Vacuum Heat Treatment

HOW TO INCREASE THE SERVICE LIFE OF YOUR TOOLS AND PRODUCTS?

Our vacuum heat treatment process helps you achieve higher strength of material, better wear resistance and improved corrosive behavior of the components.

We can support you with:

- High Pressure Vacuum Hardening (10, 6, 5, 2 Bars)

- Tempering (Vacuum / Atmosphere)

- Annealing (Vacuum / Atmosphere)

- Precipitation Hardening (Aging, Solution Annealing)

- Normalizing / Homogenizing

- Specialized Racking / Fixing

- Maximum load 2.5 ton

In the vacuum heat treatment process, the components in the system are brought to austenitizing temperature in several steps, the so-called holding stages.

These holding stages serve to equalize the temperature between the component edge and the component core. This keeps the introduction of thermal stresses as low as possible. The choice of the necessary austenitizing temperature depends on the material in question and is decisive for the resulting quality and the desired properties.

Quenching is mostly done with nitrogen. The quenching pressure can be up to 20 bar. The vacuum hardening process has little warpage compared to other through hardening processes.

Any distortion that occurs is not only due to the quenching process, but also results from the stresses of mechanical processing introduced before hardening. It is advisable to reduce these stresses by means of an upstream stress relieving process.

Through the vacuum hardening process, the entire component is hardened and, with qualitative hardening, has the required properties over the entire cross-section with qualitative hardening. The component size is therefore limited by the material. After the hardening process, the parts are tempered several times, depending on the material quality, in order to keep the residual austenite content as low as possible. Tempering several times is necessary in order to achieve a low residual austenite content. Any freezing process can be helpful here.

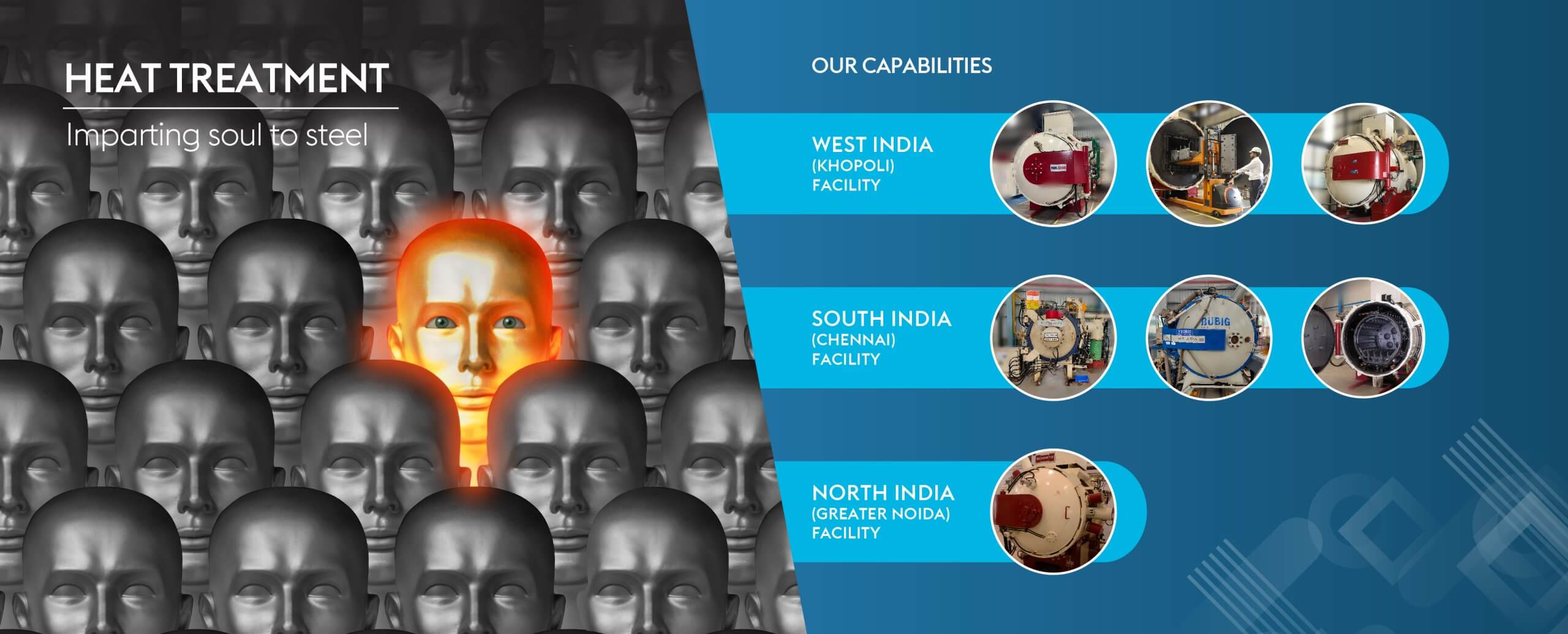

Our Capabilities

voestalpine High Performance India commenced its heat treatment operation in 2004 as at Chennai as on day one besides Chennai we have our facilities at Mumbai and Delhi. All our facilities are set up with the state of art of technology.