Was ist Pulverbettschmelzen?

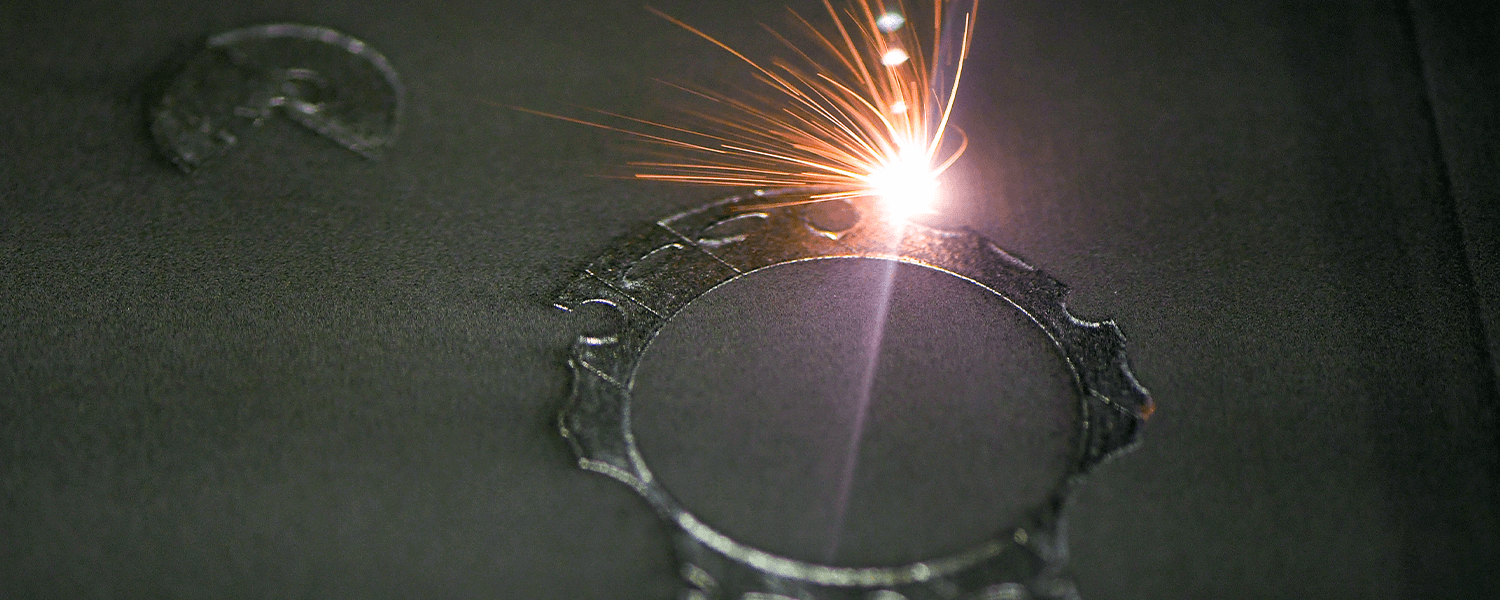

Over the years, our voestalpine team has refined and improved the process of powder bed fusion. In laser beam melting, a component is built up layer by layer from metal powder (grain diameter approx. 15 µm to 55 µm): 1. a laser beam partially melts the top layer of a powder bed, creating the contour of the component. The material solidifies again after melting and forms a solid layer. 2. the next step includes lowering the base plate by one layer thickness (approx. 30 µm to 50 µm) and applying the powder again. 3. Afterwards the contour is re-melted, and the powder grains of the new layer bond with the solidified underlying layer to form a dense component. We repeat this until the component finishes to build up.

At the end, unused powder surrounds it. We therefore remove the powder, sieve it and reuse it. This process is used for particularly fine structures and complicated components that would be impossible to produce using other technologies. However, the production time is longer compared to conventional processes.

APPLICATION AREAS

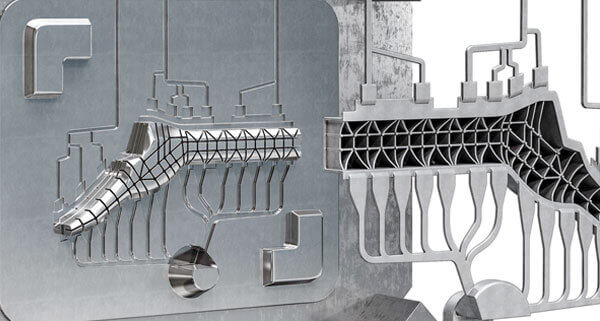

PLASTIC INJECTION MOLDING

In plastic injection molding, cooling is the longest step in the process. This is also the decisive step for the final quality of the injected parts.

Conformal cooling can target hotspots, reduce deformation and shorten cycle times.

DIE CASTING

To optimize the die casting process, we reduce the scrap rate and cycle time and therefore extend the service life.

Additive manufacturing and near-contour cooling are another element to address increasing the quality of cast parts (pore formation), cracking or even shortening the cycle time.

OIL & GAS / MARITIME / MECHANICAL ENGINEERING

We support our customers by advising them to select the right material for the right application. Our team can also help you redesign parts to meet the requirements of your application. The software and advanced technology we use, support the manufacturing process, from initial design to functional parts. You can find more of our Engineered Products here.

OUR BROCHURES

Contact

Ms. Anna Mad

Business Development Manager

3D Printing, Coating & Components

T +43 664 615 6016

anna.mad@voestalpine.com