Additive manufacturing as an approach to reducing overall costs

The next generation of tools

Applications and solutions

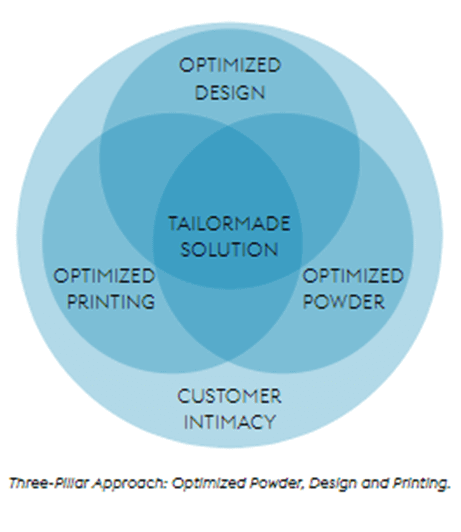

Additive manufacturing – for decades we have been recognized as the world’s leading manufacturer and supplier of tool steel, so we understand the challenges our customers face in the industry. Customer proximity and technical understanding is an important factor in developing successful applications and practical solutions with our partners.

Our attention to detail goes far beyond the design of the tool. Our additive manufacturing experts develop printing parameters optimized specifically for our range of high-performance materials to provide our customers with unique solutions that deliver outstanding results.

Unique tools require unique solutions. In cooperation with our customers and using state-of-the-art additive manufacturing processes and material know-how, we develop customized AM solutions. We create optimized applications which we can use specifically for your company.

Your trusted AM partner

The expertise in additive manufacturing coupled with extensive knowledge in the field of tool steel ensures that we deliver the best possible tooling solutions to our customers. We help our customers develop the right solution for the right application through a detailed consulting process. State-of-the-art tools are used to support the manufacturing process from initial concept to functional parts.

