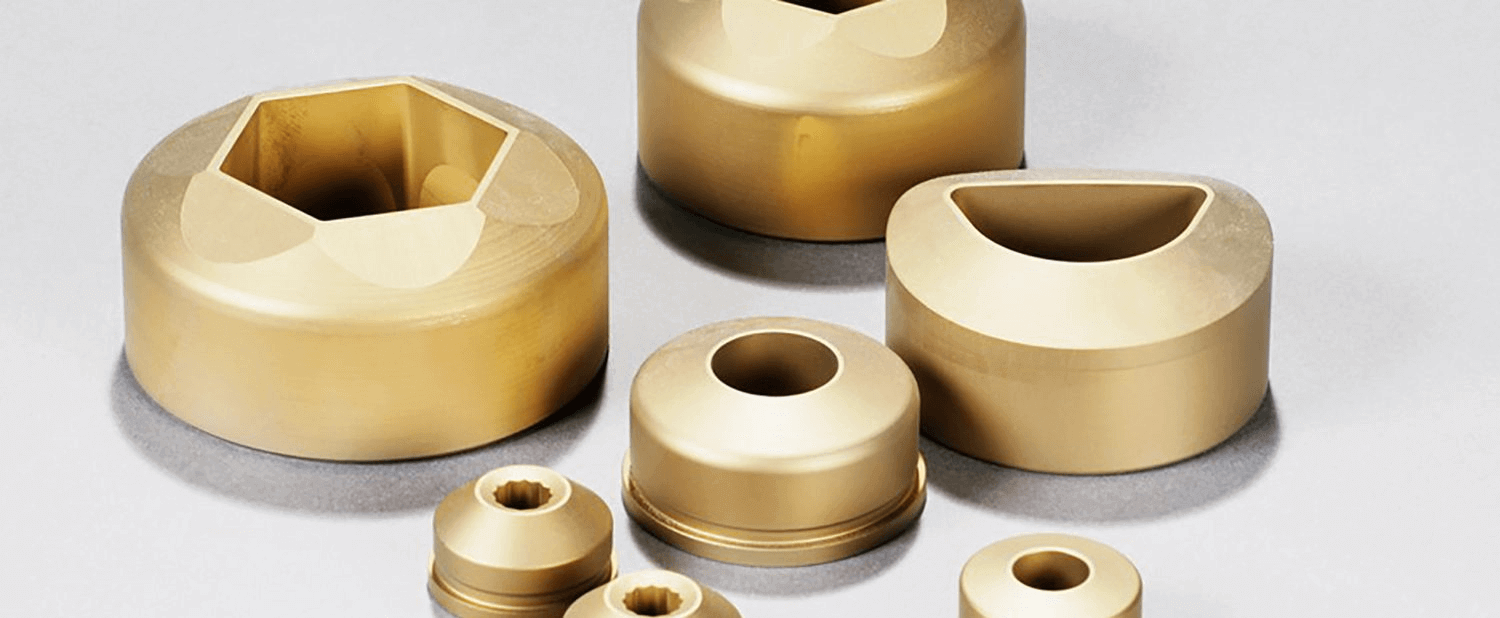

CVD Coating Systems

CVD = Chemical Vapour Deposition, is the deposition of hard coatings in a chemical vapor phase process. At temperatures of approx. 1000 °C, the gaseous coating components flow around the mold and react with elements from the mold surface to form a coating with very high adhesive strength!

CVD Coatings technology and applications

The layer systems ( TiC, TiN/TiC or TiC/TiN) grow with a layer thickness of 7 – 10 µm. Due to the very good adhesive strength combined with very high hardness, these coatings are also referred to as heavy-duty! The chemical process also allows the coating of bores and undercuts in a reproducible way!

This technology still has its place in industrial applications, just as it does in the product range of voestalpine High Performance Metals International GmbH. High-alloy tool steels, HSS and PM materials and also carbides are coated. Steel tools must be subjected to postheat treatment after coating. This must take place in a vacuum, so hardenability in a vacuum is a mandatory requirement for the tool steels to be used.

Particularly because of the required post-heat treatment, the material selection and the processing steps to be matched to the CVD coating are an important issue. With more than 30 years of know-how, we are happy to advise you!

Areas of application for CVD coatings:

Sheet metal forming technology, deep drawing, cold forming, stamping and bending technology and in certain areas of machining technology!

Our Coatings

| CVD Coating | Hardness (HV) | max. Insert- temperature (°C) | Coefficient of friction against steel | Layer thickness (µm) | Color | Application areas | More Information |

|---|---|---|---|---|---|---|---|

| CVD TiC | 3.700 ± 500 | 300 | 0,2 | to 9 | metallic gray | Punching/forming Separation technology | Product information |

| CVD TiC/TiN | 2.700 ± 300 | 500 | 0,6 | 6 – 10 | gold | Machining Punching/forming Separation technology | Product information |

| CVD TiN/TiC | 3.000 ± 300 | 450 | 0,2 | to 10 | metallic gray | Punching/forming Separation technology | Product information |