Innovations in Heat Treatment for Smarter Manufacturing

Heat treatment is a vital process in manufacturing that enhances the properties of metals, ensuring durability, strength, and precision. At voestalpine High Performance Metals International, we lead the way in innovations in heat treatment, enabling smarter, more efficient manufacturing processes. By combining advanced technology with decades of expertise, we are redefining how materials perform under extreme conditions.

Why Heat Treatment Matters in Manufacturing

Heat treatment alters the microstructure of metals to improve their mechanical properties. This process ensures components can withstand heavy loads, high temperatures, and wear over time. From tooling and automotive to aerospace and medical devices, industries rely on heat-treated metals for critical applications. Our goal is to make this process not only effective but also smarter and more sustainable.

Advanced Heat Treatment Methods

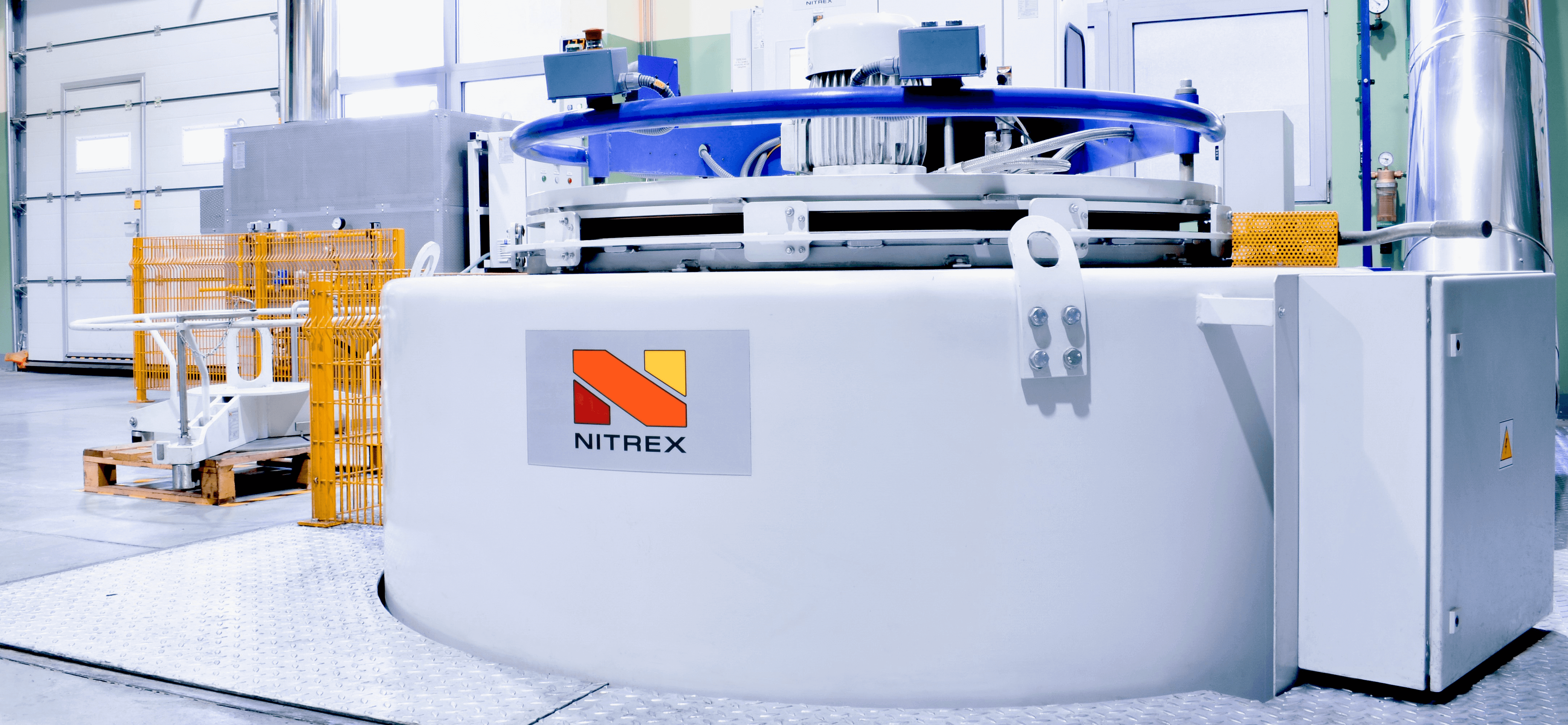

Traditional heat treatment methods, such as annealing and quenching, have long been industry standards. However, we continuously push boundaries to deliver superior results. One of our key innovations in heat treatment is the integration of vacuum technology. Vacuum heat treatment eliminates oxidation during the process, resulting in cleaner surfaces and higher-quality finishes. This method also reduces the need for post-treatment cleaning, saving both time and resources.

Another breakthrough is low-pressure carburizing (LPC). Unlike conventional carburizing, LPC uses lower pressures to achieve precise surface hardening. This process not only improves wear resistance but also minimizes environmental impact by reducing gas consumption.

Smarter Manufacturing with Data-Driven Solutions

Digitalization has transformed heat treatment. At voestalpine, we leverage Industry 4.0 technologies, such as sensors and real-time monitoring, to optimize every step of the process. Our heat treatment facilities use advanced analytics to control temperature, pressure, and timing with unparalleled precision.

This level of control ensures consistent quality across batches, reducing waste and enhancing efficiency. For example, our systems detect anomalies instantly, allowing adjustments to be made without disrupting production. These innovations contribute to smarter manufacturing by increasing reliability and lowering costs.

Energy Efficiency in Heat Treatment

Sustainability is a core focus in all our operations, including heat treatment. Traditional methods often consume large amounts of energy, contributing to high production costs and emissions. To address this, we have developed energy-efficient solutions that align with global climate goals.