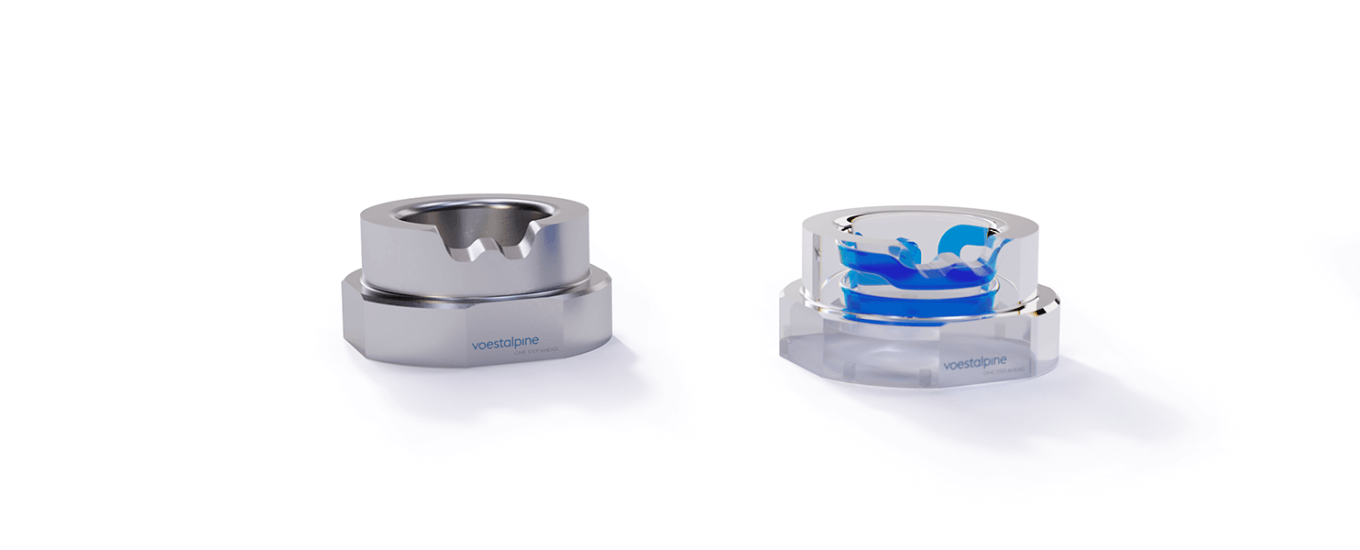

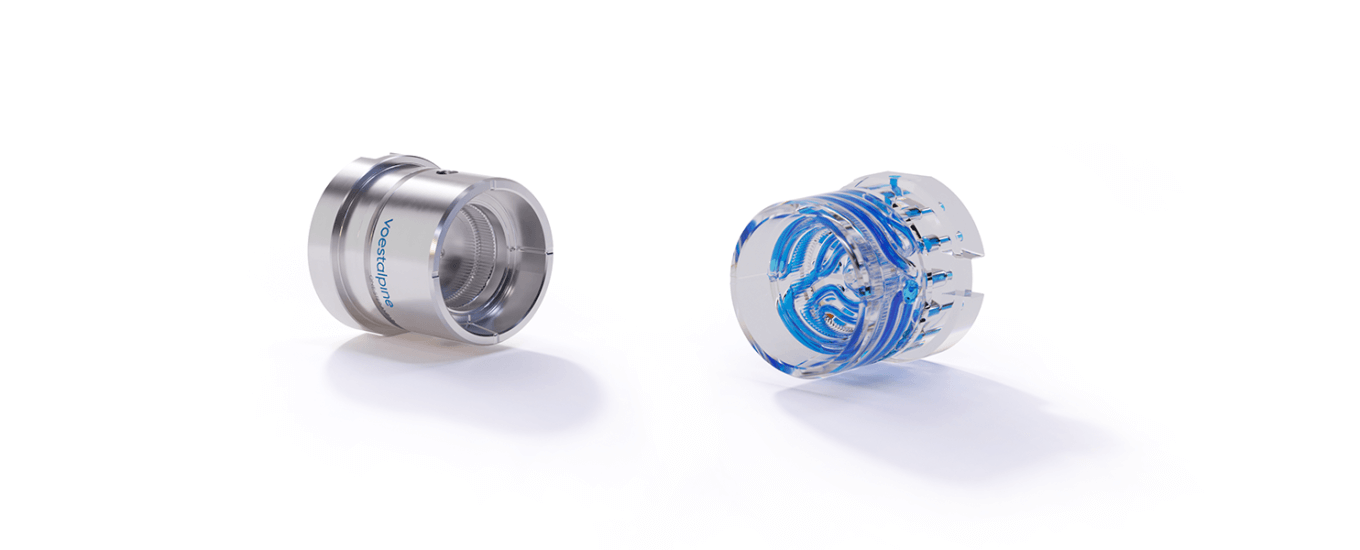

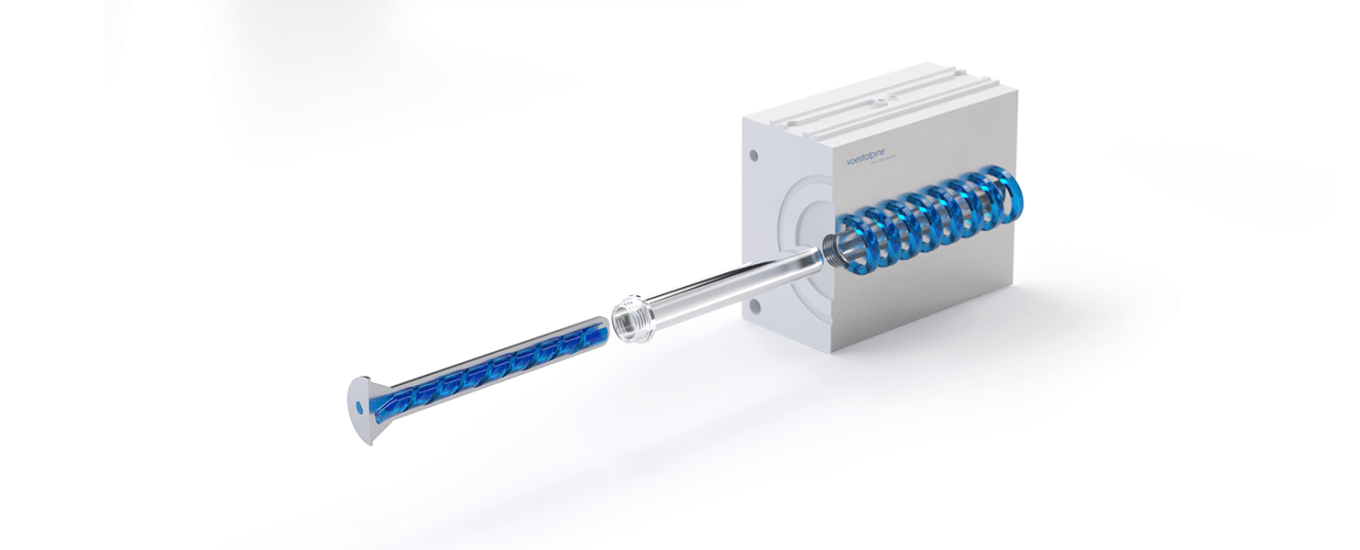

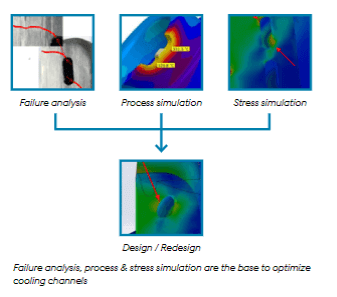

If needed, our experts can help our customers redesign tools to meet the exact requirements of their application. Our data-driven approach to cooling channel design analyzes processing parameters and mechanical loads to develop detailed computer models and process simulations. This method of optimizing thermal management is essential to ensure the right balance between efficient cooling and the mechanical performance of the mold. This process goes far beyond regular near-contour cooling channel design. We understand your application.

We ensure the highest possible quality, reliability, and consistency by controlling every step of the value chain from powder production to delivery of the finished part. Whether single part orders or series production, our internal quality systems ensure that we meet your requirements at all times.

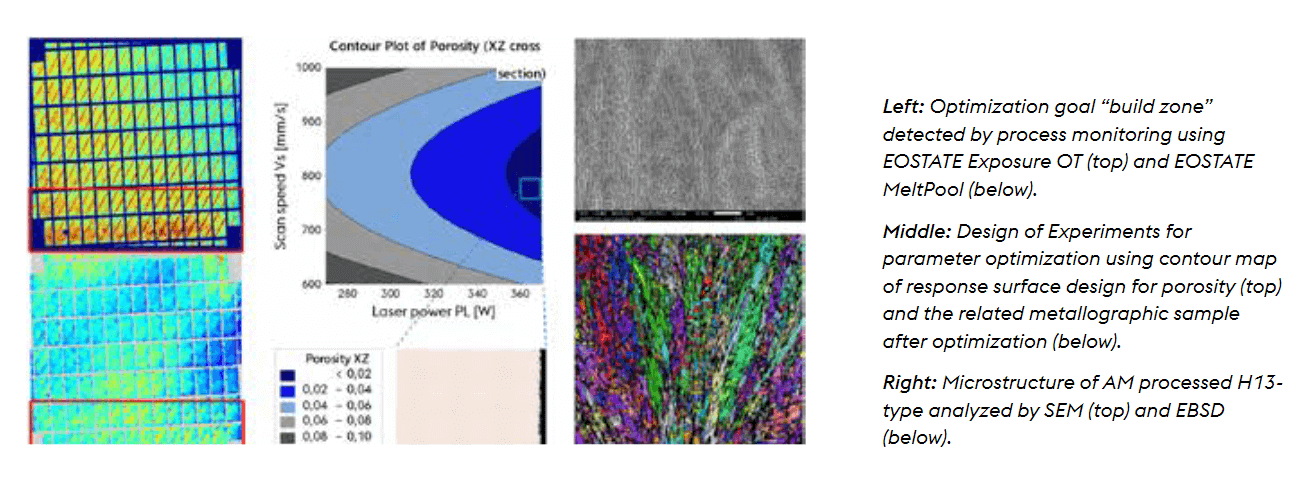

We use state-of-the-art tools to continuously improve and refine our internal printing processes. Design of experiments, statistical process control and process monitoring form the basis of our methodology. Continuous innovation from our AM and materials groups ensures that we deliver superior material properties in the most demanding applications.

We understand the interactions between laser and material. This deep understanding of AM, IM and HPDC enables customers to add value to their business and realize competitive advantage.

Our long history of developing materials for industry means that the powders we use are of the highest quality. Only this way can it provide superior tool life.

As a global steel and technology leader, we offer the full range of production technologies as well as services along the value chain. We therefore support, promote and drive innovation and development based on many years of experience with materials and processing. Starting from alloy development and metal powder production to design, simulation, manufacturing and finishing.

We provide end-to-end solutions to reduce waste and minimize risk in the supply chain. Naturally, our goal is to be your trusted and reliable business partner. We deliver customized solutions from concept to component.

Contact

Ms. Anna Mad

Business Development Manager

3D Printing, Coating & Components

T +43 664 615 6016

anna.mad@voestalpine.com