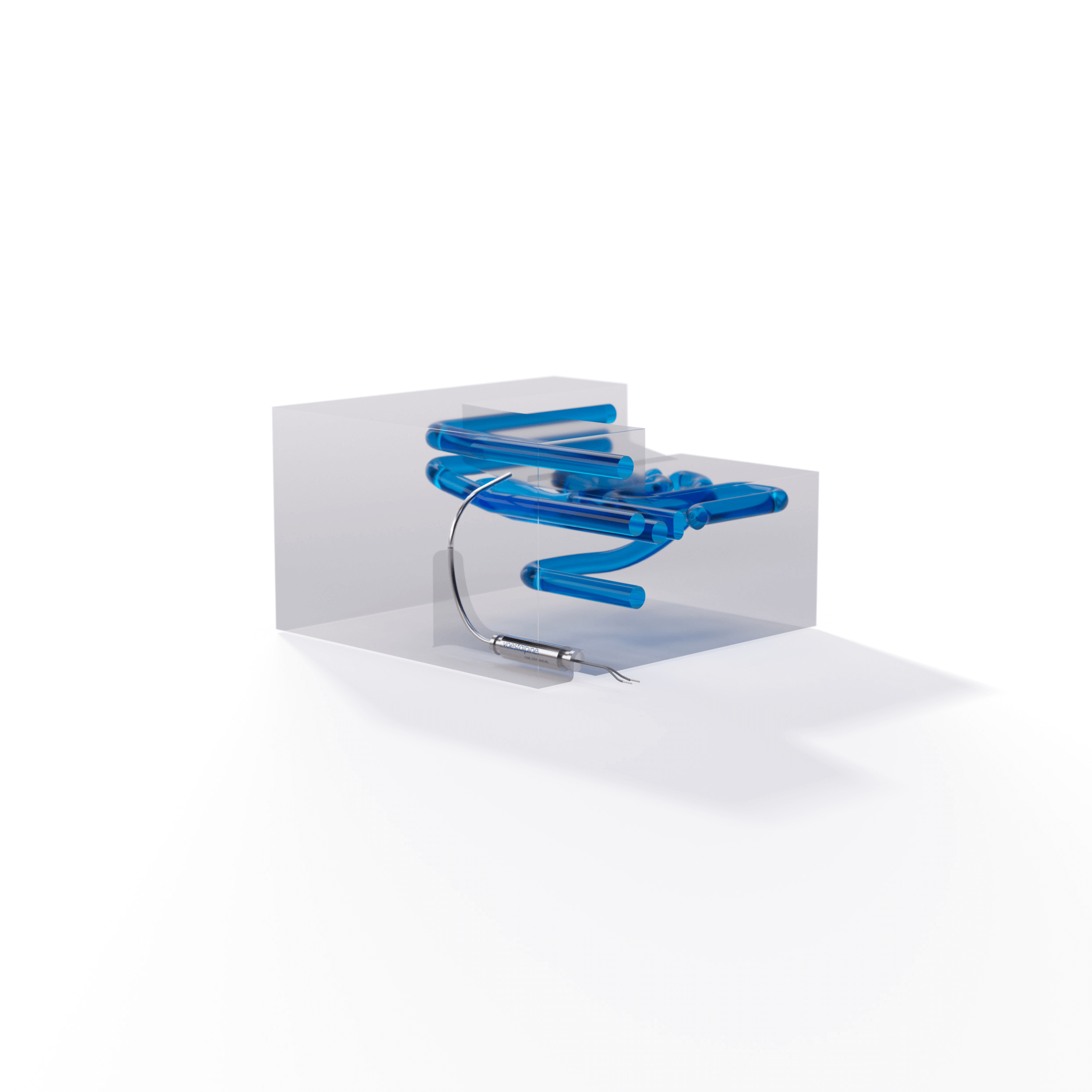

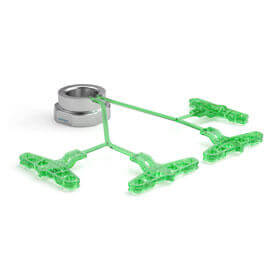

Additive manufacturing is one of the most advantageous production methods for parts with complex shapes and integrated functions, as it pushes the boundaries of conventional manufacturing. Even the most complex structures, such as curved internal channels, can be printed with our premium AM grades by adding metal powder layer by layer.

In high pressure die casting and plastic injection molding, shorter cycle times in part production can be realized using AM’s design capability of creating tailored conformal cooling designs (compared to conventionally manufactured tooling inserts). Conformal cooling also provides a more homogeneous temperature distribution in the mold during the injection process, which reduces distortion and thus can lead to lower scrap rates. AM’s design also facilitates the incorporation of channels for sensor integration without disrupting the temperature control of the mold to provide real-time data and production monitoring capability.

Many of our Engineered Products, for high pressure die casting and plastic injection molding, are available as additively manufactured components.

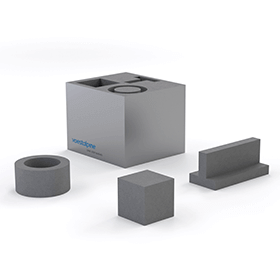

CONVENTIONAL MANUFACTURING

We use state of the art conventional manufacturing processes, combined with voestalpine premium materials and all needed services to produce our Engineered Products. With this unique combination, we create outstanding properties that add value to our customers’ needs.