Additive manufacturing as an approach to reducing overall costs

The next generation of die casting tools

BÖHLER W360 AMPO

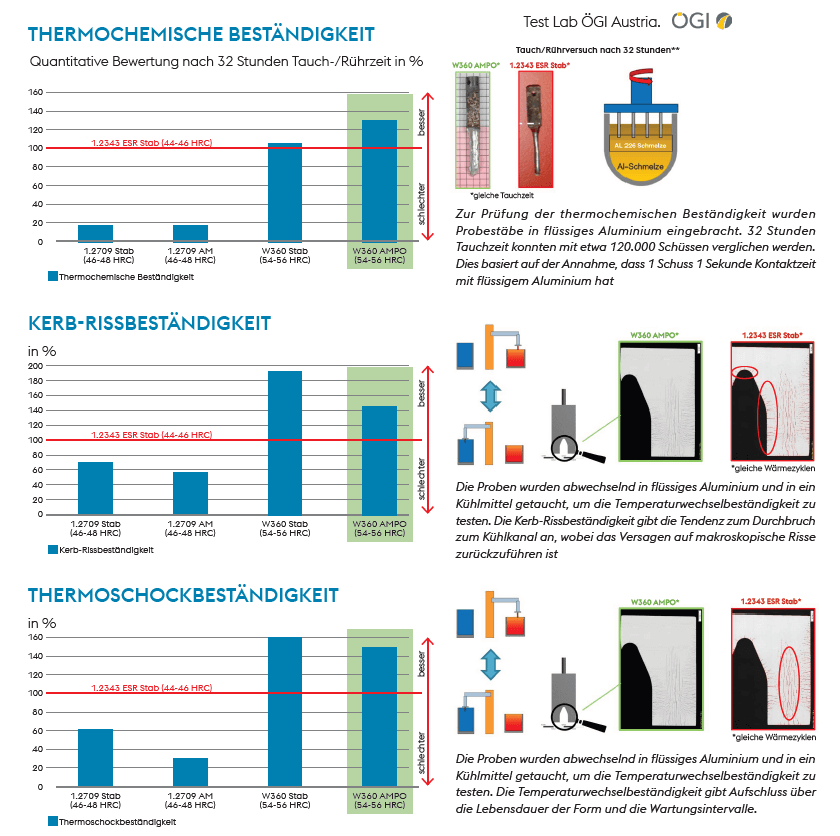

Our long history of developing materials for the die casting industry means that the powders we use are of the highest quality and offer superior tool life. BÖHLER W360 AMPO is our premium quality for die casting applications. This proprietary powder was developed to outperform traditional tool steels such as 1.2343 ESR (H11) and 1.2344 ESR (H13).

We tested bar materials and compared them with the 3D-printed BÖHLER W360 AMPO according to the following test criteria:

» Thermo-Chemical resistance (immersion/stirring test)

» Notch crack resistance

» Thermal shock resistance

All results were compared with the reference values of 1.2343 ESR/H11 rod material (red line in each graph).

BÖHLER W360 AMPO shows exceptional performance compared to traditional tool steels