Our furnaces incorporate energy recovery systems, capturing heat that would otherwise be wasted and repurposing it for other processes. Additionally, our use of renewable energy sources, such as solar and wind power, further reduces our carbon footprint. These measures demonstrate our commitment to sustainable manufacturing while delivering high-performance results.

Tailored Solutions for Diverse Industries

Heat treatment requirements vary widely depending on the industry. At voestalpine, we offer customized solutions to meet the unique needs of our customers.

For the tooling industry, we provide treatments that enhance toughness and resistance to cracking, ensuring tools perform reliably under stress.

In the aerospace sector, lightweight materials must endure extreme conditions. Our heat treatment processes ensure these components meet stringent safety standards while maintaining their structural integrity. Similarly, for the automotive industry, our advanced heat treatments improve the longevity of gears, shafts, and other critical parts, supporting the shift toward electric and hybrid vehicles.

Collaborating for Innovation

We don’t innovate alone. At voestalpine, we collaborate with customers, research institutions, and industry leaders to advance heat treatment technology. These partnerships allow us to stay ahead of emerging trends and address evolving market demands. For instance, our work with academic institutions has led to breakthroughs in cryogenic treatment, a process that enhances wear resistance and toughness by cooling metals to sub-zero temperatures. This collaboration ensures that our customers benefit from the latest developments in material science.

Benefits of Choosing voestalpine for Heat Treatment

When you partner with voestalpine, you gain access to decades of expertise and cutting-edge technology. Our innovations in heat treatment not only improve material performance but also enhance operational efficiency. We prioritize sustainability, quality, and precision, ensuring that your manufacturing processes meet the highest standards.

Whether you need improved wear resistance, energy efficiency, or tailored solutions for unique applications, our team delivers results you can trust. By choosing voestalpine, you invest in smarter manufacturing and a more sustainable future.

Find out what our heat treatment innovations can do for you!

Are you ready to elevate your manufacturing processes with the latest innovations in heat treatment? Contact us today to learn how our advanced solutions can benefit your business. Let us help you achieve greater efficiency, reliability, and sustainability in your operations.