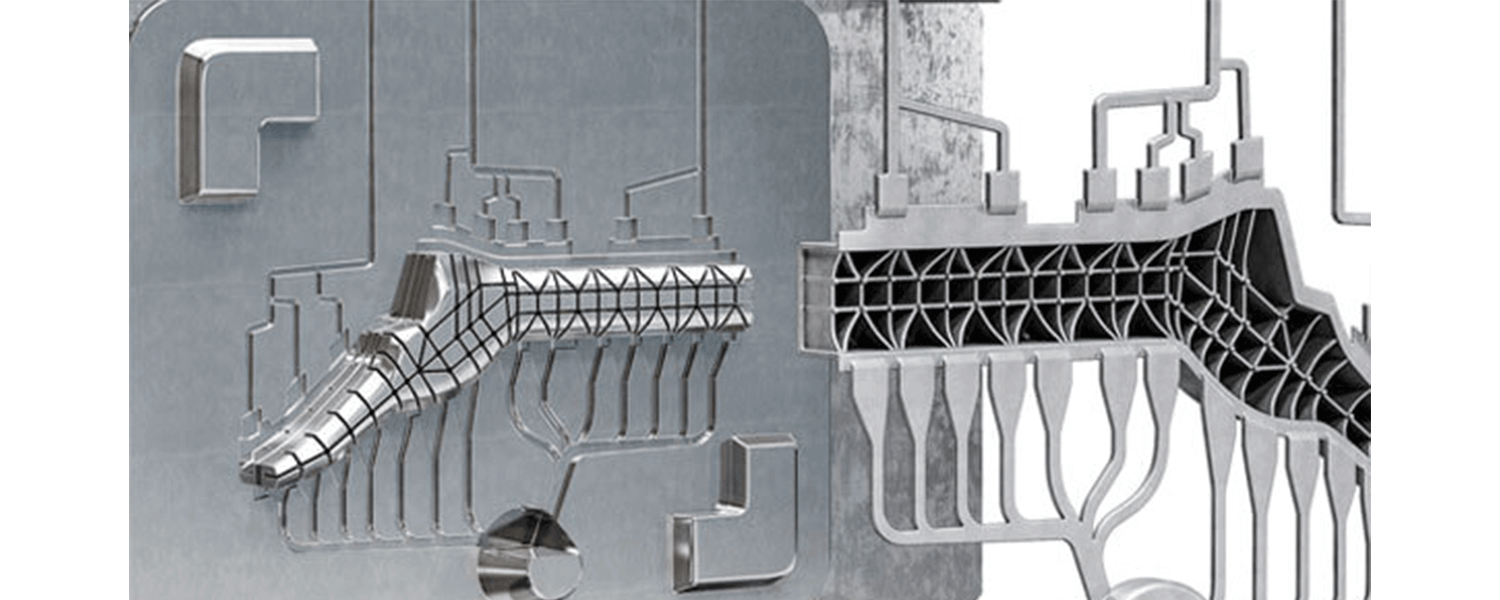

SPRUE MANIFOLD

| Application: Aluminum die casting » Cycle time reduction » Improved life time Performance compared to conventional cooled distributor: Cycle time: -2,5 sec Life time: >200 % |  |

| Application: Aluminum die casting » Cycle time reduction » Improved life time compared to conventional cooled distributor: Cylce time: -3 sec Life time: >150 % |

High Performance AM Manifold & Manifold Ring Solutions

We supply the die casting industry with ready-to-install AM single manifolds and manifold rings. Manufactured from BÖHLER W360 AMPO, these AM parts incorporate our unique internal cooling system designs and have proven to be an excellent solution for effectively removing heat from the tool. Combined with our high-performance alloys, AM is an excellent solution for reducing cycle times and increasing productivity in many die casting applications.

Advantages of our high-performance AM solutions:

- High-performance AM cooling systems improve the rapid solidification of the cast material, resulting in an improved cast structure with fewer defects.

- The lower thermal stress results in longer tool life by reducing sticking, metal corrosion and thermal shock.

- The application of optimized AM cooling solutions to parts in the sprue area results in faster material solidification and helps to reduce cycle time.

- The superior material properties of BÖHLER W360 AMPO significantly improve tool life compared to conventional material grades.

Customer benefits in short

- High tempering and hot wear resistance

- Recommended hardness in use 48 – 56 HRC

- High toughness

- Designed for very demanding mold applications including die casting

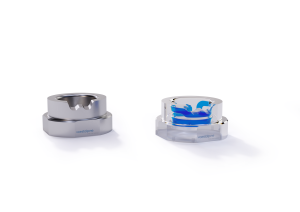

SLIDER

| Application: Coupling housing » Reduction of the reject rate » Improved life time compared to conventional cooled slider: Life time: >600 % |  |

| Application: Gearbox » Reduction of the reject rate » Improved life time Performance compared to conventional cooled slider: Reduction of the reject rate: -10 % |

Contact

Ms. Anna Mad

Business Development Manager

3D Printing, Coating & Components

T +43 664 615 6016

anna.mad@voestalpine.com